Method for preparing lithium ion battery silicon-carbon anode material by using carbon nanotube

A lithium-ion battery, carbon nanotube technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of rapid capacity decay, complex preparation methods, poor conductivity, etc., and achieves low equipment requirements, simple and easy operation, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

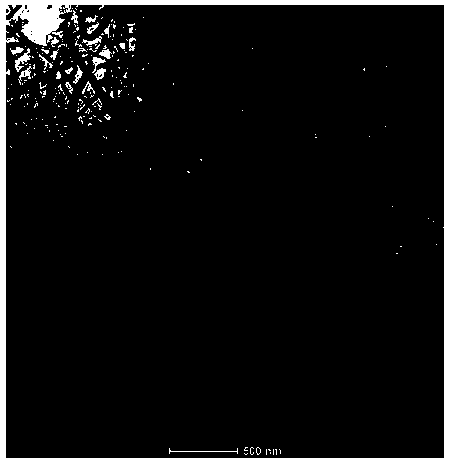

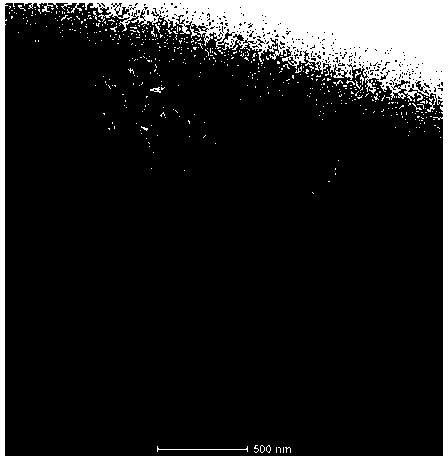

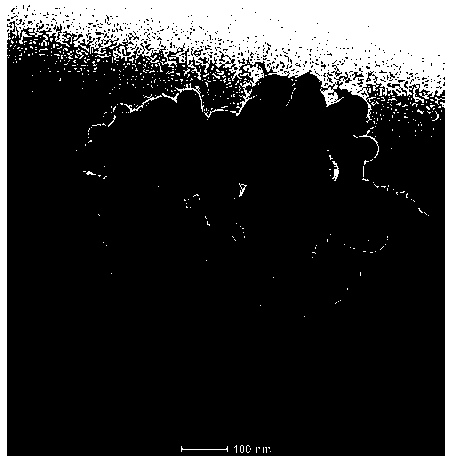

Image

Examples

Embodiment 1

[0027] Embodiment 1: The method for preparing the silicon-carbon negative electrode material of lithium-ion batteries by using carbon nanotubes is as follows:

[0028] (1) According to the mass ratio of silicon powder: multi-walled carbon nanotubes: polyvinylpyrrolidone = 1:0.1:0.1, weigh silicon powder (the particle size of silicon powder is 40nm), multi-walled carbon nanotubes (diameter is 20nm), polyvinylpyrrolidone, put the three in the same beaker, and dissolve them in water with magnetic stirring according to the ratio of mass volume ratio g:mL of 1:50, and then use a high-speed shearing machine to shear at 8000r / min Shear the mixture at a shear speed for 1h to obtain a mixed solution;

[0029] (2) Weigh the sucrose according to the ratio of 1:0.5 mass ratio of sucrose:silicon powder, dissolve the sucrose in water according to the mass ratio of 1:2, stir and mix well, and then add to the mixed solution in step (1) with magnetic stirring Mix well, and place the mixed sol...

Embodiment 2

[0032] Embodiment 2: The method for preparing the silicon-carbon negative electrode material of lithium-ion batteries by using carbon nanotubes is as follows:

[0033] (1) According to the mass ratio of silicon powder: multi-walled carbon nanotubes: polyvinylpyrrolidone = 1:0.2:0.5, weigh silicon powder (the particle size of silicon powder is 60nm), multi-walled carbon nanotubes (diameter is 25nm), polyvinylpyrrolidone, put the three in the same beaker, mechanically stir and dissolve them in water according to the ratio of mass to volume ratio g:mL of 1:70, and then use a high-speed shearing machine to shear at 5000r / min The shear speed shears the mixture for 2h to obtain a mixed solution;

[0034] (2) Weigh the sucrose according to the ratio of 1:2 mass ratio of sucrose:silicon powder, dissolve the sucrose in water according to the ratio of 1:5 and mix mechanically, then add the magnetic Stir and mix well, place the mixed solution in a 70°C water bath for magnetic stirring f...

Embodiment 3

[0037] Embodiment 3: The method for preparing the silicon-carbon negative electrode material of lithium-ion batteries by using carbon nanotubes is as follows:

[0038] (1) Weigh according to the mass ratio of silicon powder: multi-walled carbon nanotubes: polyvinylpyrrolidone = 1:1:1 (the particle size of silicon powder is 80nm), multi-walled carbon nanotubes (diameter is 30nm) , polyvinylpyrrolidone, the three are placed in the same beaker, dissolved in water at a ratio of 1:95 according to the mass volume ratio g:mL, and then the mixture is mixed with a high-speed shearing machine at a shear rate of 3000r / min. Cut for 3h to obtain a mixed solution;

[0039] (2) Weigh the sucrose according to the mass ratio of sucrose:silicon powder of 1:5, dissolve the sucrose in water with a mass ratio of 1:10 and stir it evenly, then add it to the mixed solution in step (1) and mechanically Stir and mix well, place the mixed solution in a water bath at 60°C for magnetic stirring for 8 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com