Preparation method of medical intermediate hexadecahydropyrene

An intermediate and pharmaceutical technology, which is applied in the field of preparation of pharmaceutical intermediate hexahydropyrene, which can solve the problems of coking in the furnace tube, affecting the operation cycle of the device, and high operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

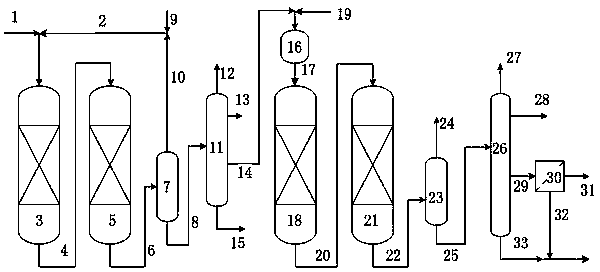

[0063] Such as figure 1 As shown in the flow process, the catalyst in the supplementary hydrofinishing reaction zone is not segmented, but only a kind of catalyst A is used, wherein the operating conditions of the supplementary hydrofinishing reaction zone and the yield and purity of the gained hexadecahydropyrene are as shown in Table 4 Show.

Embodiment 2

[0065] Such as figure 1 As shown in the flow process, the catalyst in the supplementary hydrofinishing reaction zone is not segmented, but only a catalyst B is used, wherein the operating conditions of the supplementary hydrofinishing reaction zone and the yield and purity of the obtained hexadecahydropyrene are as shown in Table 4 Show.

Embodiment 3

[0067] Such as figure 1 In the process shown, the supplementary hydrofinishing reaction zone is divided into two supplementary hydrofinishing reaction stages, and the gradation scheme of catalyst A and catalyst B is adopted. Catalyst A is used in the first supplementary hydrofinishing reaction stage, and catalyst A is used in the second supplementary hydrofinishing reaction stage. Catalyst B was used in the reaction stage, wherein, the operating conditions of the supplementary hydrotreating reaction zone and the yield and purity of the obtained hexadecahydropyrene are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com