Process for recovering and refining potassium chloride in organic chemical wastewater

A technology for chemical wastewater and potassium chloride, applied in the direction of alkali metal chloride and the like, can solve the problems of high waste of potassium chloride, high cost and uneconomical, large steam consumption, etc., and achieves fast adsorption rate, high degree of automation, The effect of saving running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

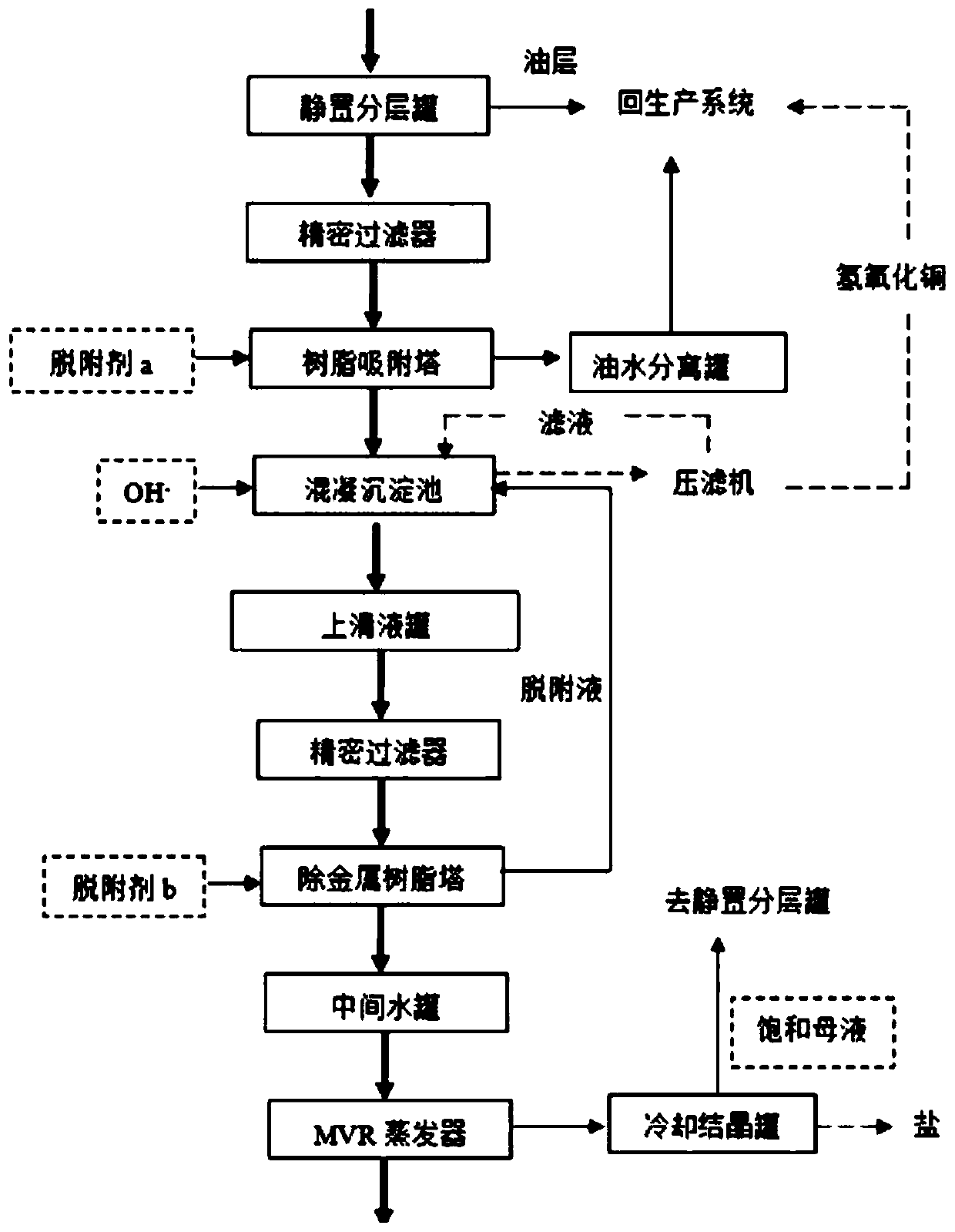

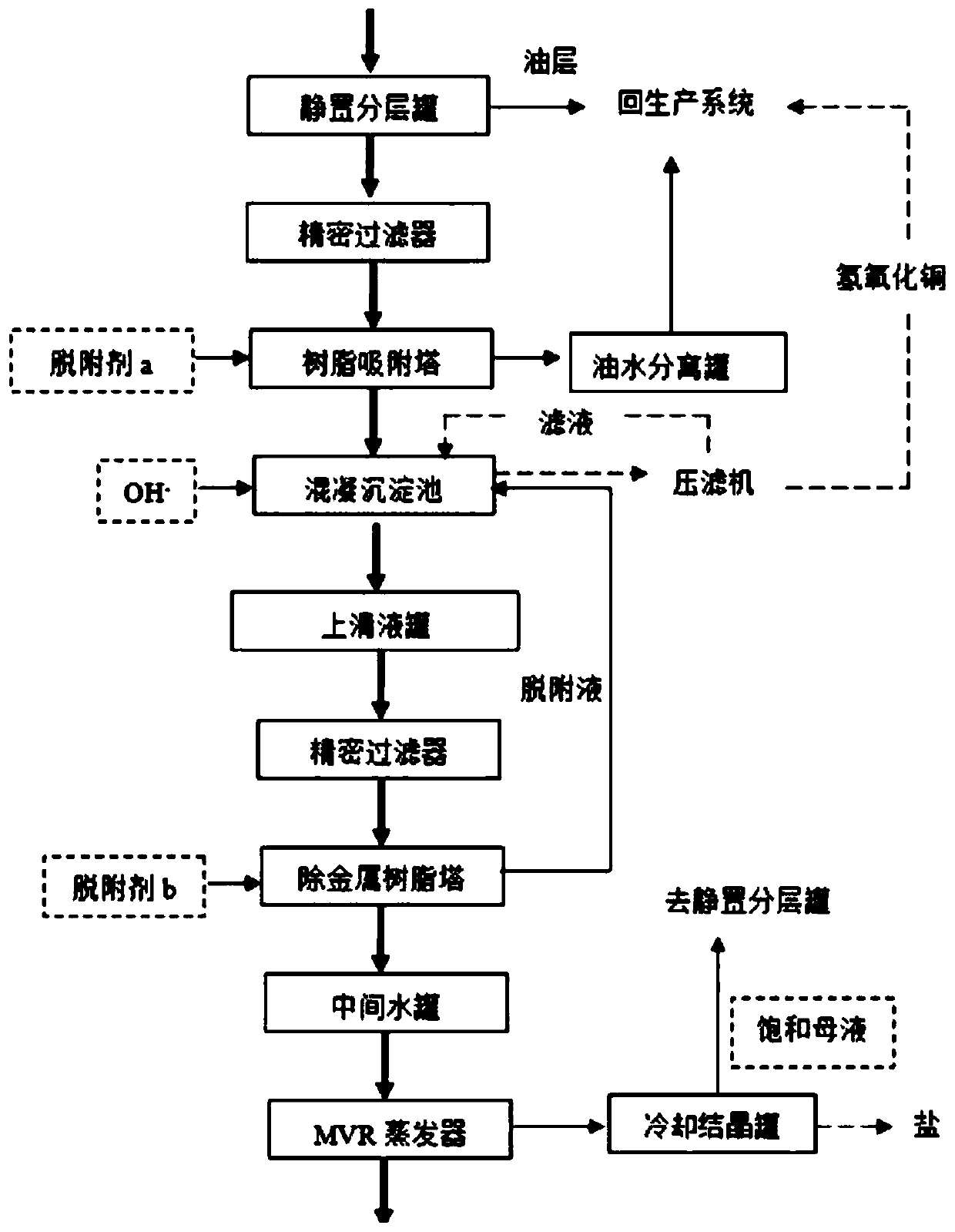

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] A process for reclaiming potassium chloride in refined organic chemical wastewater, comprising the following specific steps:

[0027] (1) Static stratification: put the potassium chloride aqueous solution into the static stratification tank, the water layer and the oil layer are separated, the oil layer is returned to the production system, and the water layer enters the precision filter to filter the water into the resin adsorption tower.

[0028] (2) Resin adsorption: High-efficiency adsorption resin is added to the resin adsorption tower, phenol, chlorobenzene, etc. are adsorbed by the adsorption resin, and the adsorption resin is saturated, and then desorbent a is added to the resin adsorption tower for desorption treatment, and then desorbed with steam The desorption liquid is returned to the production system through the oil-water separation tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com