Device and method for circularly separating soil microplastics based on sodium bromide solution

A technology of solution circulation and sodium bromide, which is applied in the field of separation, can solve the problems of difficult separation of high-density microplastics, long time consumption, and large consumption of reagents, and achieve the effects of reducing wall sticking, reducing procedures, and saving reagents

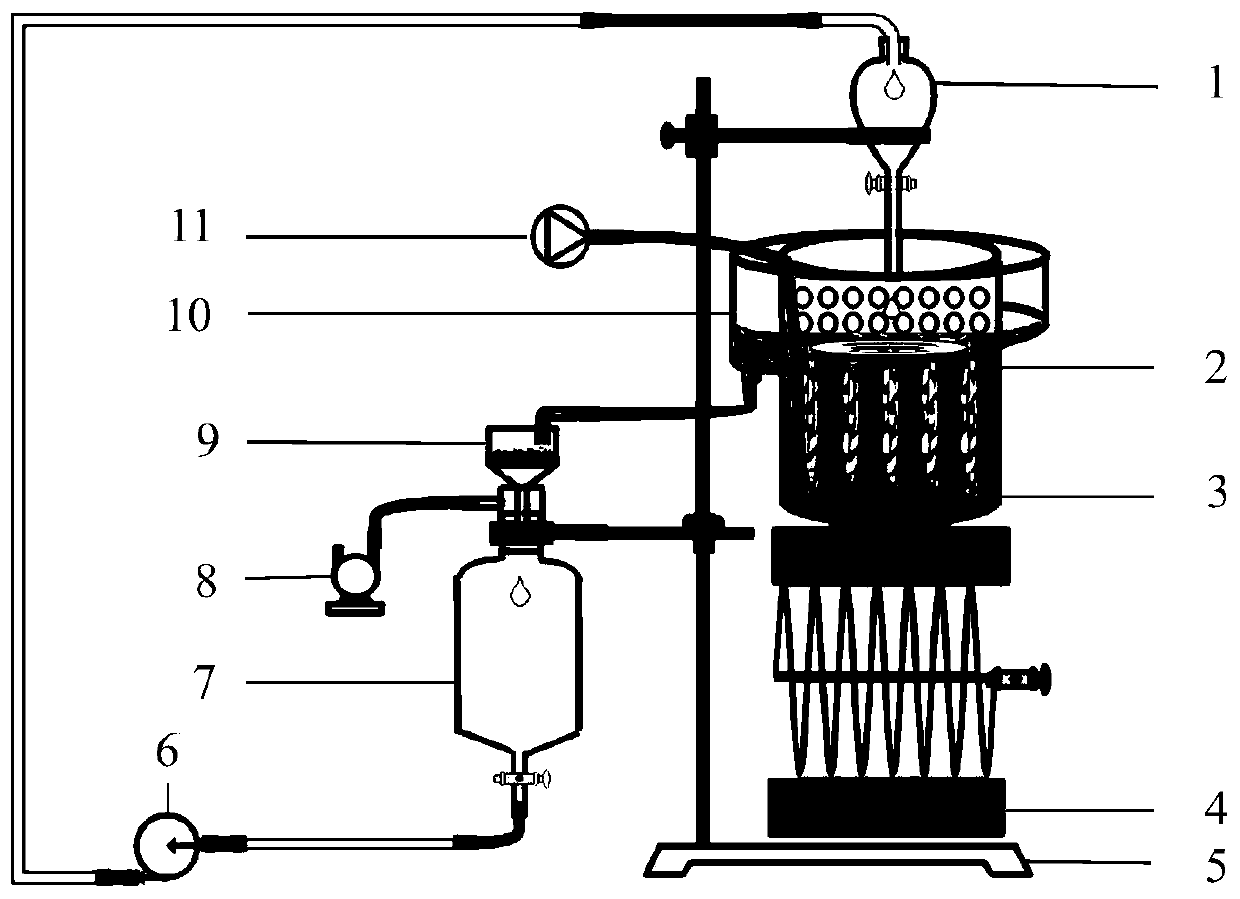

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Taking the separation efficiency of PA, PP, PE, PET, POM, PVC, PC, ABS, PMMA and PS microplastics in soil as an example

[0062] Specific process:

[0063] ① Weigh 50g soil sample (this soil sample is a normal soil sample collected from the campus, without microplastic removal treatment, but the microplastics added in Examples 1-3 are microplastics that have been dyed).

[0064] ②Select 20 granular microplastics (such as PP) of the same type with a size of 1-3mm that have been marked by Nile Red dyeing, and mix them evenly into the soil sample.

[0065] ③ Prepare 200ml saturated sodium bromide solution.

[0066] ④ Pour 100ml of saturated sodium bromide solution into the 2-separator, turn on the aeration device, and then pour the mixed soil sample.

[0067] ⑤ 3-Aeration plate is connected to 11-adjustable aeration pump, aerate for 30 minutes, and then stand for 2 hours.

[0068] ⑥ Put the separator into the soil microplastic separation device, and place a filter membr...

Embodiment 2

[0079] Taking PE as an example, PE granular microplastics with particle sizes of 100-500 μm, 500-1000 μm, and 1000-3000 μm were selected to conduct experiments respectively. The specific process refers to Example 1. The recovery rate of PE microplastics with three particle sizes 83%, 95%, 100%, respectively.

Embodiment 3

[0081] Taking PE as an example, the recovery rate of film-like, fibrous, and granular PE microplastics (500-1000 μm) in soil is studied. The specific process refers to Example 1. The recovery rates of the three shapes of PE microplastics reach 80% respectively. , 83%, 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com