Steam recycling system of acrylic fiber spinning production setting device and control method

A technology of setting device and recovery system, applied in the field of acrylic fiber spinning, can solve the problems of heat waste, pollution, thermal pollution of chemical reagents, etc., and achieve the effects of ensuring quality, maintaining factory environment, and reducing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

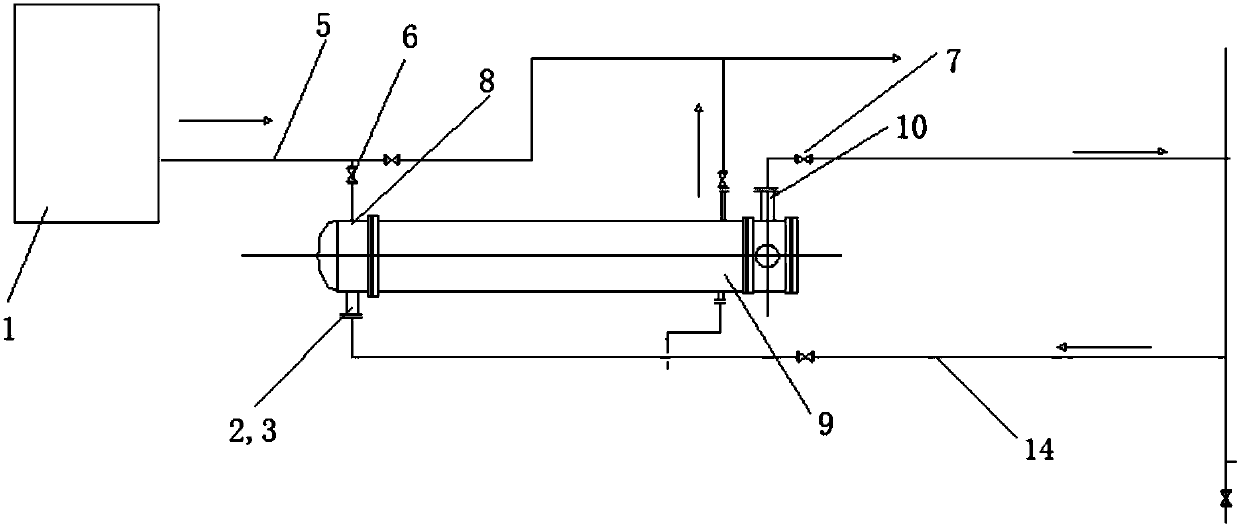

[0038] Such as figure 1 As shown, the steam recovery system of this embodiment includes a sizing device 1 and a condensing recovery device 2 connected to the sizing device. The condensing recovery device 2 includes a heat exchange device 3. The heat exchange device 3 has a condensing medium circulation pipeline. The sizing device 1 The steam in the steam enters the heat exchange device 3, exchanges heat with the condensing medium in the condensing medium circulation pipeline, and is completely condensed and recovered within T time.

[0039] The heat exchange device 3 can communicate with the sizing device 1 through pipelines, and the condensing medium pipeline of the heat exchange device 3 is isolated from the passage through which the steam in the heat exchange device 3 passes and performs heat exchange. The condensing medium in the condensing medium pipeline can be water at normal temperature, water cooled to a certain temperature, or other gas or liquid medium, which can pe...

Embodiment 2

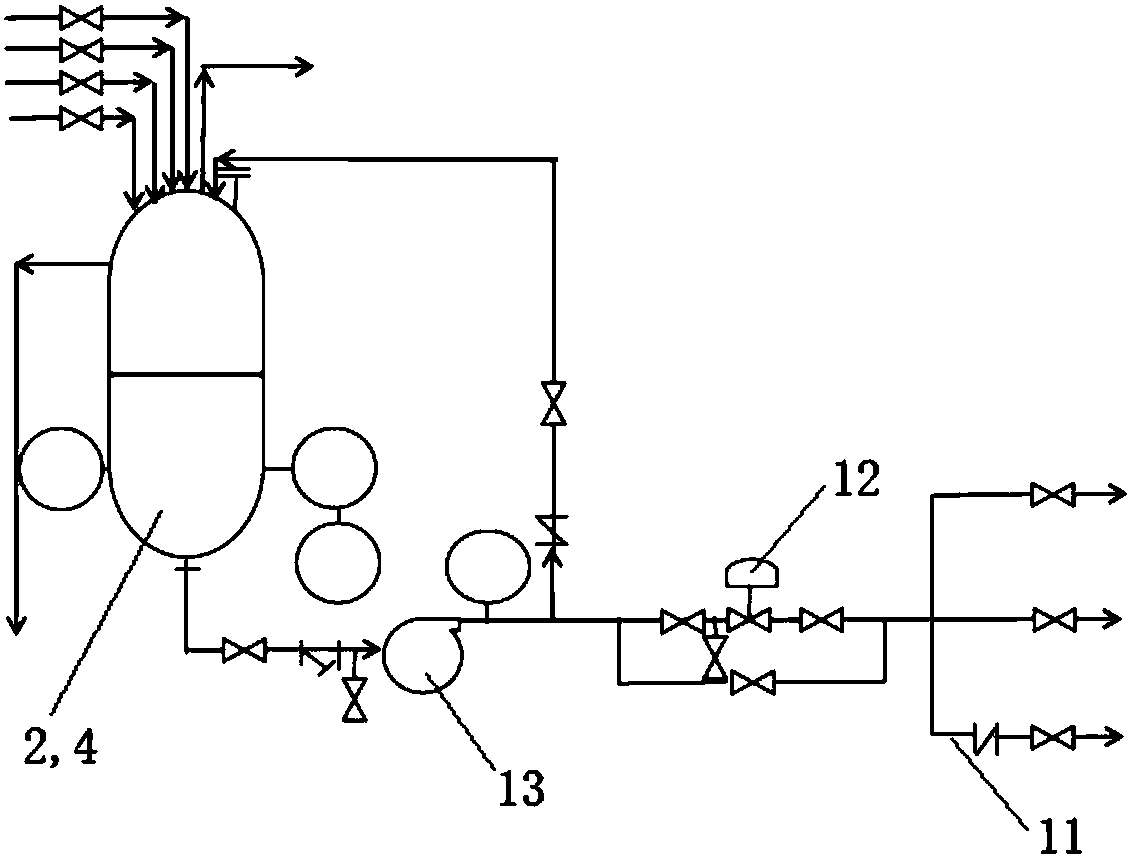

[0054] Such as figure 2 As shown, this embodiment is a further limitation of Embodiment 1. The steam recovery system of this embodiment includes a sizing device 1 and a condensation recovery device 2 connected to the sizing device. The steam discharged by the sizing device 1 in a certain period of time All condensate recovery in the condensate recovery device 2.

[0055] The condensation recovery device 2 not only includes a heat exchange device 3, but also includes a storage device. The storage device communicates with the heat exchange device 3 through a pipeline, and the steam in the setting device 1 enters the heat exchange device 3 to condense to a liquid at a temperature of T, and collects into the storage device through the pipeline.

[0056] A plurality of sizing devices 1 are set in the factory area, and each sizing device 1 is provided with a corresponding heat exchange device 3 . The outlet of the exhaust pipeline 5 of each sizing device 1 is connected with the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com