A system for comprehensive utilization of waste tire resources

A waste tire and resource technology, applied in the field of comprehensive utilization system of waste tire resources, can solve the problems of difficult cleaning, affecting transportation, long discharge time of carbon black and steel wire, etc., and achieve the effect of high heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

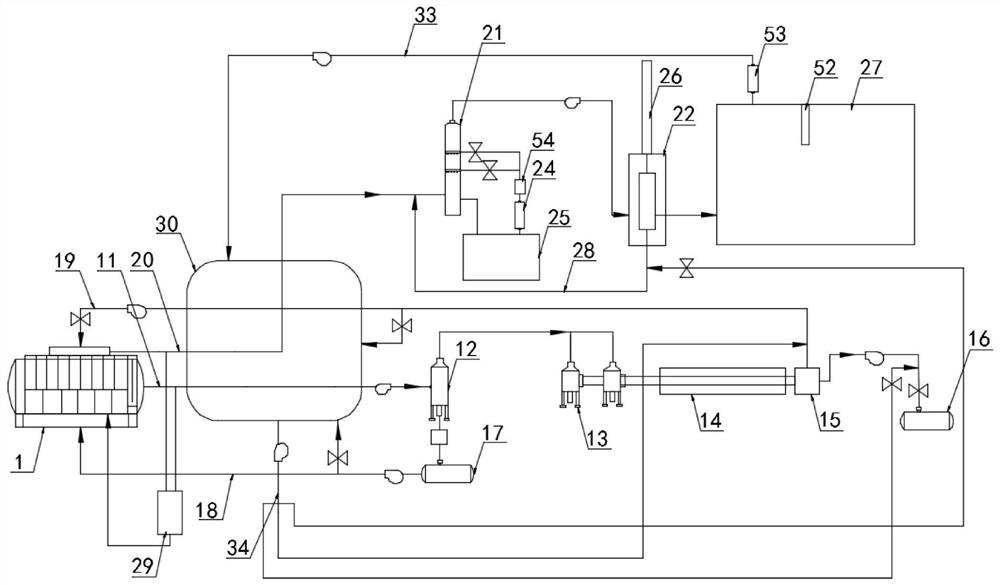

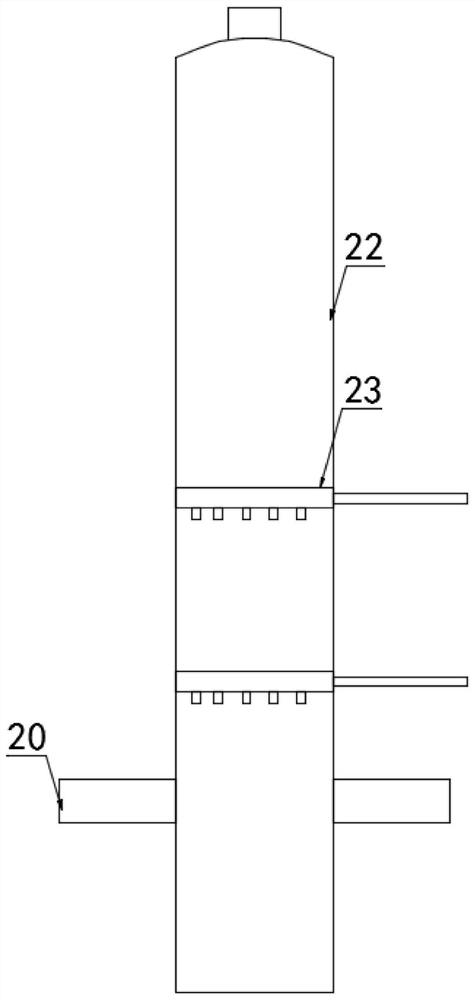

[0034] according to Figure 1-2 The system for comprehensive utilization of waste tire resources shown includes a pyrolysis kettle 1, the pyrolysis kettle 1 includes a frame 2, and the inside of the frame 2 is provided with a stirring box 3 and a combustion chamber 4, and the inside of the stirring box 3 passes The bracket is connected with a carbon wire separation liner 5, the top of one end of the stirring box 3 is provided with an air outlet 6 and the top of the other end is provided with a cleaning return pipe 7, and the front side of the combustion chamber 4 is provided with a gas phase fuel inlet 8 and an oil phase fuel inlet 8. Inlet 9 and exhaust port 10;

[0035] The gas outlet 6 is connected with a gas outlet pipeline 11, and the output end of the gas outlet pipeline 11 is connected with a sub-steam drum 12, a damping tank group 13, a multi-stage circulating cooling pool 14, an oil phase storage tank 15 and a total oil storage tank 16 in sequence, The bottom of the ...

Embodiment 2

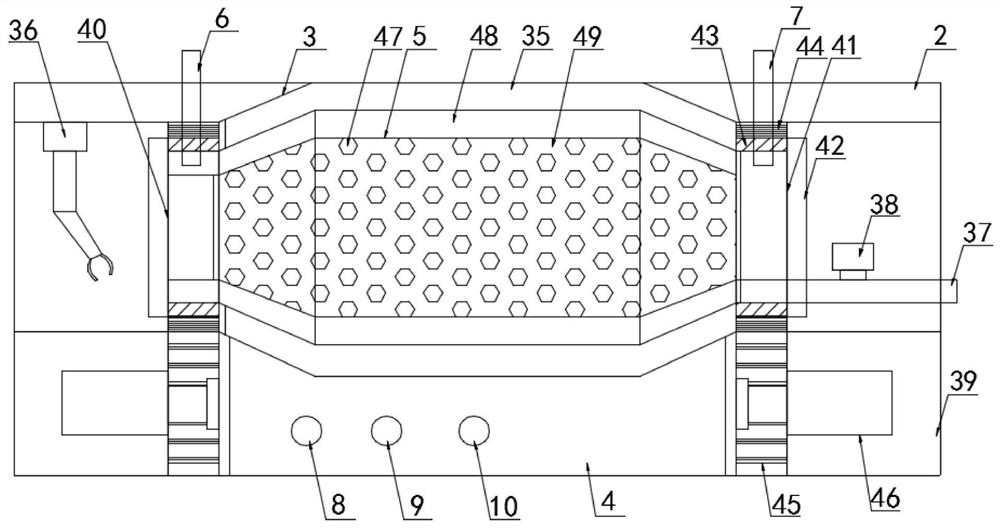

[0045] according to figure 2 In the comprehensive utilization system of waste tire resources shown, a heating chamber 35 is arranged outside the stirring box 3, and the combustion chamber 4 is arranged at the bottom of the stirring box 3 and communicated with the heating chamber 35. One side of the stirring box 3 A loading and unloading mechanical arm 36 is provided and a discharge pipe 37 is provided on the other side, a blower 38 is connected to the discharge pipe 37, and a control box 39 is provided on both sides of the combustion chamber 4;

[0046] One end of the stirring box 3 is provided with a dual-purpose port 40 and the other end is provided with a carbon black discharge port 41, and the outside of the dual-purpose port 40 and the carbon black discharge port 41 is provided with a sealed door 42, and the dual-purpose port 40 and the carbon black discharge port 41 are provided with a sealed door 42. The outside of the carbon black outlet 41 is fixedly set with a ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com