High-thermoplasticity foam polyester

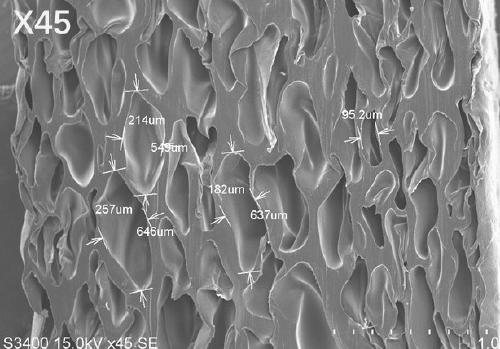

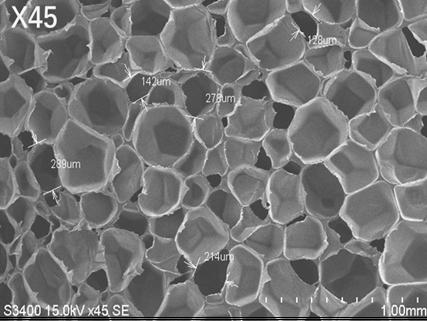

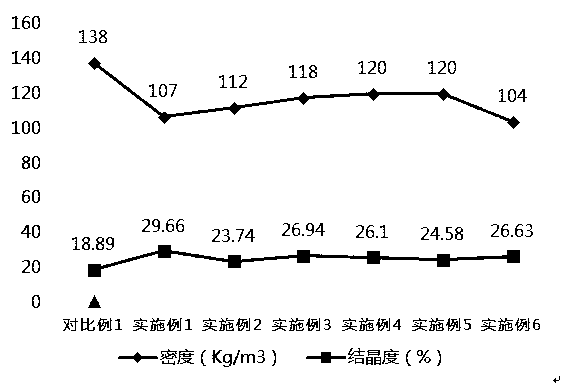

A technology of thermoplastic polyester and plasticity, which is applied in the field of foamed polyester, can solve problems such as limiting application and affecting foam performance, and achieves the effects of stable foaming process, uniform cells, and improved process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 100 parts by weight of PET, place it in a blast or vacuum oven, and bake it at 160°C for more than 4 hours to ensure that the moisture content is lower than 200ppm. Then mix it evenly with 1 part of attapulgite (Changzhou Dingbang Mineral Products, particle size 5um), 1 part of chain extender (1,3PBO, PMDA mixture), 0.8 part of antioxidant 1010, and add it to the serial two-stage screw extruder , the extrusion temperature from the conveying section to the homogenizing section is: 100°C, 100°C, 220°C, 248°C, 253°C, 258°C, 258°C, 258°C, 258°C, 258°C, 255°C. The temperature is 255°C, the screw speed is set to 70RPM, and the amount of foaming gas injected is 0.8kg / h. The driving force of the internal and external pressure difference formed by the rapid pressure relief of the die forms the bubble nucleus hot spot and the foam grows and forms, and then the rapid cooling and shaping part , traction part, cutting part and winding and stacking part to obtain thermoplastic ...

Embodiment 2

[0039] Weigh 100 parts by weight of PET, place it in a blast or vacuum oven, and bake it at 160°C for more than 4 hours to ensure that the moisture content is lower than 200ppm. Then mix evenly with 1 part of sepiolite (Tuoyi new material, particle size 5um), 1 part of chain extender (1,3PBO, PMDA mixture), 0.8 part of antioxidant 1010, and add it to the serial two-stage screw extruder , the extrusion temperature from the conveying section to the homogenizing section is: 100°C, 100°C, 220°C, 248°C, 253°C, 258°C, 258°C, 258°C, 258°C, 258°C, 255°C. The temperature is 255°C, the screw speed is set to 70RPM, and the amount of foaming gas injected is 0.8kg / h. The driving force of the internal and external pressure difference formed by the rapid pressure relief of the die forms the bubble nucleus hot spot and the foam grows and forms, and then the rapid cooling and shaping part , traction part, cutting part and winding and stacking part to obtain thermoplastic polyester foam materia...

Embodiment 3

[0043] Weigh 100 parts by weight of PET, place it in a blast or vacuum oven, and bake it at 160°C for more than 4 hours to ensure that the moisture content is lower than 200ppm. Then mix evenly with 1 part of wollastonite powder (Jingcheng Chemical Industry, particle size 5um), 1 part of chain extender (1,3PBO, PMDA mixture), 0.8 part of antioxidant 1010, and add to the serial two-stage screw extruder Among them, the extrusion temperature from the conveying section to the homogenizing section is: 100°C, 100°C, 220°C, 248°C, 253°C, 258°C, 258°C, 258°C, 258°C, 258°C, 255°C. The temperature is 255°C, the screw speed is set to 70RPM, and the amount of foaming gas injected is 0.8kg / h. The driving force of the internal and external pressure difference formed by the rapid pressure relief of the die forms the bubble nucleus hot spot and the foam grows and forms, and then undergoes rapid cooling and shaping Part, traction part, cutting part and winding and stacking part to get thermopl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com