Food processor with good heat dissipating effect

A technology for food processors and heat dissipation effects, which is applied in the direction of electromechanical devices, casings/covers/supports, electric components, etc., can solve problems such as unsatisfactory heat dissipation effects of motors, increased motor costs, and impact on motor life, so as to achieve easy molding , the air inlet area is reduced, and the processing cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

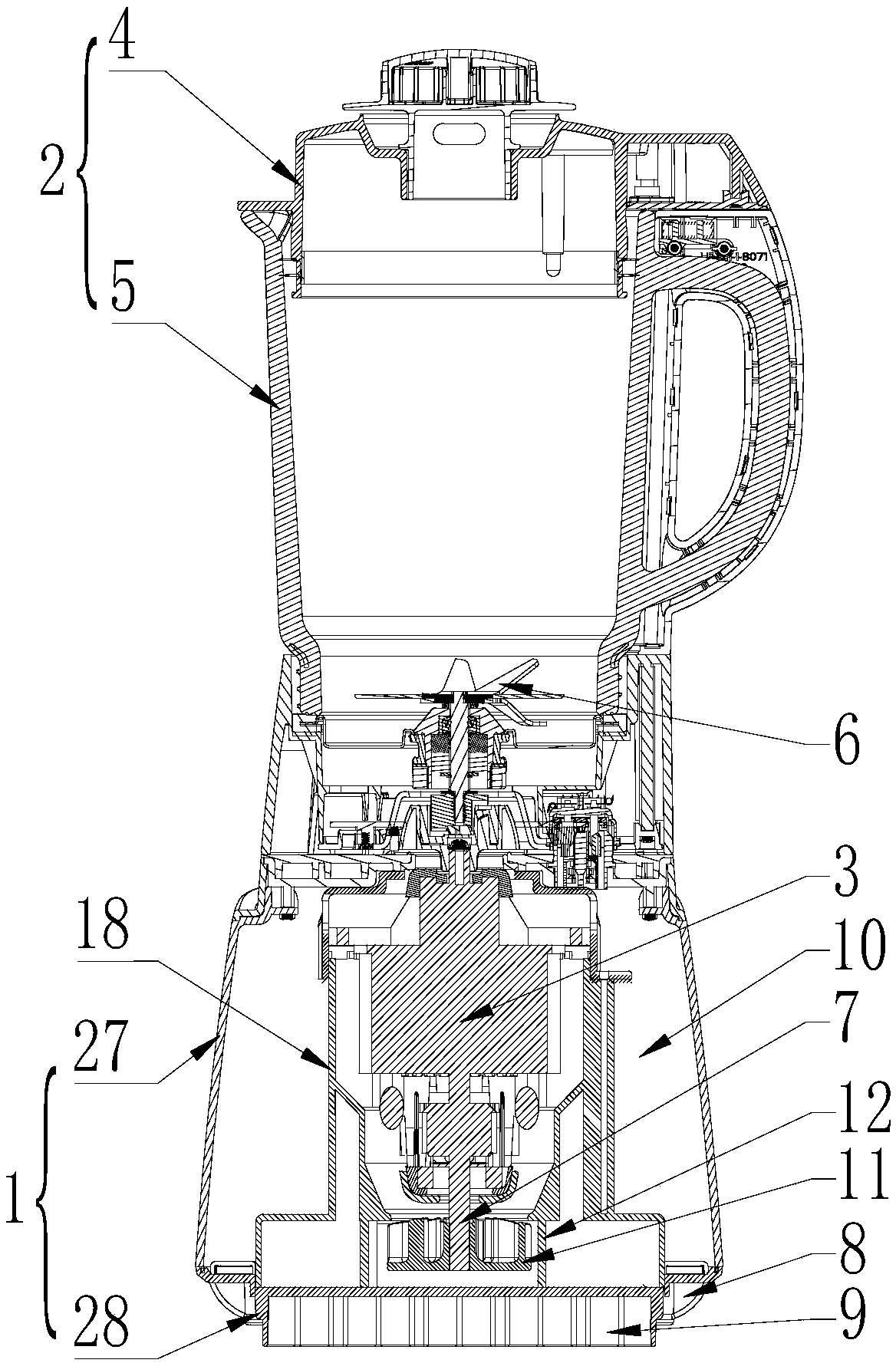

[0039] Such as figure 1 and figure 2 As shown, the food processor of this embodiment includes a machine base 1 and a stirring cup 2, a motor 3 and a circuit board (not shown in the figure) are arranged in the machine base 1, the stirring cup 2 is arranged above the machine base 1, and the stirring cup 2 includes a cup cover 4 and a cup body 5, the cup body 5 is a glass cup with a handle, the cup cover 4 and the cup body 5 are surrounded to form a crushing space, the cup body 5 is provided with a crushing knife 6, and the upper end of the motor shaft 7 of the motor 3 It is connected with the crushing knife 6, and the two are connected by a coupling. The coupling includes an upper coupling (not shown in the figure) and a lower coupling (not shown in the figure), and the upper coupling and the crushing knife 6 is connected to the cutter shaft, and the lower coupling is connected to the upper end of the motor shaft 7. When the stirring cup 2 is placed on the base 1, the upper co...

Embodiment 2

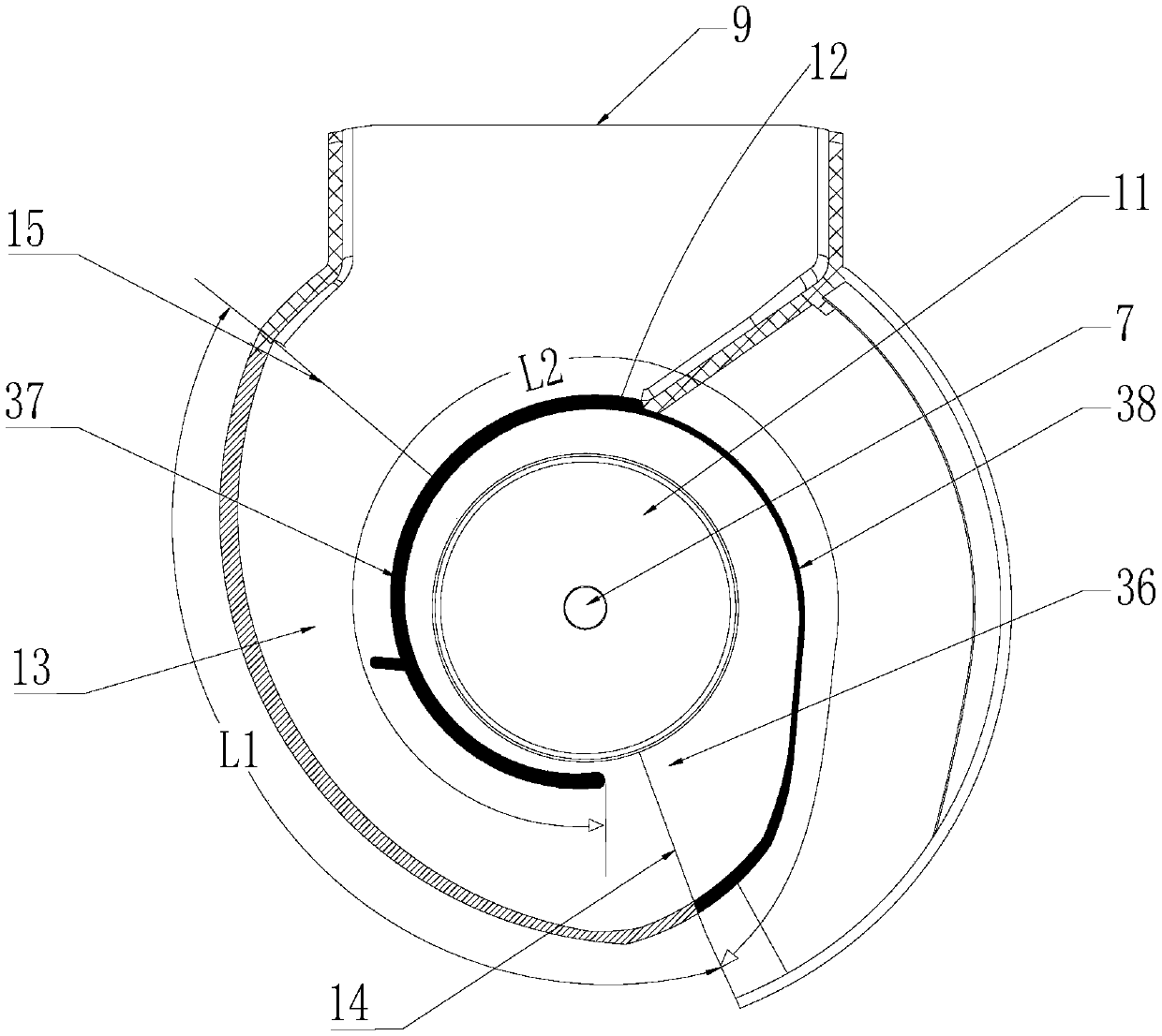

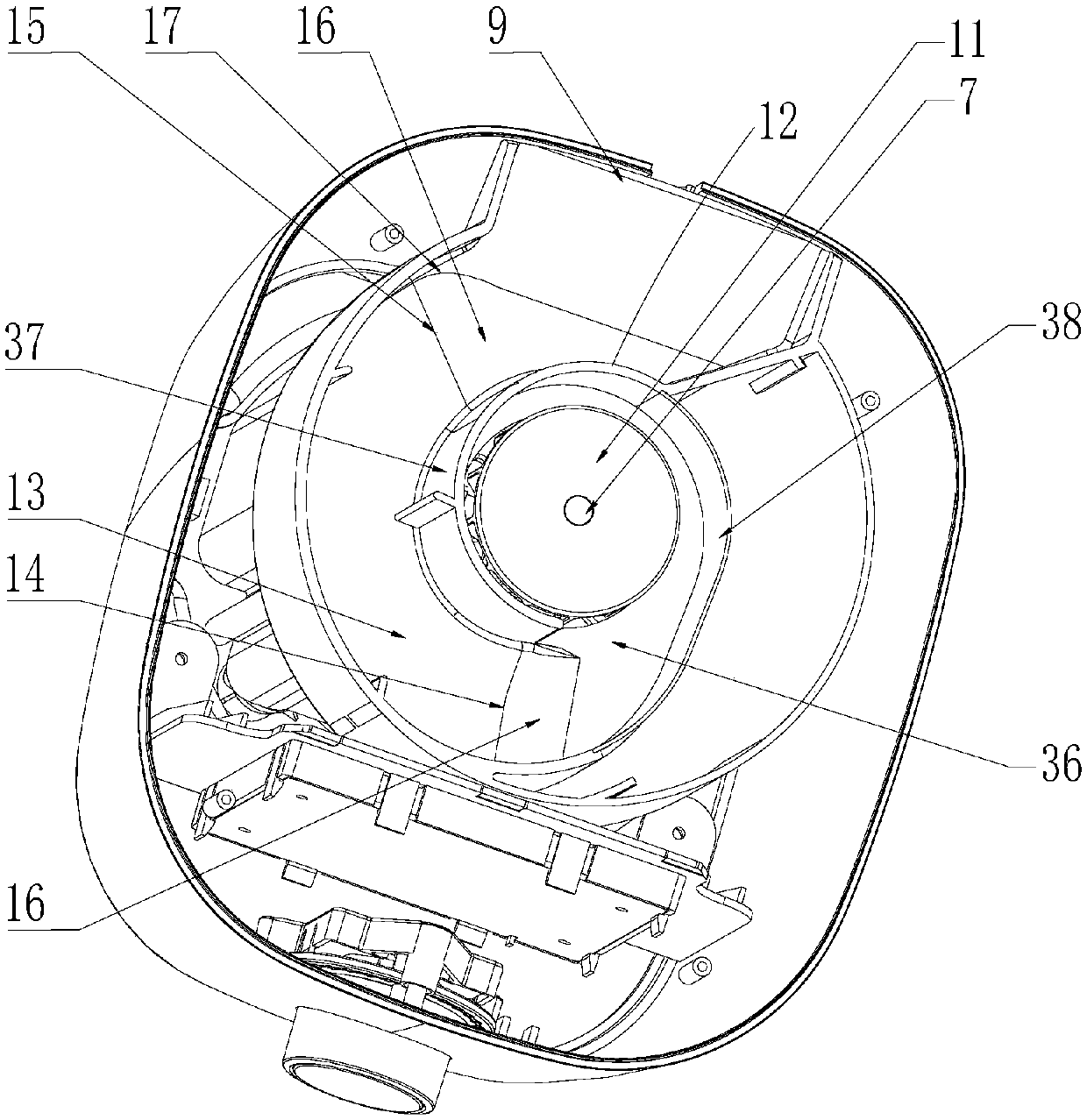

[0045] The difference between this embodiment and Embodiment 1 is that the circulation bend is a variable cross-section bend, combined with image 3 and Figure 4 As shown, the circulation bend 13 is a variable cross-section bend, which can weaken the acoustic reactance to eliminate noise, and can weaken the sound intensity of the noise. The sound intensity is a kind of noise energy parameter, which is beneficial to noise reduction and becomes The cross-section curve is also conducive to the continuous reflection of noise in the curve, so as to strengthen the mutual interference of noise, which is more conducive to weakening the noise and improving the user experience. The radial section of the circulation curve 13 is from the first connecting end 14 to the second connecting end 15 undergoes a change from small to large and then from large to small, the radial cross-sectional size at the first connecting end 14 is equal to and the smallest at the radial cross-sectional size at...

Embodiment 3

[0053] The difference between this embodiment and Embodiment 1 and Embodiment 2 lies in the structure of the motor barrel 18: combining Figure 5 to Figure 7 As shown, the motor barrel 18 includes a barrel body 19, a barrel seat 20 at the bottom of the barrel body 19, and a barrel cover 21 at the top of the barrel body 19. The barrel cover 21 is provided with a first shaft hole 22 through which the upper end of the power supply shaft 7 passes. The upper end of the motor shaft 7 passes through the first shaft hole 22 and is connected with the pulverizer 6. In this embodiment, the no-load speed of the motor 3 is 30000r / min. Located under the cylinder cover 21, the cylinder cover 21 and the motor bracket are fixed on the top of the cylinder body 19 by fasteners. The cylinder seat 20 is arranged on the machine base 1 and communicates with the air outlet 9, and the two are communicated through the volute 12. The upper part of the motor barrel 18 is provided with a communication por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com