Metal telluride nanotube and universal preparation method thereof

A metal telluride and nanotube technology, applied in the direction of metal selenide/telluride, binary selenium/telluride compound, nanotechnology, etc., can solve the problem that the energy conversion efficiency of metal telluride cannot meet the application requirements and is not universal and other issues, to achieve safe and pollution-free operation, lower thermal conductivity, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

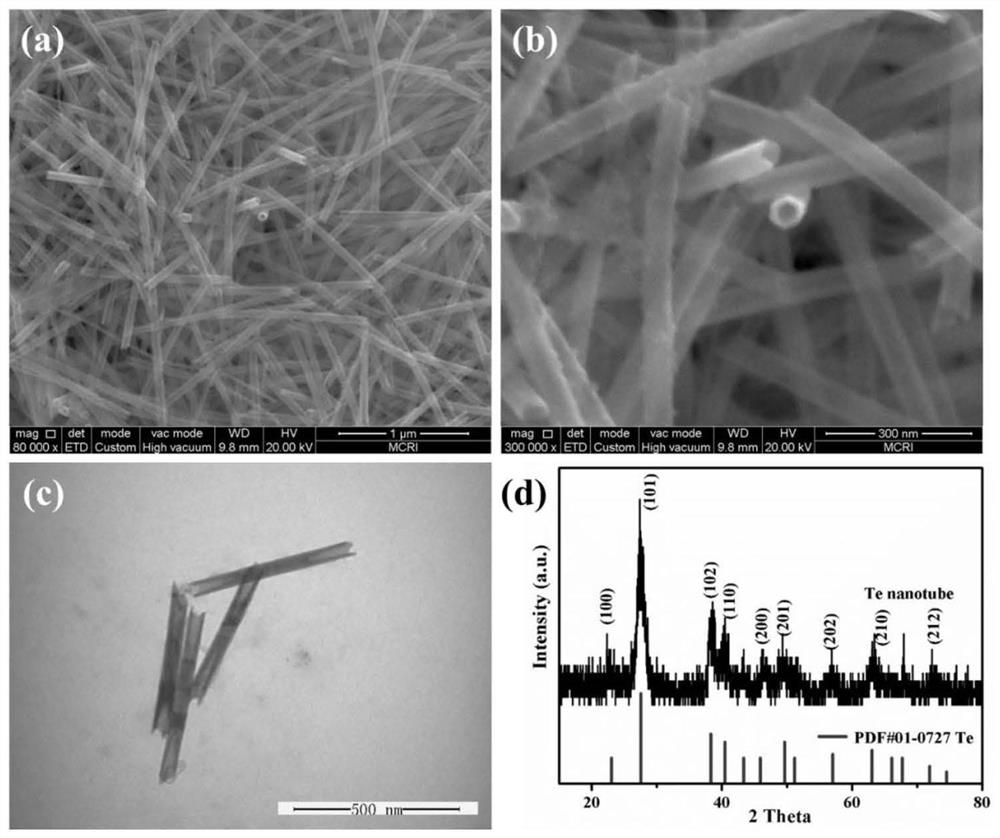

[0042] 0.2394g (1.5mmol) of TeO 2 , 0.5g PVP and 5.6g (10mmol) KOH, mixed and dissolved in 30ml EG at room temperature, fully dissolved into a transparent liquid by magnetic stirring; then poured into a 100ml three-necked bottle, under nitrogen protection, circulating water cooling and Under the condition of magnetic stirring, the mixed solution is heated to 130 DEG C, and the concentration of 0.25ml is rapidly injected into 85% hydrazine hydrate, and the mixed solution containing tellurium elemental nanotubes (such as figure 1 shown), lower the solution temperature to 120°C for use;

[0043] 0.485g (2mmol) of bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) The particles are mixed with 5ml of ethylene glycol, and the mixed solution is heated to 80°C under magnetic stirring. When the solution is colorless and transparent, use a pipette gun to inject it into the tellurium nanotube solution at 120°C and keep it warm for one hour and then cool it down to room temperature. ...

Embodiment 2

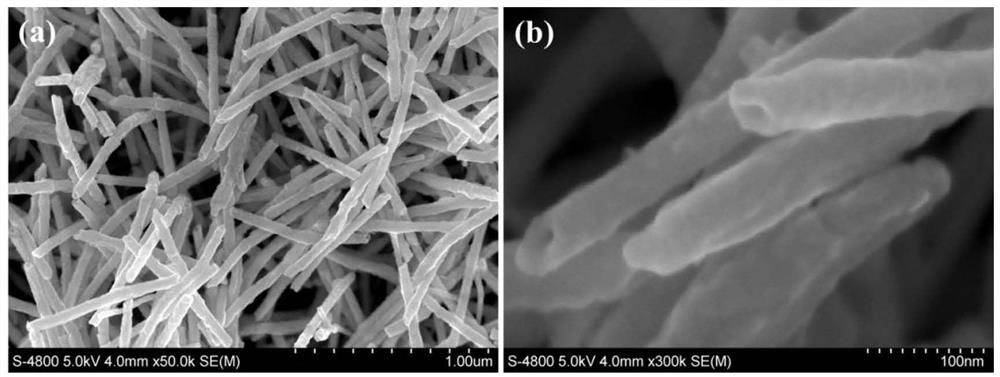

[0046] 0.2394g (1.5mmol) of TeO 2 , 0.5g PVP and 5.6g (10mmol) KOH, mixed and dissolved in 30ml EG at room temperature, fully dissolved into a transparent liquid by magnetic stirring; then poured into a 100ml three-necked bottle, under nitrogen protection, circulating water cooling and Under the condition of magnetic stirring, heat the mixed solution to 130°C, quickly inject 0.25ml of hydrazine hydrate with a concentration of 85%, and after 0.5 hours of heat preservation reaction, a mixed solution containing tellurium simple substance nanotubes can be obtained, and the temperature of the solution is lowered to 120°C for use;

[0047] 0.57g (3mmol) of lead acetate trihydrate (Pb(CH 3 COO) 2 ·3H 2 0) mix with 5ml ethylene glycol, under magnetic stirring, the mixed solution is heated to 80 ℃, when the solution is colorless and transparent, it is injected into the tellurium nanotube solution at 120 ℃ with a pipette gun and incubated for one hour and then cooled to room tempera...

Embodiment 3

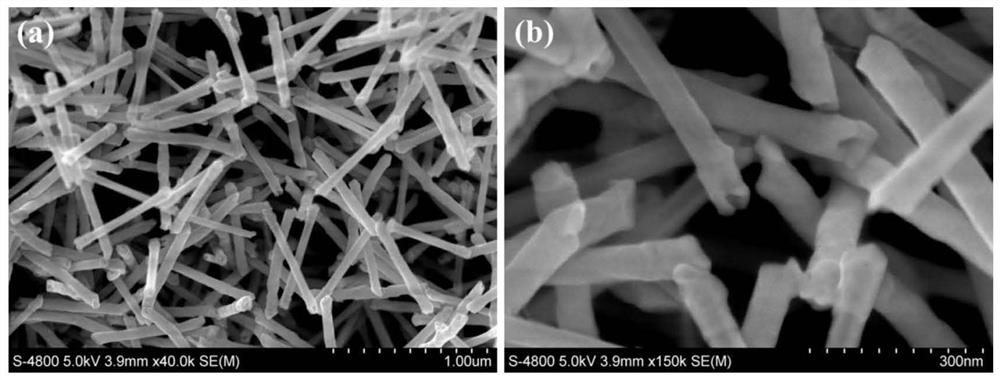

[0049] 0.2394g (1.5mmol) of TeO 2 , 0.5g PVP and 5.6g (10mmol) KOH, mixed and dissolved in 30ml EG at room temperature, fully dissolved into a transparent liquid by magnetic stirring; then poured into a 100ml three-necked bottle, under nitrogen protection, circulating water cooling and Under magnetic stirring conditions, heat the mixed solution to 130°C, quickly inject 0.25ml of hydrazine hydrate with a concentration of 85%, and after 0.5 hours of heat preservation reaction, a mixed solution containing tellurium simple substance nanotubes can be obtained, and the temperature of the solution is cooled to 30°C. use;

[0050] The tellurium nanotube solution was centrifugally washed with a high-speed centrifuge, washed three times with deionized water and absolute ethanol, then dissolved in 5 ml of ethylene glycol, and magnetically stirred at 30°C. At the same time, 0.509g of AgNO 3 Dissolve in 5ml of ethylene glycol, and stir gently with a glass rod for 5min, then drop the AgNO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com