Control testing device of coating ion source

A test device and ion source technology, applied in the field of ion source testing, can solve the problems of reducing the quality of the coating, low stability, electromagnetic interference of the arc source control system, etc., to ensure the quality of work, improve the ability to resist electromagnetic interference, extend The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

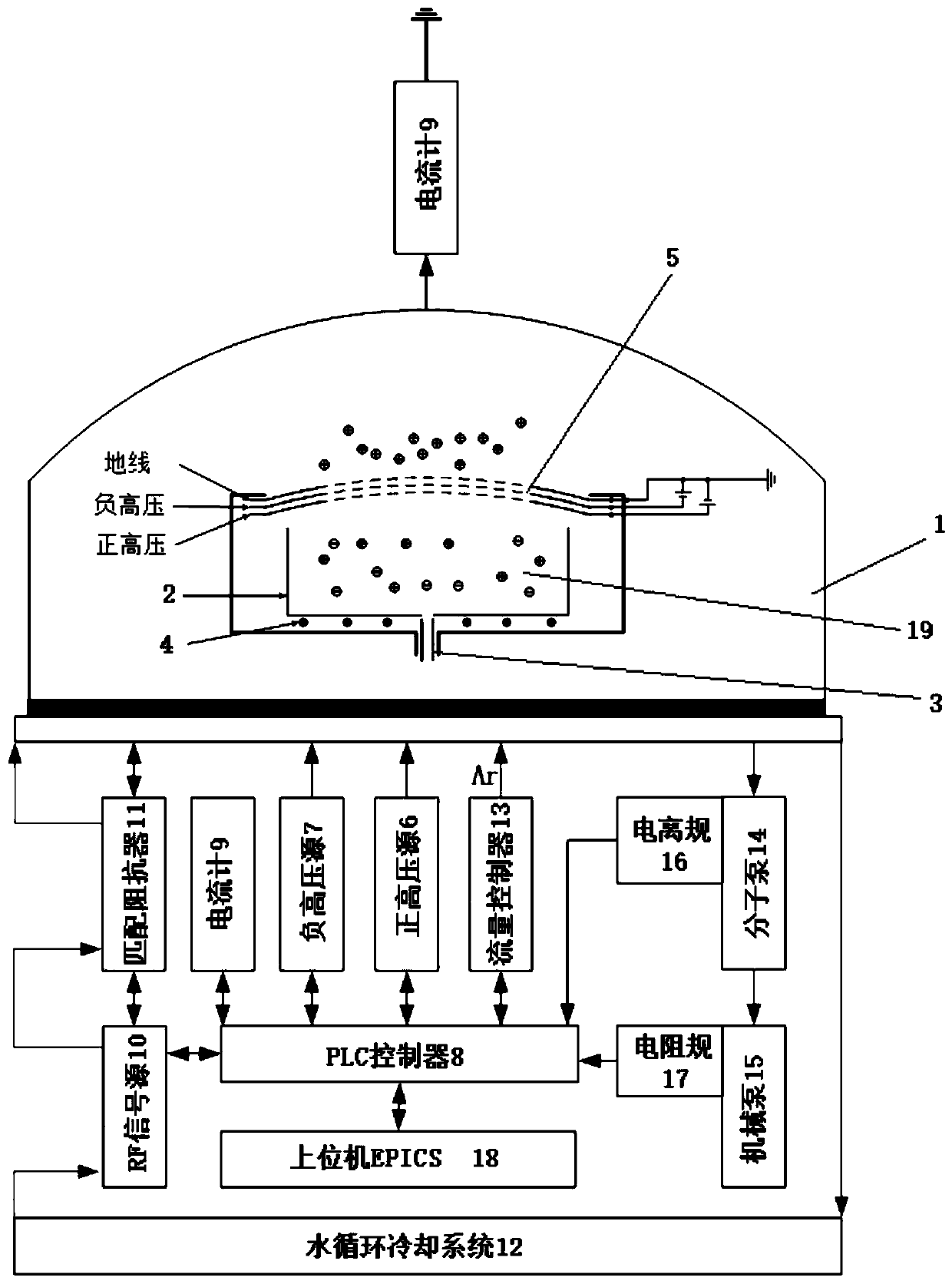

[0028] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0029] The present invention provides a control and test device for a coated ion source. Its working principle is to use a PLC controller with strong anti-interference ability to process data collection and control external hardware equipment, improve the ability to resist electromagnetic interference, and realize the effect of the coating ion source Accurate measurement of the working range to ensure that the coating ion source can meet the production requirements, thereby ensuring the working quality of the coating ion source.

[0030] The present invention will be further described in detail below in conjunction with examples and specific implementations.

[0031] Such as figure 1 As shown, a control and test device for a coated ion source includes a quartz pot 2 arranged in a vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com