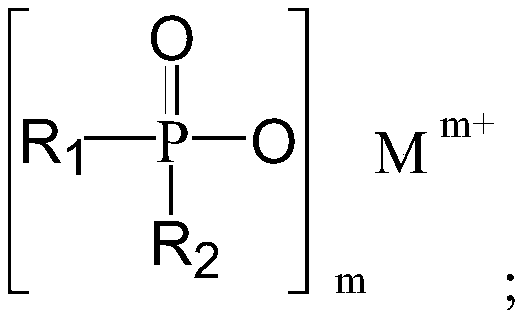

Low-corrosivity dialkyl phosphinate composition and application thereof

A technology of dialkyl phosphinate and alkyl phosphinate, which is applied in the field of flame retardants and can solve problems such as large negative effects and equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

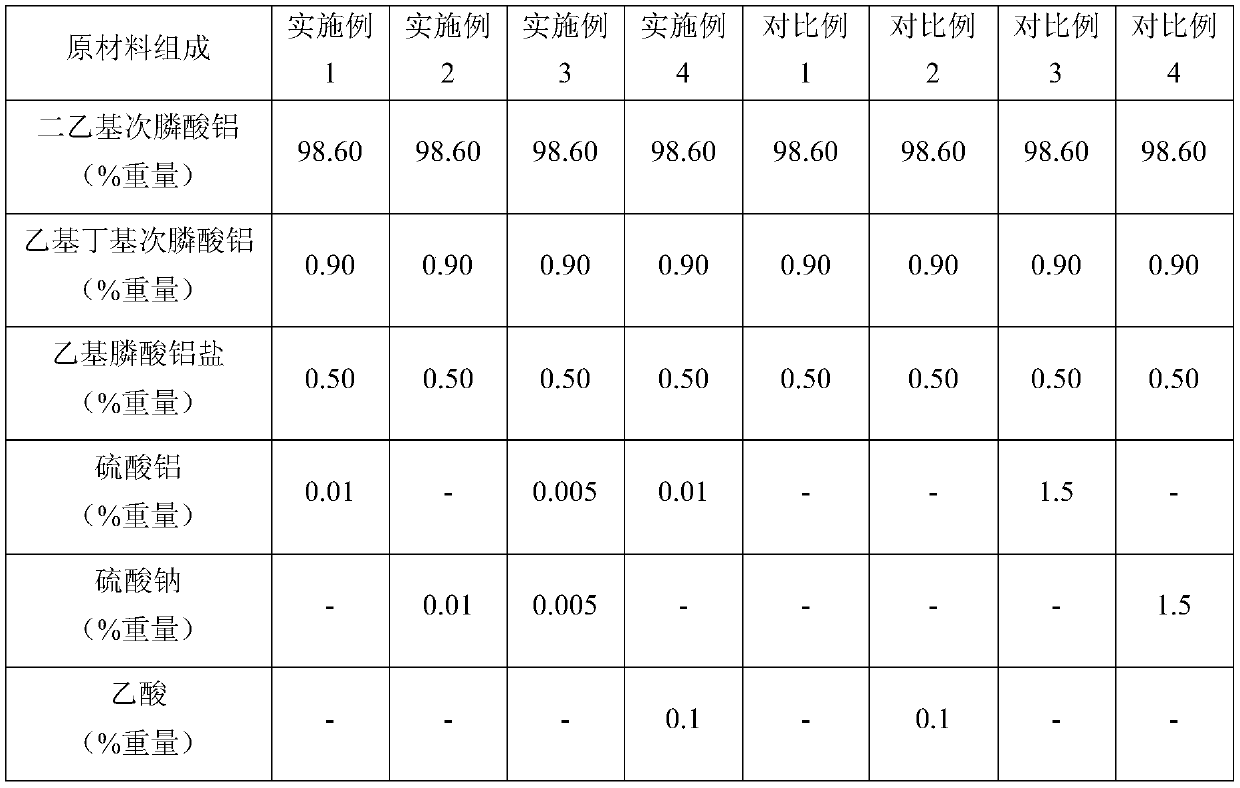

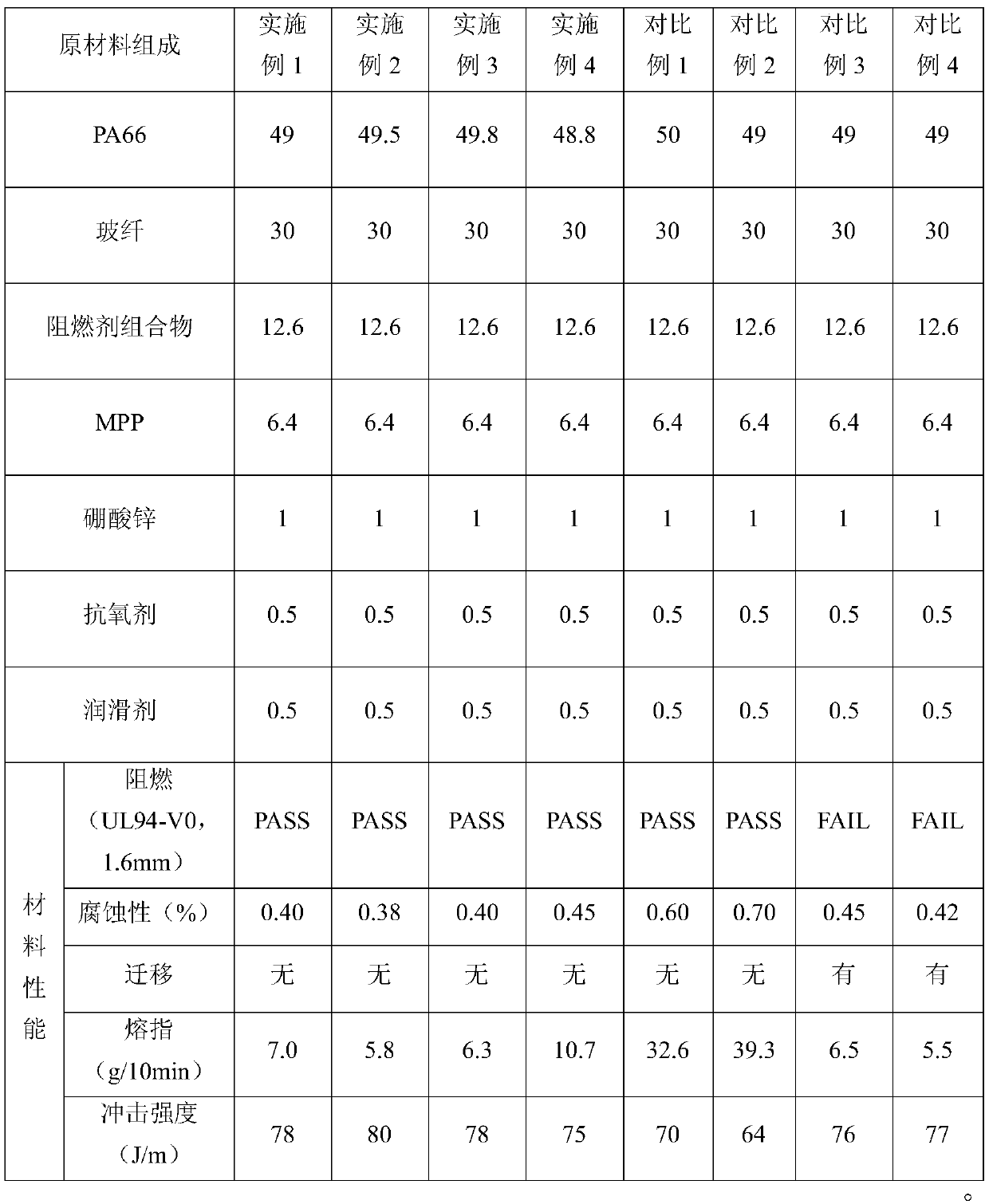

[0056] (1) Mixing of halogen-free flame retardant systems

[0057] Add the pre-weighed components of the compound flame retardant system and other additives into the high mixer, start high-speed stirring, and stir for 10 minutes to complete the blending of the halogen-free flame retardant system and discharge.

[0058] (2) Extrusion granulation of materials

[0059] Set the temperature of each zone of the twin-screw extruder at a predetermined temperature. After the temperature stabilizes for 20 minutes, add the polymer substrate from the hopper, add the glass fiber through the glass fiber inlet, and feed the flame retardant powder through the powder feeding hole, and start The main machine and feeder complete the extrusion and granulation of materials. The granulated materials are sent to the silo through the air conveying system and dried.

[0060] (3) Application and testing of materials

[0061] The dried materials are injected into the injection molding machine to produce standar...

Embodiment 2

[0074] The implementation process is the same as in Example 1, except that aluminum sulfate is replaced with sodium sulfate. The ratio of the dialkyl phosphinate composition is shown in Table 1, and the components and test results of the flame retardant polymer are shown in Table 2.

Embodiment 3

[0076] The implementation process is the same as in Example 1, except that the sulfate is replaced with a mixed sulfate composed of two sulfates. The ratio of the dialkyl phosphinate composition is shown in Table 1, and the components and test results of the flame retardant polymer are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com