Battery heat management device

A battery thermal management and heat dissipation device technology, applied in battery/fuel cell control devices, secondary batteries, circuits, etc., can solve the problems of unpowered drainage, environmental pollution, waste of phase change materials, etc., and achieve a good working temperature Environmental protection, saving phase change materials, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

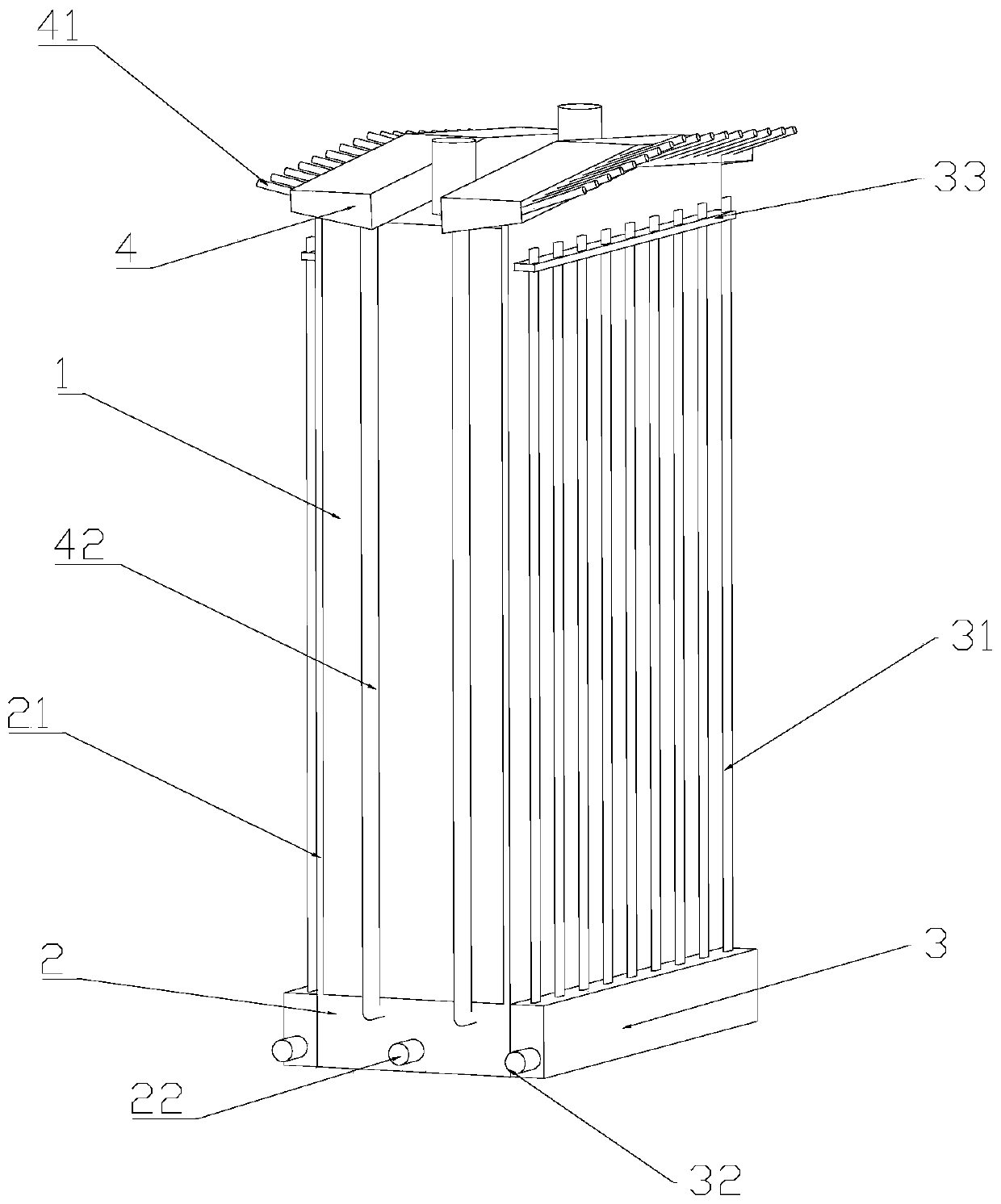

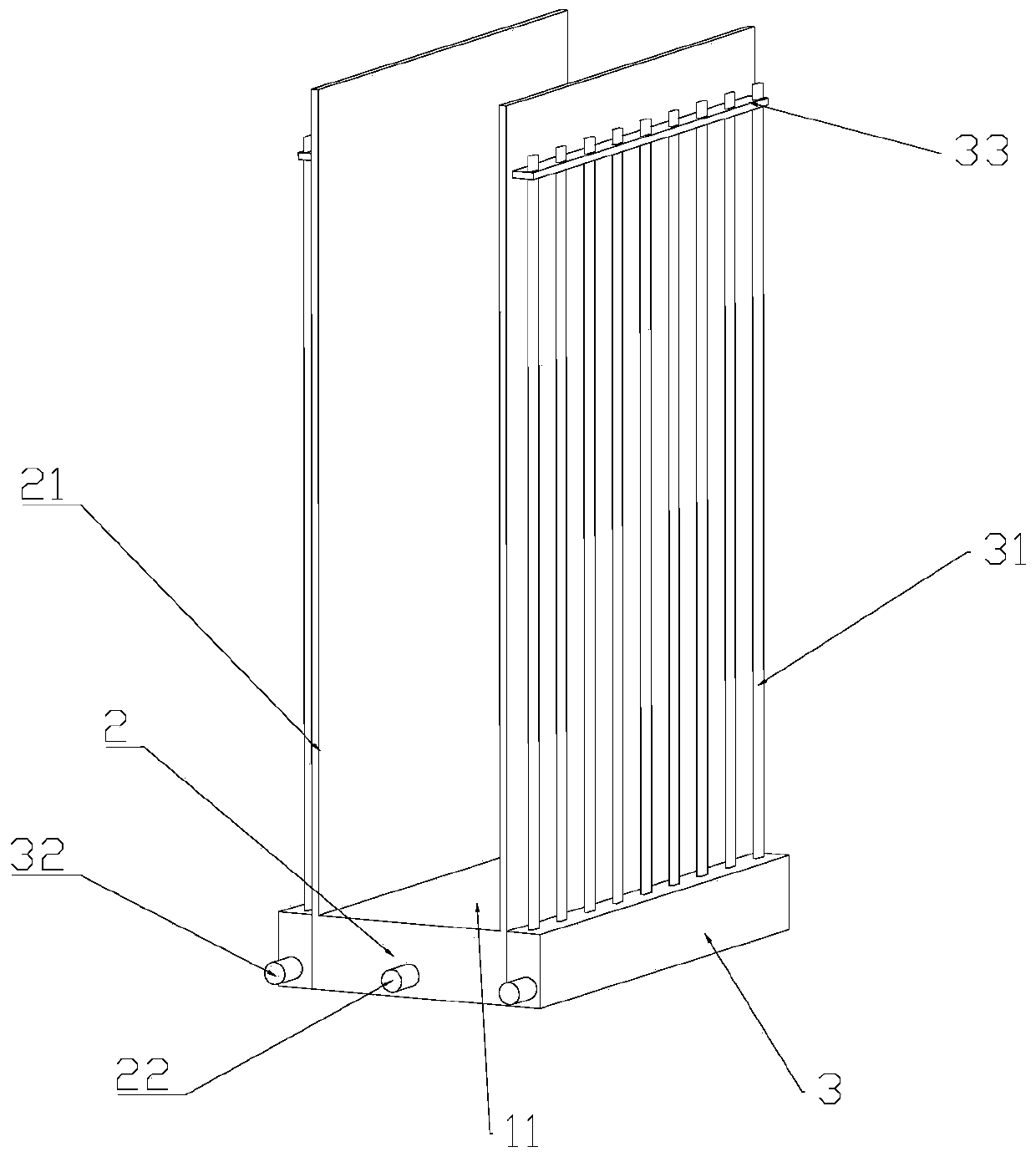

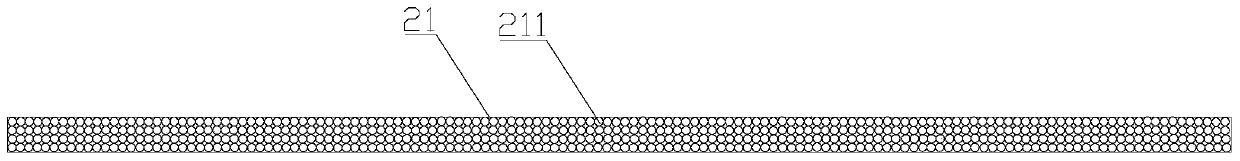

[0025] figure 1 Is a schematic diagram of the overall structure of the present invention, figure 2 Is a schematic diagram of the structure of the heat dissipation assembly of the present invention, image 3 Is a schematic diagram of the structure of the thermally conductive side plate of the present invention, Figure 4 It is a schematic diagram of the structure of the recovery device of the present invention, Figure 5 for figure 1 As shown in the figure, the battery thermal management device in this embodiment includes a first heat dissipation device and a second heat dissipation device. The first heat dissipation device includes a thermally conductive side plate 21 that is thermally conductively attached to the surface of the battery 1 and is vertically arranged The capillary tube 211 inside the heat conducting side plate 21 and the liquid storage bin 2 fixed to the heat conducting side plate 21 and located at the bottom of the heat conducting side plate 21. The liquid storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com