Preparation method of static loaded multi-coating yarn or fabric material

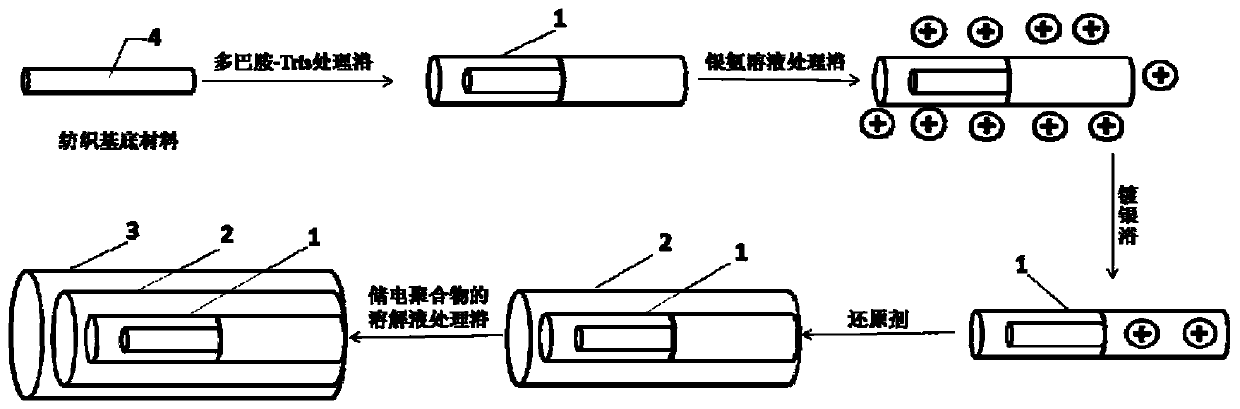

A fabric material and multi-layer coating technology, applied in textiles and papermaking, fiber treatment, fiber type, etc., can solve the problems of small static load, short service life, high rigidity, etc., to increase the ability to load static electricity, enhance Bending resistance and tensile properties, the effect of improving interlayer bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a method for preparing an electrostatically loaded polyester woven fabric material with a bonding layer, a conductive layer and an electrical storage layer. The specific steps are as follows:

[0049] Step 1: Combine layer generation:

[0050] a) Pre-cleaning: wash 300-mesh polyester woven fabric twice in pre-cleaning bath acetone (analytical pure) to remove surface impurities, and then dry naturally at room temperature for 15 minutes;

[0051] b) Preparation of dopamine treatment bath: prepare a buffer solution with a concentration of 10 mM tris-HCl (Tris-HCl), adjust the pH to 8.5; add dopamine hydrochloride and stir to dissolve, and prepare a concentration of 2 g / L dopamine hydrochloride solution treatment bath;

[0052] c) Bonding layer formation: place the pre-cleaned 300-mesh polyester woven fabric in a dopamine hydrochloride solution treatment bath at 30°C with a solid-to-liquid ratio of 1:2, treat it for 30 minutes, wash it in three wat...

Embodiment 2

[0061] This embodiment provides a preparation method of a silver polyester blended woven fabric material with a binding layer, a conductive layer and a storage layer for electrostatic loading, and the specific steps are as follows:

[0062] Step 1: Combine layer generation:

[0063] a) Pre-cleaning: wash the silver polyester blended woven fabric three times in deionized water in the pre-cleaning bath to remove surface impurities, and then dry naturally at room temperature for 10 minutes;

[0064] b) Preparation of dopamine treatment bath: prepare a buffer solution with a concentration of 15mM Tris-HCl, adjust the pH to 8.5; add dopamine hydrochloride and stir to dissolve, and prepare a concentration of 3g / L dopamine hydrochloride solution treatment bath;

[0065] c) Bonding layer generation: place the pre-cleaned silver polyester blended woven fabric in a dopamine hydrochloride solution treatment bath at 40°C with a solid-to-liquid ratio of 1:3, treat for 40 minutes, wash in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com