High-heat-resistance cold-resistant high-gloss metal-texture spray-free ABS material and preparation method thereof

A technology of ABS material and metal texture, which is applied in the field of high-gloss metal texture spray-free ABS material and its preparation, can solve the problems that the heat resistance and cold resistance of ABS materials cannot be improved at the same time, so as to improve heat resistance, cold resistance, high The effect of cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

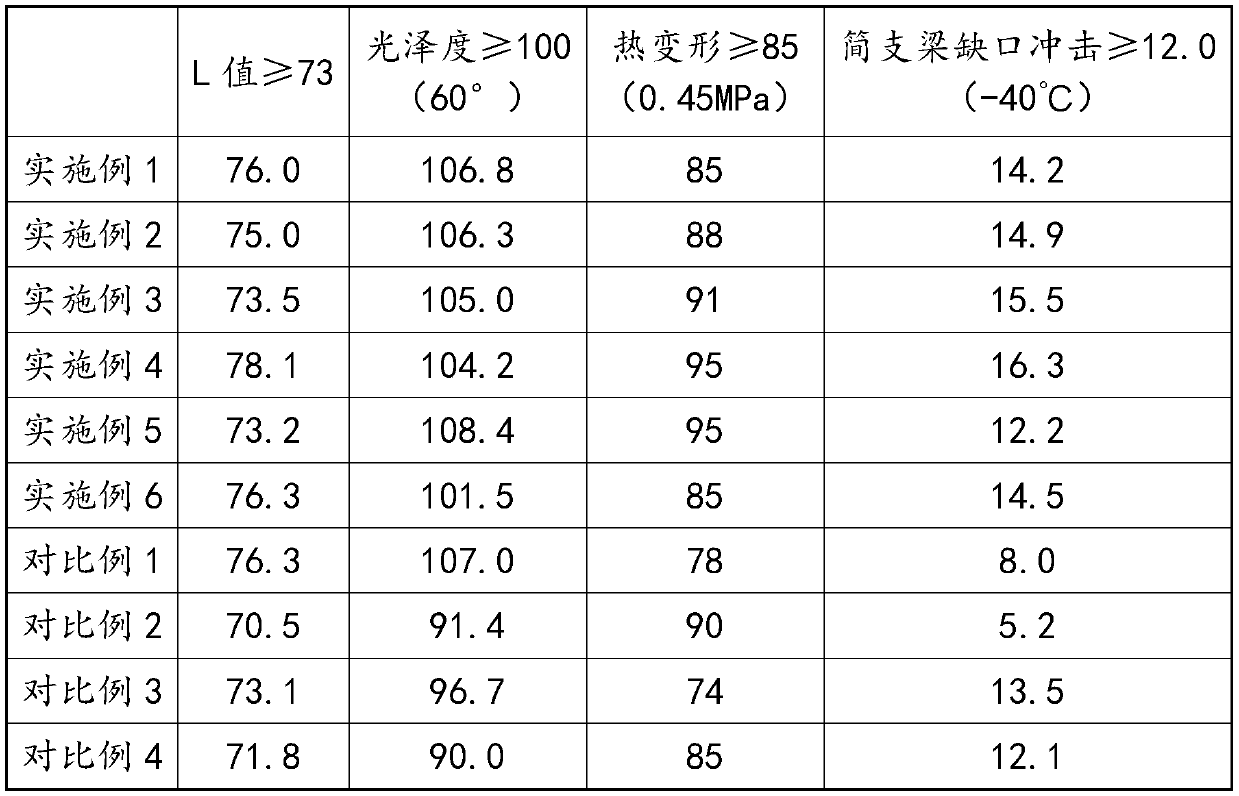

Examples

Embodiment 1

[0034] After dissolving 3% by weight of apel6509 in toluene solution, add it to the reactor under nitrogen atmosphere, add 0.5% by weight of GMA to the reactor, and add 0.2% by weight of TiCl 4 -AlEt 3 Catalyst, heated to 180°C, kept stirring for 40min, filtered out the solid, soaked the filtered solid in acetone for 2h, put it in an oven, and dried it at 60°C to obtain 3.5% by weight COC-g-GMA Grafts; 3.5% by weight COC-g-GMA grafts prepared with 94.2% by weight ABS 757K, 0.1% by weight antioxidant 1010, 0.1% by weight antioxidant 168, 0.1% by weight MB50-001, 2.0 % by weight aluminum silver bar 095-10-E1 was added into the mixer, the speed was controlled at 850 rpm, and the stirring time was 4 minutes; the mixed material was extruded and granulated through a co-rotating twin-screw extruder.

Embodiment 2

[0036] After dissolving 6% by weight of apel6509 in toluene solution, add it to the reactor under nitrogen atmosphere, add 0.6% by weight of GMA to the reactor, and add 0.35% by weight of TiCl 4 -AlEt 3 Catalyst, heated to 190°C, kept stirring for 50min, filtered out the solid, soaked the filtered solid in acetone for 3h, put it in an oven, and dried it at 70°C to obtain 6.6% by weight COC-g-GMA graft. The 6.6% by weight COC-g-GMA graft and 90.9% by weight ABS757K, 0.15% by weight antioxidant 1010, 0.15% by weight antioxidant 168, 0.2% by weight MB50-001, 2.0% by weight pearlescent 5411 were added Into the mixer, control the rotation speed of 850rpm, and stir for 4min; extrude the mixed material through a co-rotating twin-screw extruder to granulate.

Embodiment 3

[0038] After 9% by weight of apel6509 is dissolved in toluene solution, it is added to the reactor under nitrogen atmosphere, 0.8% by weight of GMA is added to the reactor, and 0.5% by weight of TiCl is added 4 -AlEt 3 Catalyst, heated to 200°C, kept stirring for 60min, filtered out the solid, soaked the filtered solid in acetone for 4h, put it in an oven, and dried it at 80°C to obtain 9.8% by weight COC-g-GMA graft. The obtained 9.8% by weight COC-g-GMA graft and 87.4% by weight ABS 757K, 0.2% by weight antioxidant 1010, 0.2% by weight antioxidant 168, 0.4% by weight MB50-001, 2.0% by weight aluminum silver Add strip 095-10-E1 into the mixer, control the speed at 850rpm, and stir for 4 minutes; extrude the mixed material through a co-rotating twin-screw extruder to granulate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com