Amorphous stabilized nano composite anticorrosive pigment

An anti-corrosion pigment and nano-composite technology, which is applied in the field of material chemistry, can solve the problem that there is no research report on the preparation of amorphous stabilized nano-composite anti-corrosion pigment, and achieve the effects of improving anti-corrosion performance, simplifying the preparation process and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

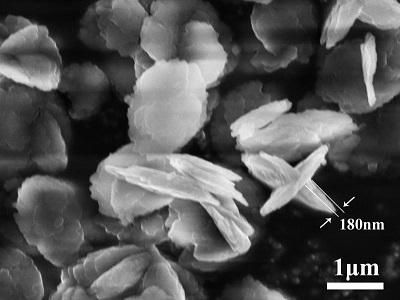

[0020] Prepare zinc nitrate and 0.15 mol / L sodium tungstate solutions with a concentration of 0.15 mol / L respectively, measure 25 mL of the above two solutions and place them in two beakers, add 1.68 mL to the zinc nitrate and sodium tungstate solutions respectively g benzotriazole, stirred until fully dissolved. Add sodium tungstate containing benzotriazole dropwise to the zinc nitrate solution under 500 W ultrasonic conditions. After reacting for a certain period of time, take the precipitate, wash it with deionized water for 3 times and put it in an oven. and dry for 12 hours to obtain an amorphous stabilized nanocomposite anticorrosion pigment. The overall diameter of the obtained amorphous stabilized nano-composite anti-corrosion pigment is about 2.0 μm, and the thickness of the nano-sheets assembled into the nano-assembled flaky anti-corrosion pigment is about 170 nm. The anti-corrosion pigment is added to the paint to make a paint film. The results of the impedance tes...

Embodiment 2

[0022] Prepare zinc nitrate and 0.3 mol / L sodium tungstate solutions with a concentration of 0.3 mol / L respectively, measure 25 mL of the above two solutions and place them in two beakers, add 3.36 mL to the zinc nitrate and sodium tungstate solutions respectively g benzotriazole, stirred until fully dissolved. Add sodium tungstate containing benzotriazole dropwise to the zinc nitrate solution under 700 W ultrasonic conditions. After reacting for a certain period of time, take the precipitate, wash it with deionized water for 3 times and put it in an oven. and dry for 12 hours to obtain an amorphous stabilized nanocomposite anticorrosion pigment. The overall diameter of the obtained amorphous stabilized nano-composite anti-corrosion pigment is about 1.7 μm, and the thickness of the nano-sheets assembled into the nano-assembled flaky anti-corrosion pigment is about 200 nm. The anti-corrosion pigment is added to the paint to make a paint film. The results of the impedance test ...

Embodiment 3

[0024] Prepare zinc nitrate and 0.03 mol / L sodium tungstate solutions with concentrations of 0.03 mol / L respectively, measure 25 mL of the above two solutions and place them in two beakers, add 0.336 g benzotriazole, stirred until fully dissolved. Add sodium tungstate containing benzotriazole dropwise to the zinc nitrate solution under 800 W ultrasonic conditions. After reacting for a certain period of time, take the precipitate, wash it with deionized water for 3 times and put it in an oven. and dry for 12 hours to obtain an amorphous stabilized nanocomposite anticorrosion pigment. The overall diameter of the obtained amorphous stabilized nano-composite anti-corrosion pigment is about 1.7 μm, and the thickness of the nano-sheets assembled into the nano-assembled flaky anti-corrosion pigment is about 160 nm. The anti-corrosion pigment is added to the paint to make a paint film. The results of the impedance test show that the impedance value is as high as 22140 ohm cm after 48...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com