Infrared-visible light image up-conversion device based on semiconductor quantum dots and liquid crystal, and imaging method

An infrared image and visible light technology, applied in the direction of instruments, optics, measuring devices, etc., can solve the problems that photodetection devices and photoelectric display devices cannot be integrated on the same substrate, and the structure and preparation process are not compatible, so as to achieve low preparation cost, Enhanced photodetection sensitivity and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

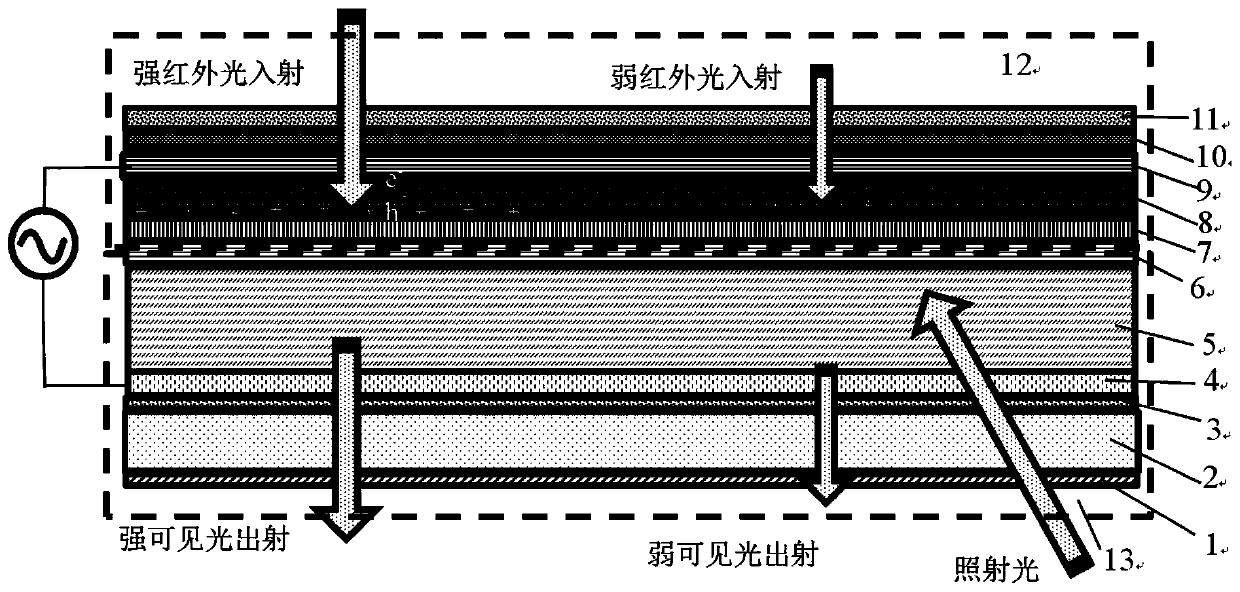

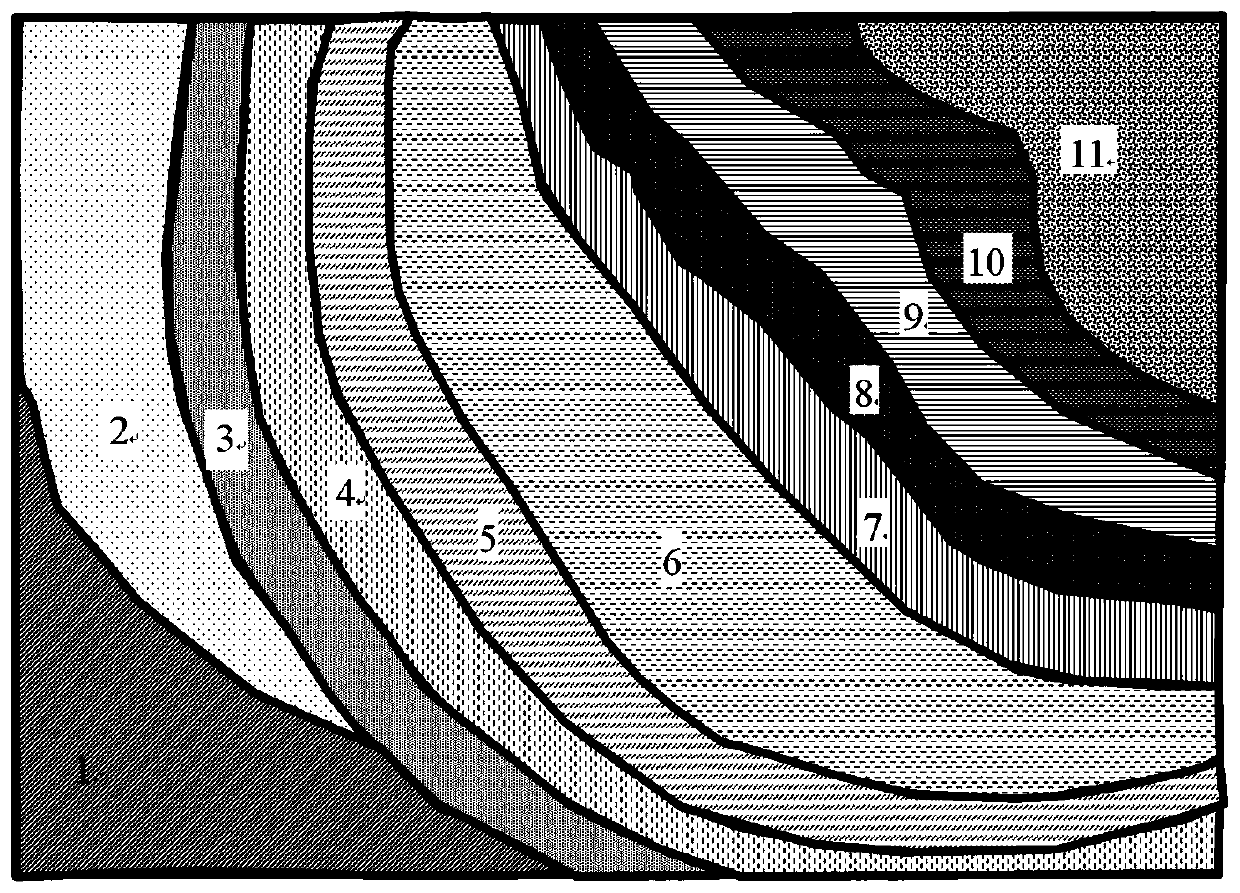

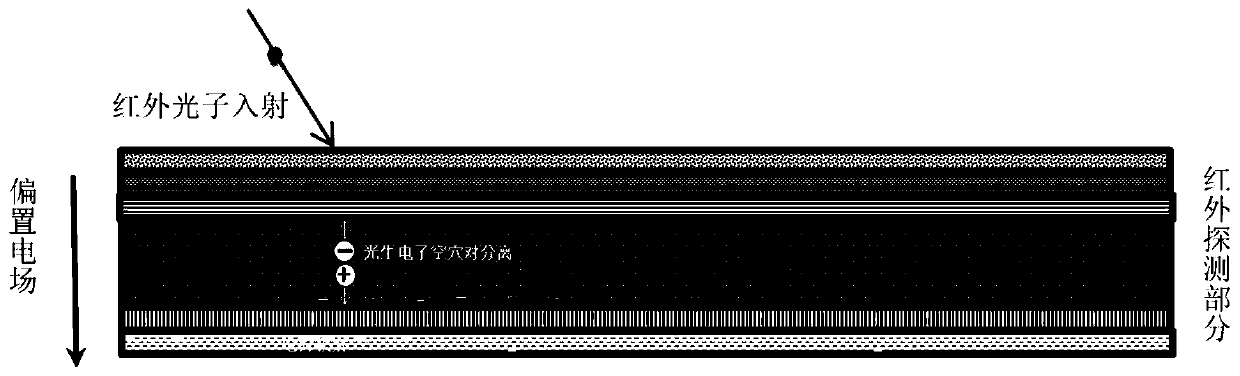

[0026] Such as figure 1 and figure 2 As shown, the infrared-visible light image up-conversion device based on semiconductor quantum dots and liquid crystals of the present invention includes an upper substrate 11, a visible light shielding layer 10, an infrared transparent electrode 9, a semiconductor quantum dot photoelectric active layer 8, and a visible light from top to bottom. Reflective layer 7 , liquid crystal upper alignment layer 6 , liquid crystal layer 5 , liquid crystal lower alignment layer 4 , visible light transparent electrode 3 , lower substrate 2 and polarizer 1 . Among them, 1-6 constitute the visible light image display component 13, which is the visible light image display part based on liquid crystal; 6-11 constitute the infrared image detection component 12, which is the infrared image detection part b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com