A High Performance Steel Frame Shock Absorbing Bearing

A technology of shock-absorbing bearings and steel frames, which is applied in the direction of earthquake resistance, building components, protective buildings/shelters, etc., can solve the problem of reducing the overall seismic and torsional ability of the structure, and the weak torsional ability of laminated rubber bearings , torsion resistance rubber bearing damage and other problems, to achieve the effect of accelerating the anti-seismic effect, accelerating the attenuation rate of vibration, and strong reset ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

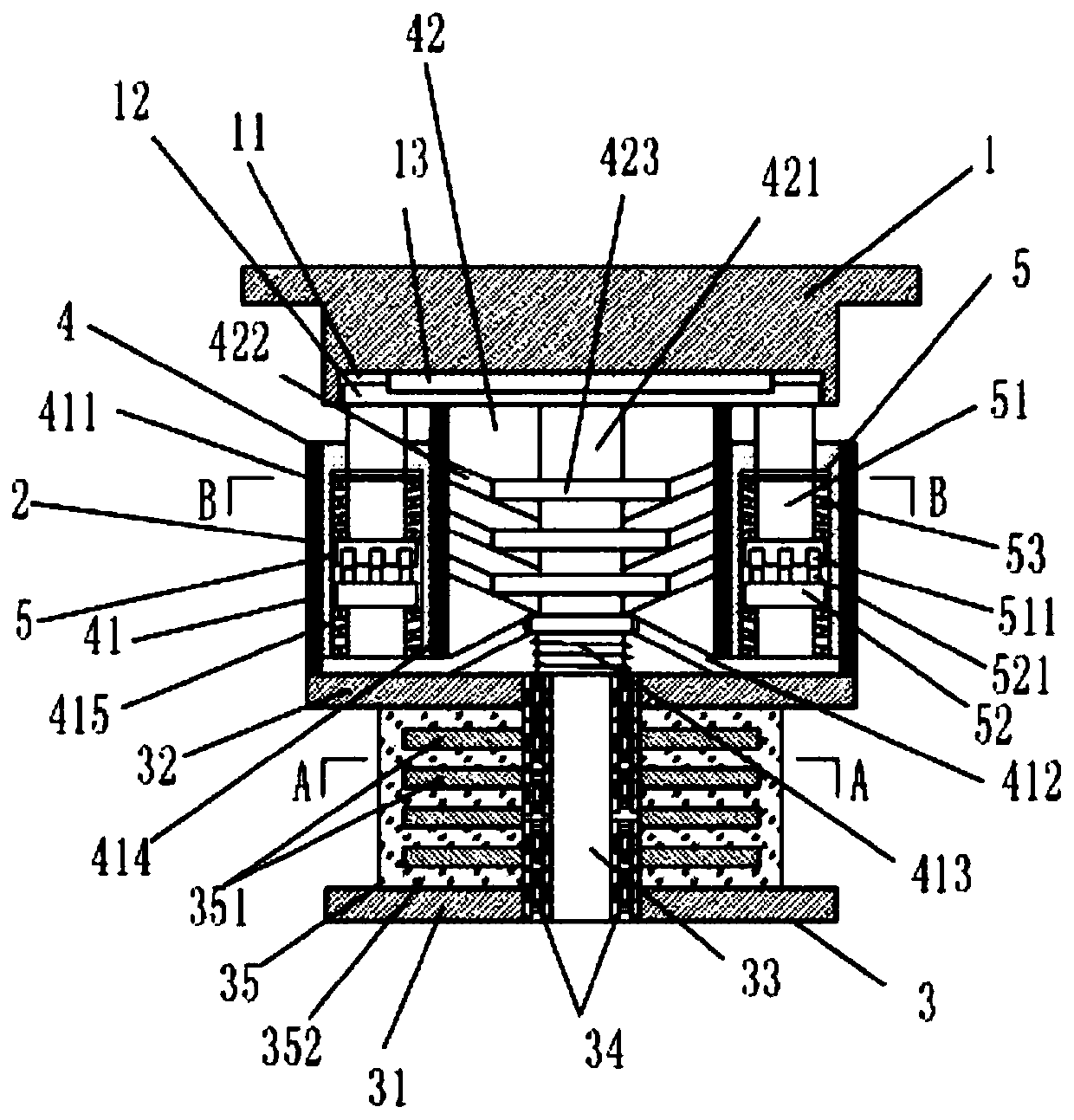

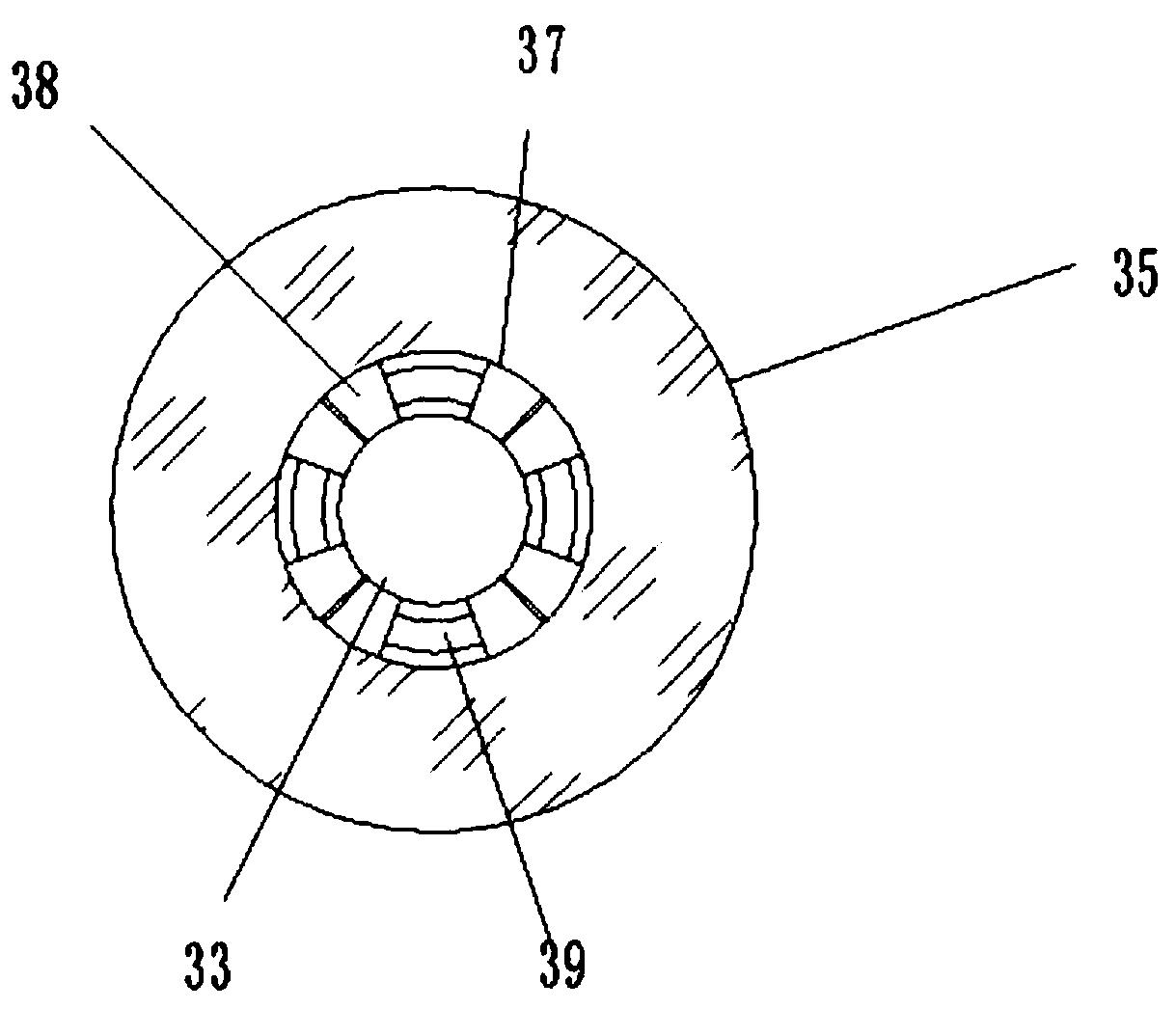

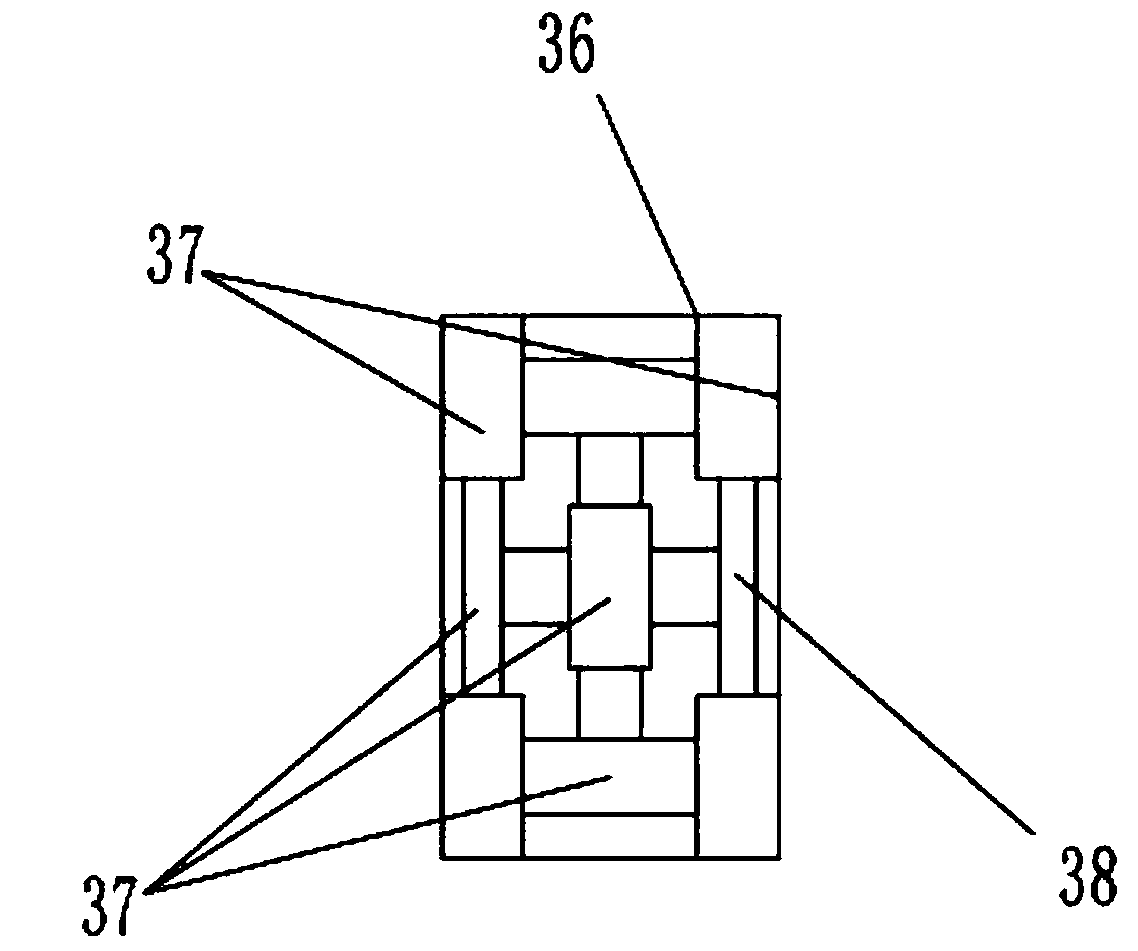

[0022] Such as figure 1 , 2As shown, a high-performance steel frame shock absorber mainly includes a third fixed plate 1 and a support base 2, the third fixed plate 1 is located above the support base 2, and a groove is provided at the lower end of the third fixed plate 1 11. A third connecting plate 12 is provided in the groove 11, and an adhesive plate 13 is arranged between the third connecting plate 12 and the groove 11. The support base 2 includes a horizontal shock-isolation base 3 and a vertical shock-isolation base 4. The horizontal shock-isolation base 3 includes a first fixed plate 31, a second fixed plate 32, a lead body 33, and a buffer sleeve 34. A shock-isolating body 35 is arranged between the first fixed plate 31 and the second fixed plate 32, and the lead body 33 is vertically It runs through the middle of the first fixed plate 31, the second fixed plate 32 and the shock-isolating body 35. The shock-isolating body 35 is made of several steel plates 2 and bond...

Embodiment 2

[0026] The difference from Example 1 is the material of the damping layer 415, which consists of the following components in parts by weight: 35 parts of methyl hydrogen-containing silicone oil, 12 parts of polyvinylidene fluoride, 25 parts of fiber, and 30 parts of fluorocarbon resin , 15 parts of graphene, 20 parts of dibenzoyl peroxide, and 15 parts of mica powder. The preparation method is: add them to the mixer in turn for mixing and stirring, and heat up to 220°C under nitrogen atmosphere, and the stirring rate is 1800r / min , heat preservation treatment for 30 minutes, adjust the pressure to 0.3MPa, melt treatment at a temperature of 330 ° C, and then homogenize treatment, and then pressure molding at room temperature.

[0027] When an earthquake occurs, the restraining block 36 in the buffer sleeve 34 can squeeze the lead body 33, and the restraining block 36 can disperse the external force through the elastic rod 38 to reduce the damage and fracture caused by the deform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com