Coffee bean drying total heat recycling equipment

A technology of total heat recovery and coffee beans, which is applied in heat recovery systems, lighting and heating equipment, drying gas layout, etc., can solve the problems of low drying heat efficiency and lower coffee quality, and achieve the goal of avoiding secondary fermentation and efficient utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

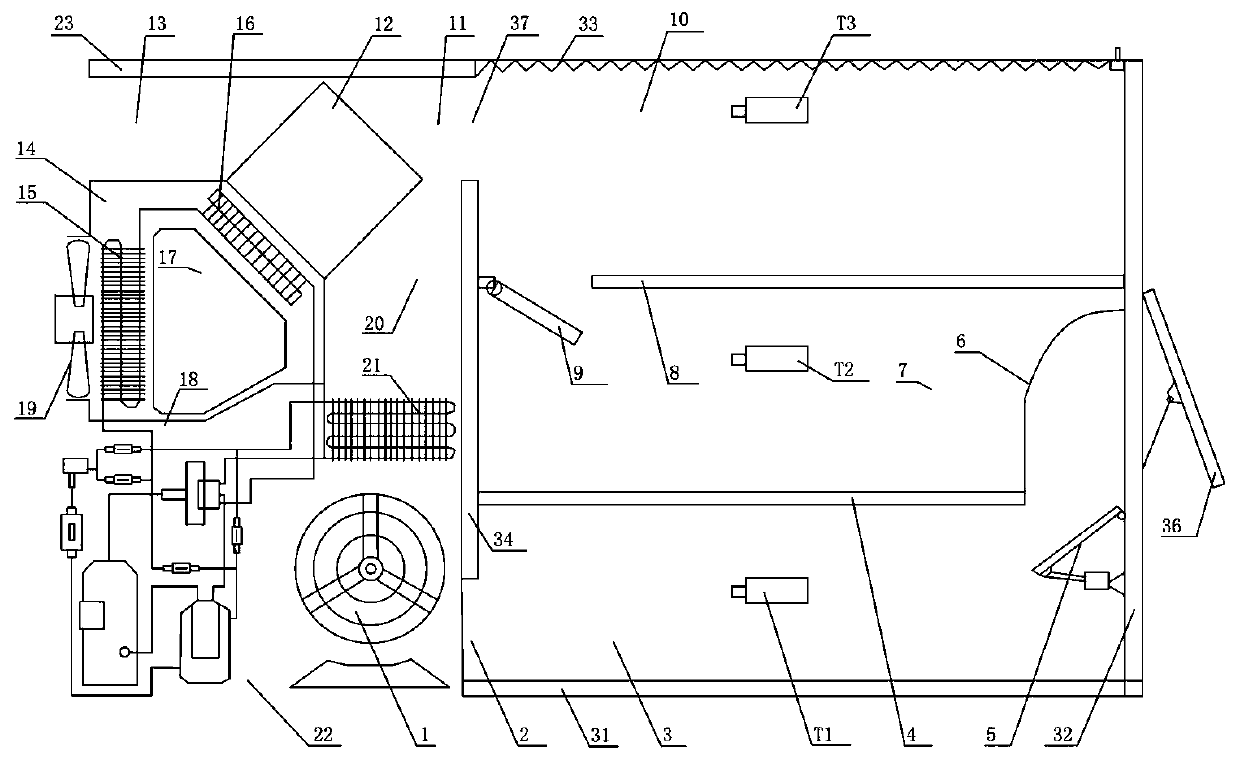

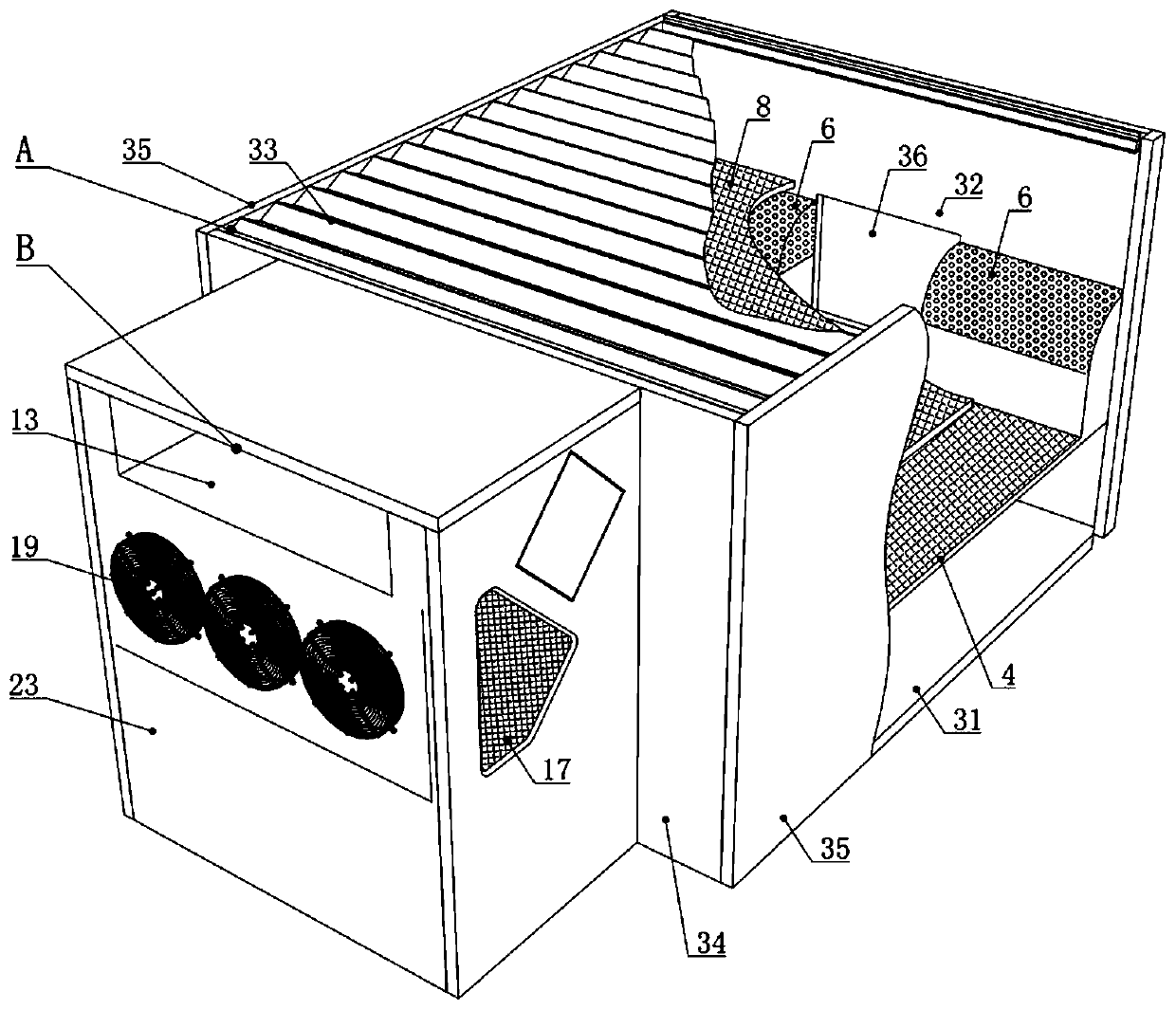

[0014] A device for controlling the fermentation of coffee wet beans, comprising a drying room A, the drying room A is composed of a front wall 34, a rear wall 32, a side wall 35, an insulating floor 31 and a ceiling 33; the upper end of the front wall 34 is provided with row Wet port 37, the lower end of the front wall 34 is provided with a drying room air inlet 2; the rear wall 32 is provided with a discharge door 36;

[0015] The interior of the drying room A is divided into a surface drying chamber 10, an integral drying chamber 7 and a hot air buffer chamber 3 by an upper screen 8 and a lower screen 4, and the lower screen 4 is close to the rear wall 32. One end is provided with an air guide pipe 6, and one end of the air guide pipe 6 close to the hot air buffer chamber 3 is provided with an air guide door 5, and the air guide pipe 6 communicates with the hot air drying chamber 3 and the integral drying chamber 7;

[0016] One end of the upper screen 8 near the front wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com