Preparation method and application of boric acid functionalized graphene material with targeted photo-thermal sterilization performance

A carboxylated graphene and photothermal technology, which is applied to medical preparations with no active ingredients, medical preparations containing active ingredients, wave energy or particle radiation treatment materials, etc., can solve the secondary damage of surrounding normal tissues, photothermal The agent has no targeting ability to bacteria and cannot be killed by heating, so as to achieve the effect of less toxic and side effects, realize targeted killing, and treat skin infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

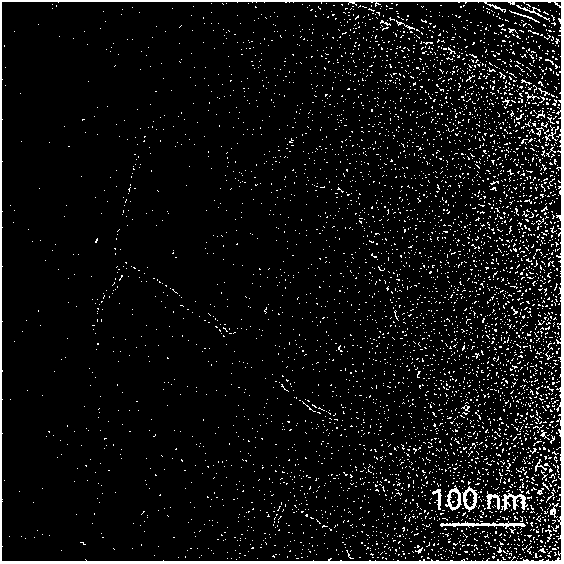

[0036] Embodiment one: a kind of preparation method of the boric acid functionalized graphene material with targeted photothermal sterilization performance, it comprises the following steps:

[0037] Step 1: uniformly mix 2mg carboxylated graphene, 0.6mg EDC, 0.6mg NHS and 10mL deionized water, and stir at room temperature for 4 hours to obtain a mixed solution;

[0038] Step 2: 2 mg of 3-aminopyridine was added to the mixture, and stirred at room temperature for 24 hours to obtain suspension A;

[0039] Step 3: Centrifuge the suspension A at a speed of 11,000 rpm for 90 minutes, then repeatedly wash the product 3 times with deionized water to remove impurities;

[0040] Step 4: Resuspend the product obtained in Step 3 with 10 mL of DMF to obtain a suspension B, add 2 mg of 3-bromomethylphenylboronic acid to the suspension B, and stir for 12 hours in an oil bath at a temperature of 50°C , to obtain suspension C;

[0041] Step 5: Centrifuge the suspension C at a speed of 13,0...

Embodiment 2

[0042]Embodiment two: a kind of preparation method of the boric acid functionalized graphene material with targeted photothermal sterilization performance, it comprises the following steps:

[0043] Step 1: uniformly mix 2mg carboxylated graphene, 0.6mg EDC, 0.6mg NHS and 10mL deionized water, and stir at room temperature for 8 hours to obtain a mixed solution;

[0044] Step 2: 2 mg of 3-aminopyridine was added to the mixture, and stirred at room temperature for 24 hours to obtain suspension A;

[0045] Step 3: Centrifuge the suspension A at a speed of 11,000 rpm for 90 minutes, then repeatedly wash the product 3 times with deionized water to remove impurities;

[0046] Step 4: Resuspend the product obtained in Step 3 with 10 mL of DMF to obtain a suspension B, add 2 mg of 3-bromomethylphenylboronic acid to the suspension B, and stir for 6 hours in an oil bath at a temperature of 50°C , to obtain suspension C;

[0047] Step 5: Centrifuge the suspension C at a speed of 13,000...

Embodiment 3

[0048] Embodiment three: a kind of preparation method of the boric acid functionalized graphene material with targeted photothermal sterilization performance, it comprises the following steps:

[0049] Step 1: uniformly mix 2mg carboxylated graphene, 0.6mg EDC, 0.6mg NHS and 10mL deionized water, and stir at room temperature for 4 hours to obtain a mixed solution;

[0050] Step 2: 2 mg of 3-aminopyridine was added to the mixture, and stirred at room temperature for 24 hours to obtain suspension A;

[0051] Step 3: Centrifuge the suspension A at a speed of 11,000 rpm for 90 minutes, then repeatedly wash the product 3 times with deionized water to remove impurities;

[0052] Step 4: Resuspend the product obtained in Step 3 with 10 mL of DMF to obtain a suspension B, add 2 mg of 3-bromomethylphenylboronic acid to the suspension B, and stir for 12 hours in an oil bath at a temperature of 90°C , to obtain suspension C;

[0053] Step 5: Centrifuge the suspension C at a speed of 13...

PUM

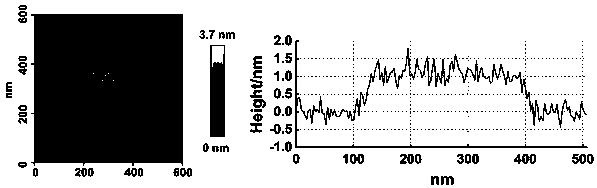

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com