Full-automatic double-station laser marking device and method

A laser marking, double-station technology, applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problem that the size difference of materials cannot be eliminated, and achieve the effect of improving the recognition rate and doubling the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

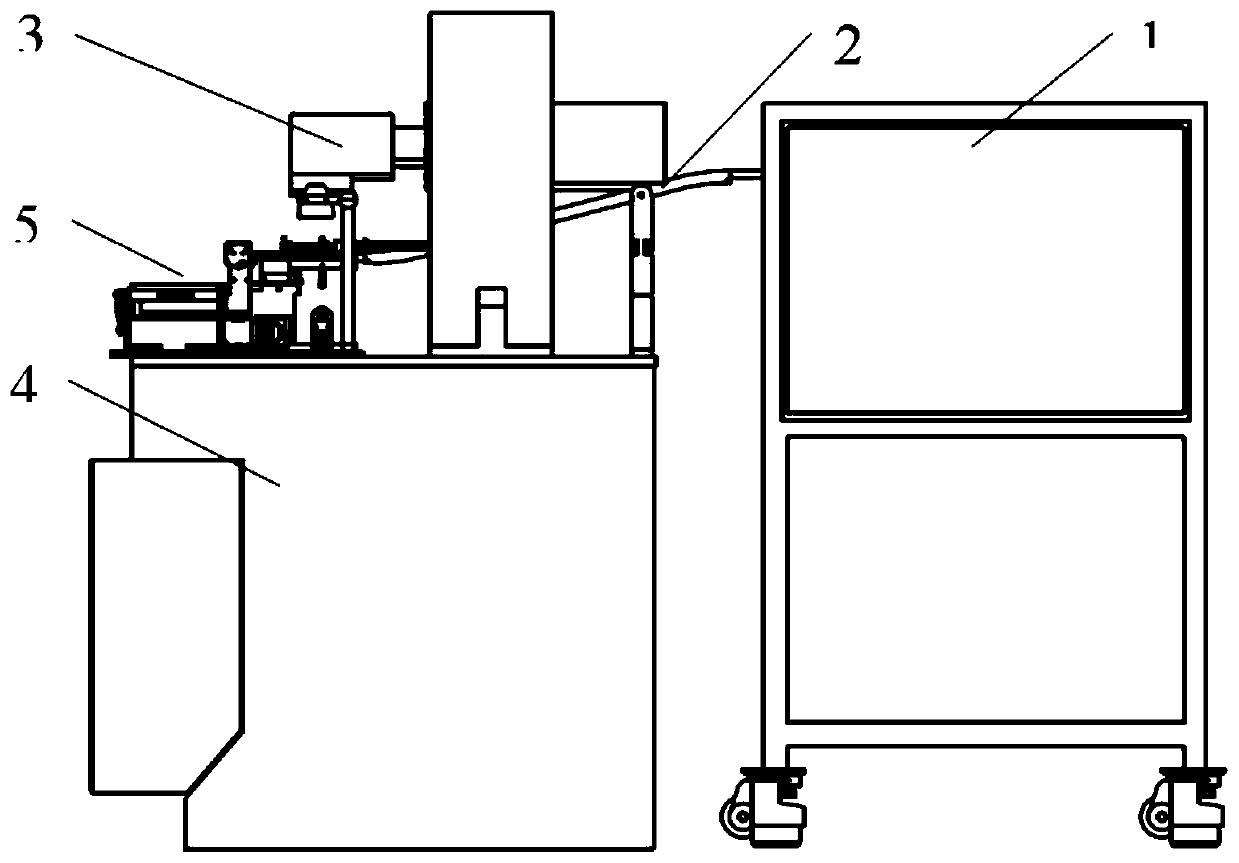

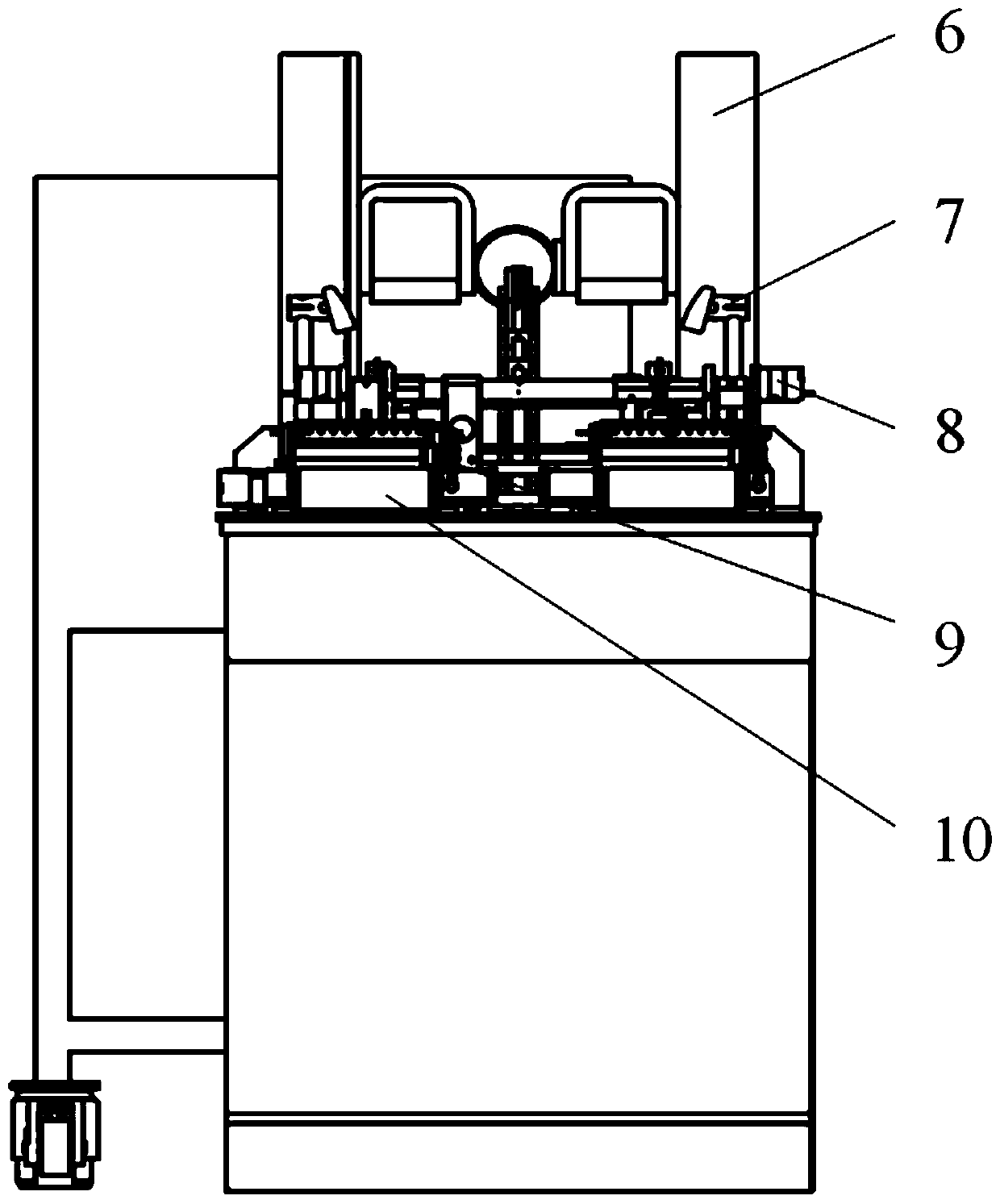

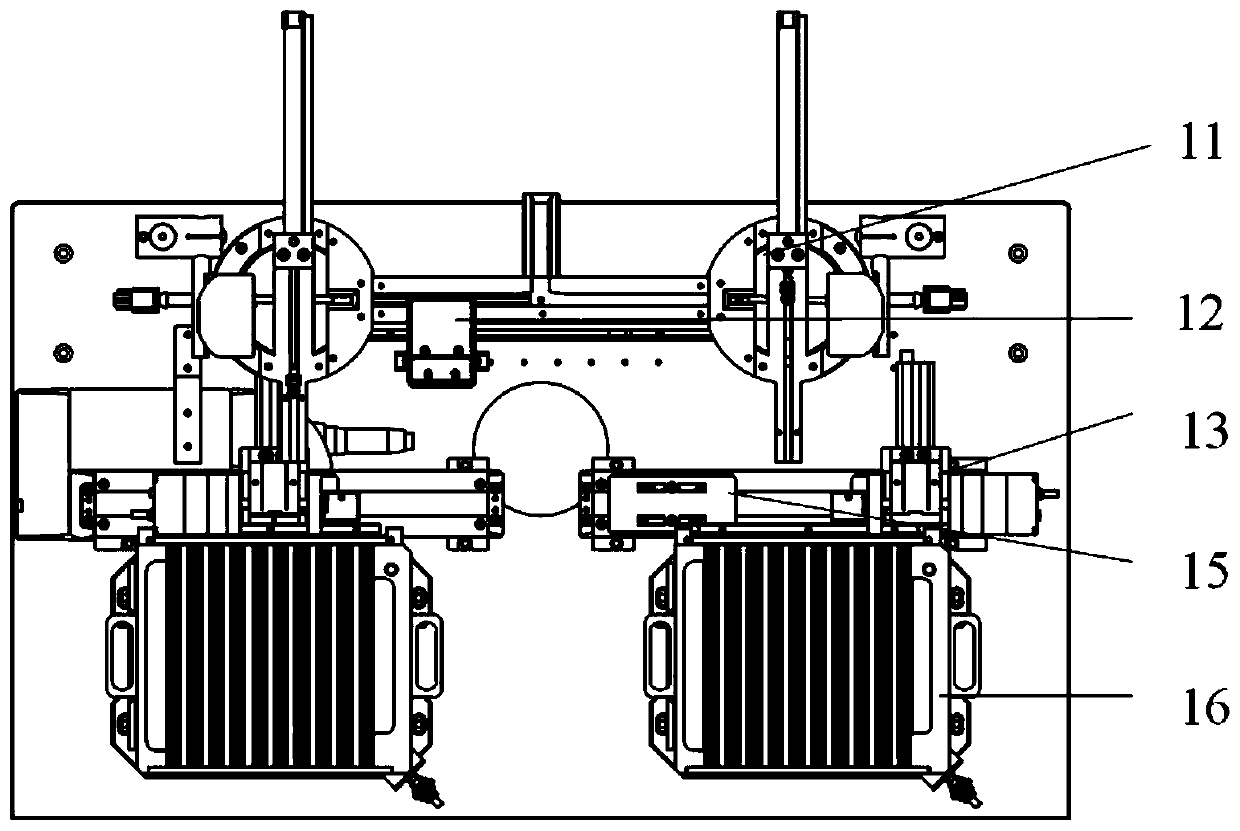

[0020] A fully automatic double-station laser marking device, such as figure 1 and figure 2 As shown, it includes: vibration screening device 1, feeding device 2, laser marking machine lens 3, laser marking machine 4, automatic marking component 5, focus adjustment tooling 6, monitoring device 7, physical reversing mechanism 8, lower Material loading and fixing device 9, tooling and water platform 10, etc., of which:

[0021] A vibrator and a vibrating plate are installed in the vibrating screening device 1, and a certain amount of material is poured into the vibrating plate; the material after vibrating screening is discharged according to the set direction, and the material is transferred to the automatic marking component 5 through the feeding device 2, The material is divided into two stations on the left and right in the automatic marking component and rotates alternately; the laser generated by the laser marking machine 4 marks the material through the laser marking ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com