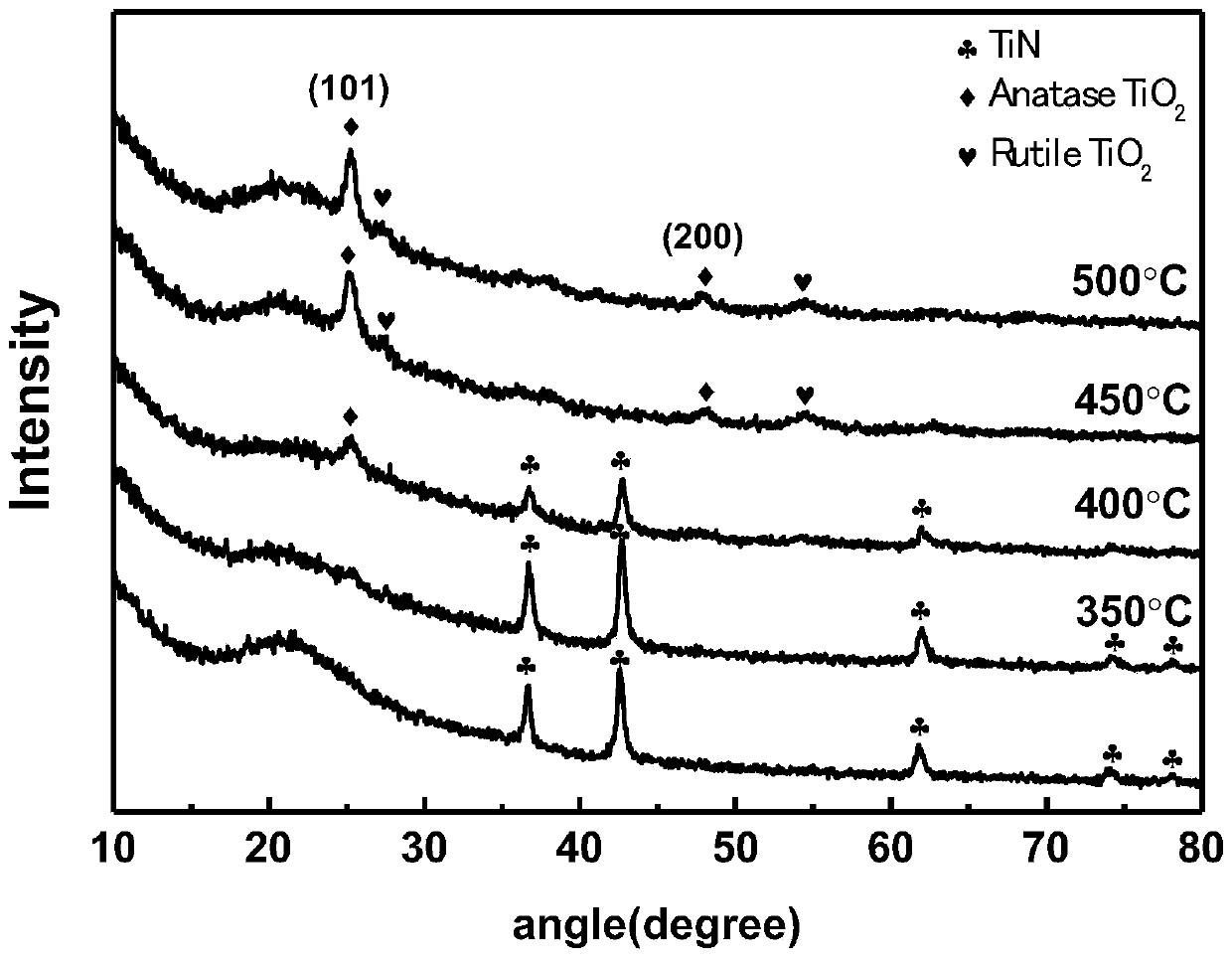

Series type TiN/TiO2 composite film and preparation method and application thereof

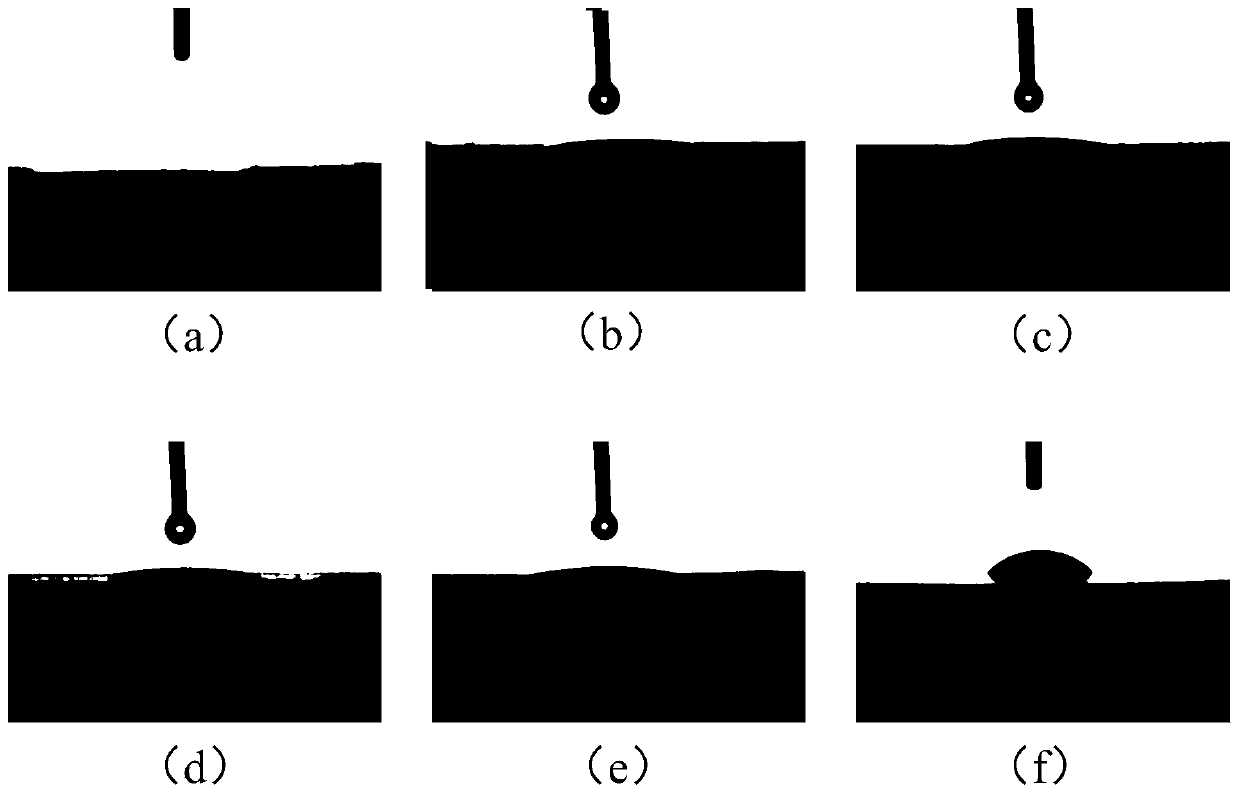

A composite thin-film, tandem-type technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of easy hydrolysis and oxidation, harsh experimental conditions, and danger, and achieve high-efficiency photocatalytic performance and excellent hydrophilicity performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. For the experimental methods without specific conditions indicated in the following examples, the conventional conditions or the conditions suggested by the manufacturer are usually followed.

[0043] (1) The glass substrate was ultrasonically cleaned with surfactant, ethanol, and water for 30 minutes, and then vacuum-dried at 80°C.

[0044] (2) Dispersion aid Tween 80 (C 12 h 10 CINO 3 ) was mixed with TiN powder at a mass percentage of 3%, ball milled for 24 hours, and taken out for use.

[0045] (3) Dispersion aid Tween 80 is dispersed in deionized water with 3% by mass percent of TiN powder after ball milling, and the configuration concentration is 0.2mol L -1 TiN aqueous dispersi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com