Acoustic levitation device and method in liquid environment

A technology of liquid environment and acoustic levitation, which is applied in the direction of sound producing equipment, educational equipment, instruments, etc., and can solve the problems of electromagnetic strength, biological health damage, and high requirements for electromagnetic levitation materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described below with reference to specific examples. Those skilled in the art can understand that these examples are only used to illustrate the present invention and do not limit the scope of the present invention in any way.

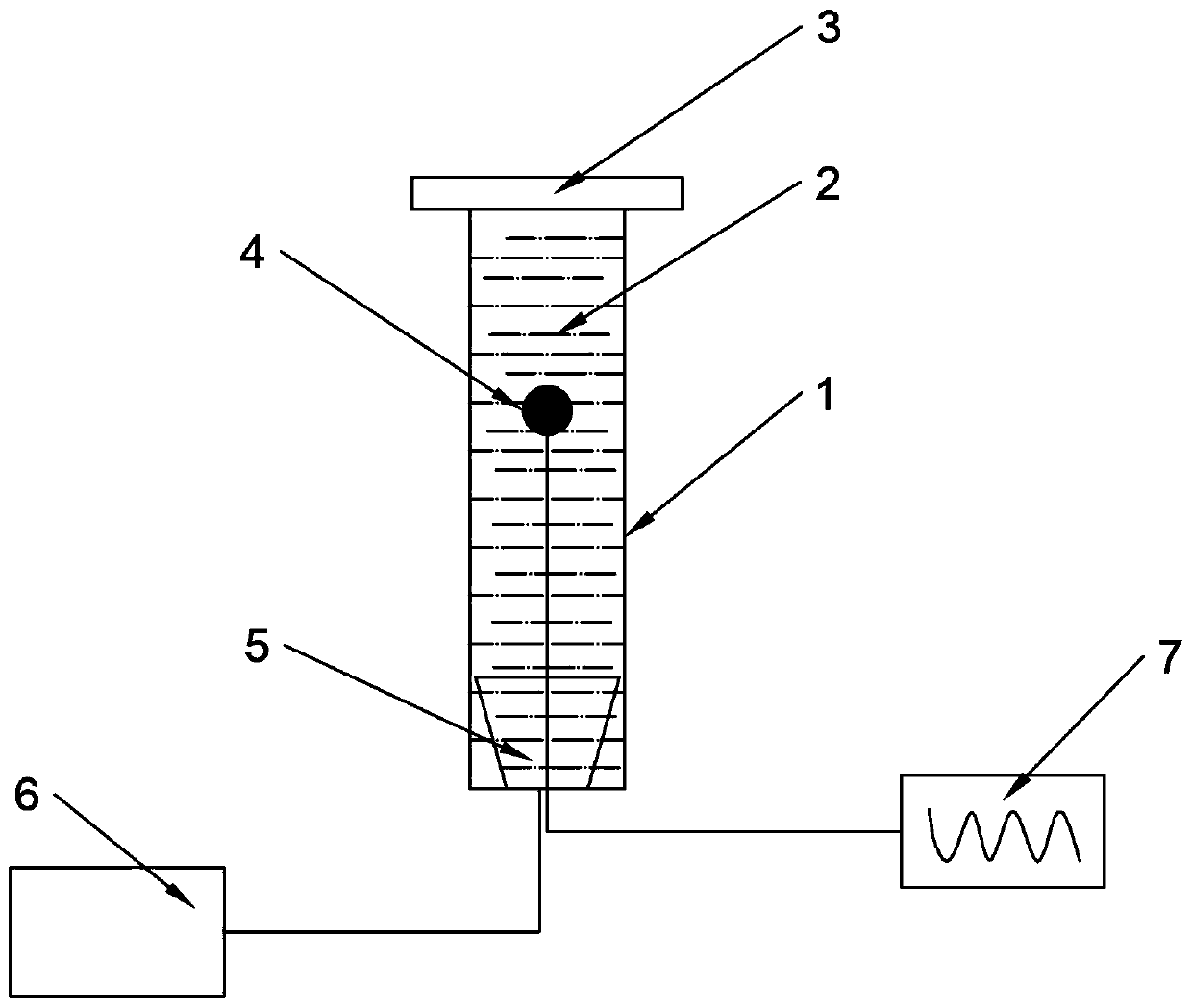

[0021] An acoustic levitation device in a liquid environment, see figure 1 , including a waveguide tube 1, a hydrophone 4, a transducer 5 for emitting sound waves, a signal generator 6 and an oscilloscope 7; the waveguide tube 1 is a cylindrical barrel with one end open, and the opening is sealed by a steel plate , the inside of the waveguide tube 1 is filled with a liquid medium 2; the transducer 5 is placed at the bottom of the waveguide tube 1, the transducer 5 is a piston transducer, and is electrically connected to the signal generator 6 outside the waveguide tube 1, The hydrophone 4 is suspended in the liquid medium 2 and connected to the oscilloscope 7 outside the waveguide tube 1 .

[0022] Specifically, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com