Power battery cooling system, control method and vehicle

A battery system and power battery technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of high energy consumption, high battery temperature, and reduced efficiency of the vehicle, so as to improve the driving experience, increase the cruising range, and avoid The effect of repeated start and stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

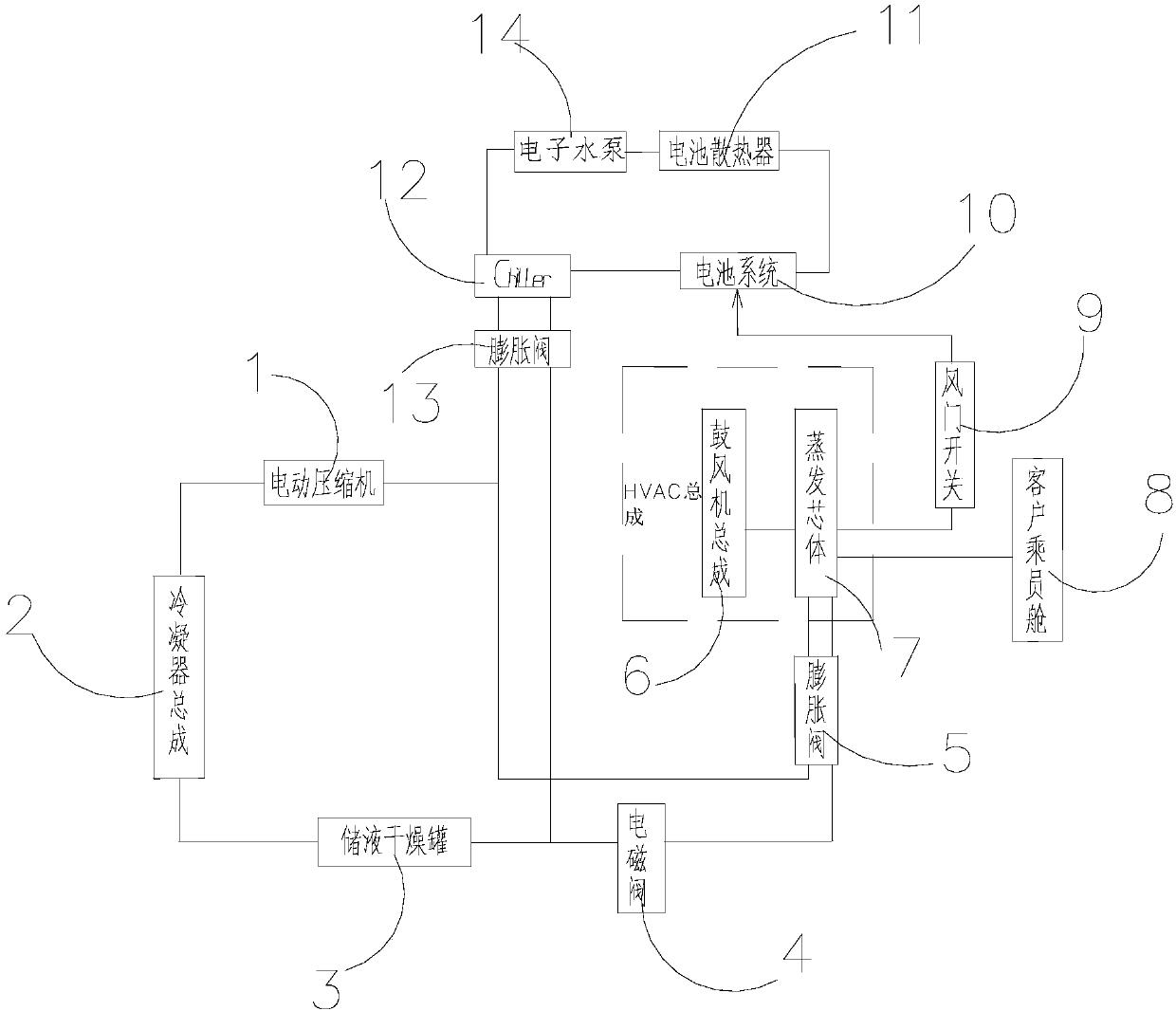

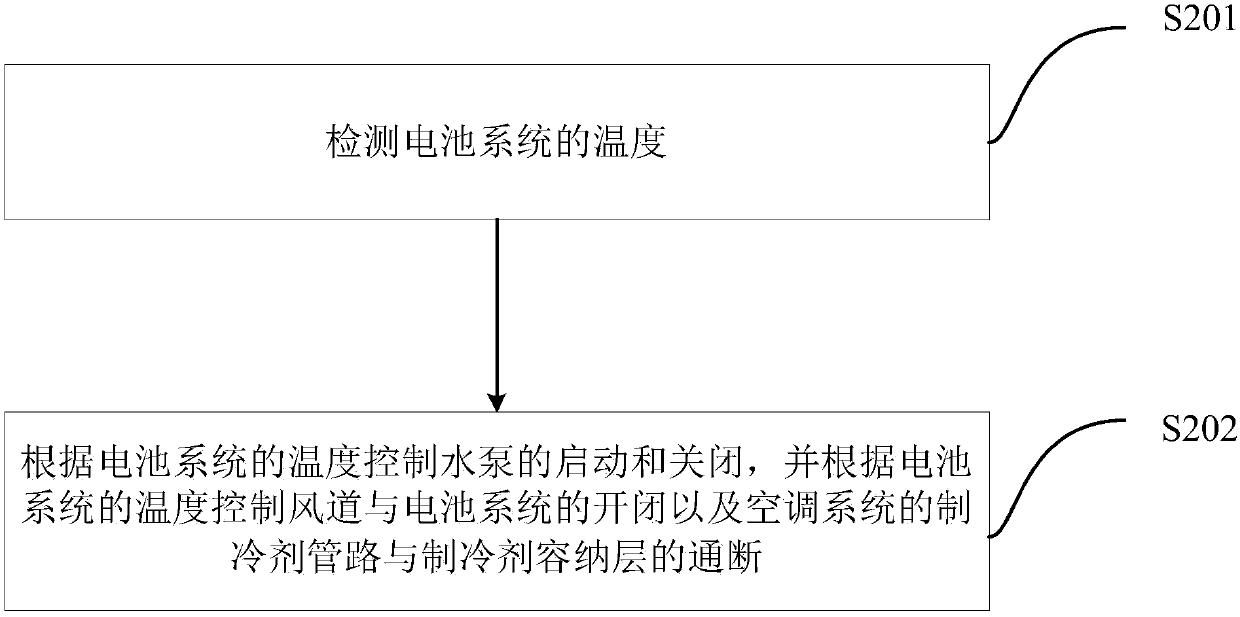

[0030] figure 1 It is a cooling system for a power battery according to an embodiment of the present invention. Such as figure 1 As shown, the power battery cooling system according to an embodiment of the present invention includes: a battery cooling system and an air conditioning system.

[0031] Such as figure 1 As shown, the battery heat dissipation system includes a battery system 10, a coolant cooler 12, a water pump 14, and a battery radiator 11 connected in sequence through a coolant pipeline, wherein the coolant pipeline is filled with coolant, and the coolant cooler 12 It has a cooling liquid storage layer and a refrigerant storage layer, the cooling liquid storage layer is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com