Method for producing high-purity 2,4-dichlorophenol

A dichlorophenol, high-purity technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry and other directions, can solve the problems of high production cost and difficult process operation, and achieve the effect of high raw material conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, phenol and chlorine are used as raw materials, and the mixed catalyst is composed of diphenyl sulfide, ferric chloride, and trifluoromethanesulfonic acid. In the mixed catalyst, diphenyl sulfide, ferric chloride, and trifluoromethanesulfonic acid The molar ratio is 2:2:1. The method for producing high-purity 2,4-dichlorophenol in the present embodiment may further comprise the steps:

[0029] (1) 50g of raw material phenol is heated and melted and stirred, and the stirring speed is 2000r / min, and the mixed catalyst prepared in proportion is added to the raw material being stirred, and the addition amount of the mixed catalyst accounts for the raw material in terms of mass percentage 0.05% by weight of phenol;

[0030] (2) Heating the material prepared in step (1) and maintaining it at 70°C, starting to feed chlorine gas slowly and evenly, the feeding time is 3h, and the total amount of chlorine gas feeding is calculated as 2.2 moles of raw material ...

Embodiment 2-5

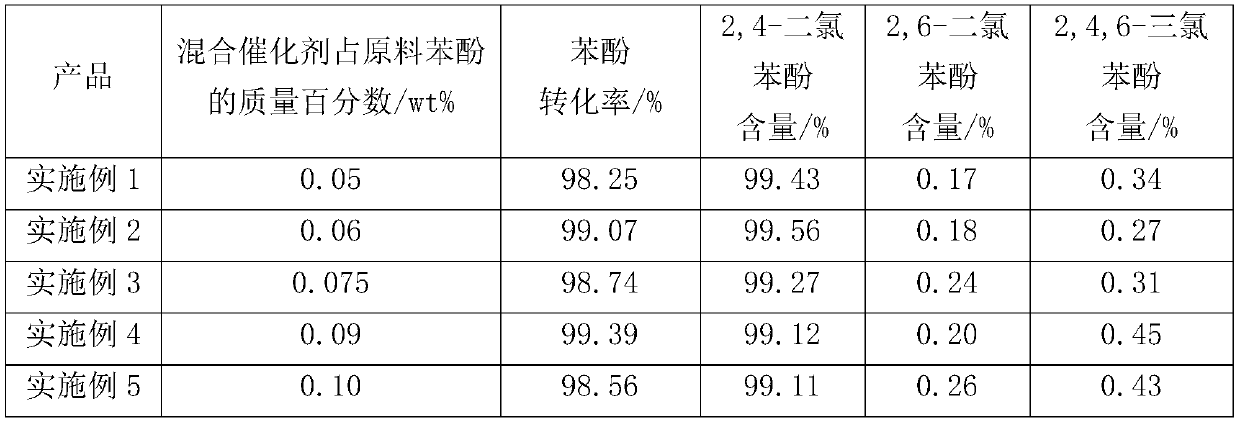

[0033] Embodiment 2-5 only changes the quality of mixed catalyst in example 1, and all the other are the same as example 1, and concrete data see table 1. The 2,4-dichlorophenol products of Examples 1-5 are analyzed by gas chromatography, wherein the gas chromatography conditions are: the temperature of the inlet is 50°C, the temperature of the FID detector is 280°C, and the initial temperature is 50°C. 2min, the final temperature is 260°C, hold for 30min, and the heating rate is 10°C / min. Before analysis, the sample is diluted with solvent to equal multiples, and the solvent used is acetone. The experimental results are shown in Table 1.

[0034] Table 1

[0035]

Embodiment 6

[0037] In this embodiment, phenol and chlorine are used as raw materials, and the mixed catalyst is composed of diphenyl sulfide, ferric chloride, and trifluoromethanesulfonic acid. In the mixed catalyst, diphenyl sulfide, ferric chloride, and trifluoromethanesulfonic acid The molar ratio is 2:2:1. The method for producing high-purity 2,4-dichlorophenol in the present embodiment may further comprise the steps:

[0038] (1) 50g of raw material phenol is heated and melted and stirred, and the stirring speed is 2000r / min, and the mixed catalyst prepared in proportion is added to the raw material being stirred, and the addition amount of the mixed catalyst accounts for the raw material in terms of mass percentage 0.06% by weight of phenol;

[0039] (2) Heat the material prepared in step (1) and keep it at 70°C, start slowly and uniformly feeding chlorine gas for 3 hours, the total amount of chlorine gas feeding is 2.2 times the molar number of raw material phenol, after catalytic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com