Modified PVC wallboard and preparation method thereof

A PVC resin and modification technology, applied in the field of building materials, can solve problems such as fracture, insufficient strength, limited use range, etc., and achieve the effects of excellent tensile properties, increased thickness, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

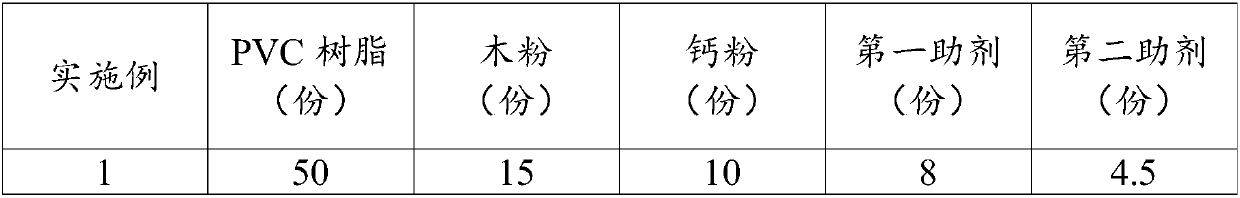

Embodiment 1-9

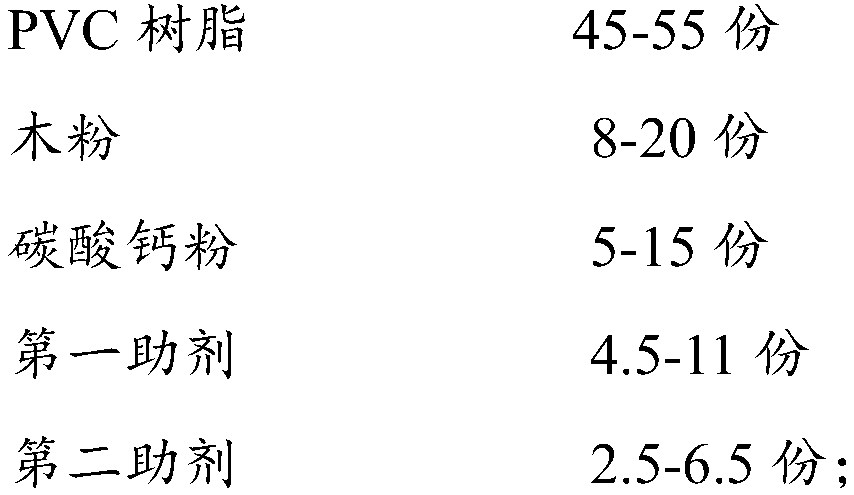

[0034] The raw material ratio is as follows:

[0035]

[0036]

[0037] Wherein the second auxiliary agent is mixed with a modified AC foaming agent and sodium bicarbonate with a mass ratio of 2:1, and the raw material mass ratio of the modified AC foaming agent is as follows:

[0038]

[0039] Wherein the raw material mass ratio of the first auxiliary agent is as follows:

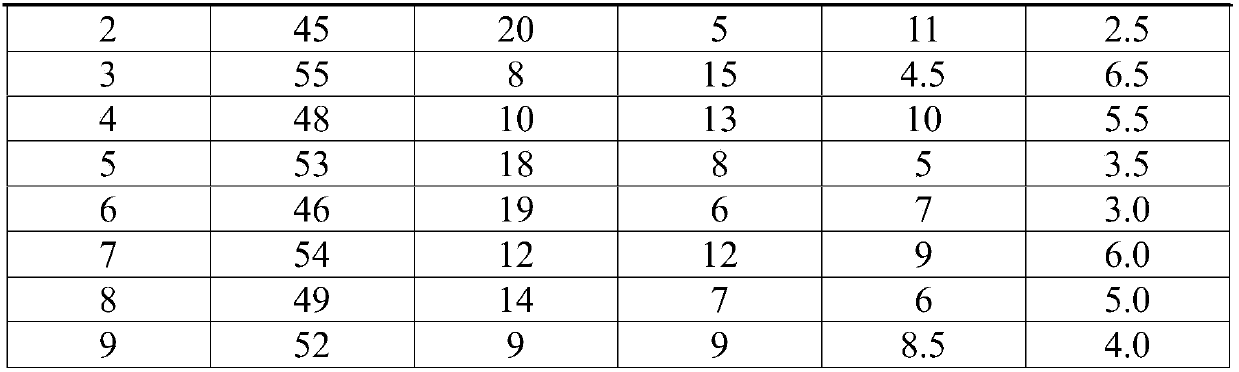

[0040] Example

Foaming aid

1

10

15

2

2

9

17

2

3

9

18

1

4

10

16

2

5

10

17

2

6

9

15

2

7

9

16

1

8

10

18

2

9

10

19

1

[0041] The preparation method of above-mentioned AC modified wallboard, comprises the steps:

[0042] Mixing and granulation: pre-treat the wood powder and the calcium powder, then mix with the PVC resin and the first auxiliary agent in a mixer for 2-3 hours, cool to 35-45°C, add The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com