Cement concrete road structure with pervious isolating filter layer and combined layer and its construction method

A technology of pavement structure and isolation layer, which is applied to the direction of cohesive pavement paved on site, roads, roads, etc., can solve the problems of not being able to slide each other, road surface damage, and blocking, so as to achieve convenient material acquisition, reduce fracture or fatigue damage, and reduce The effect of breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

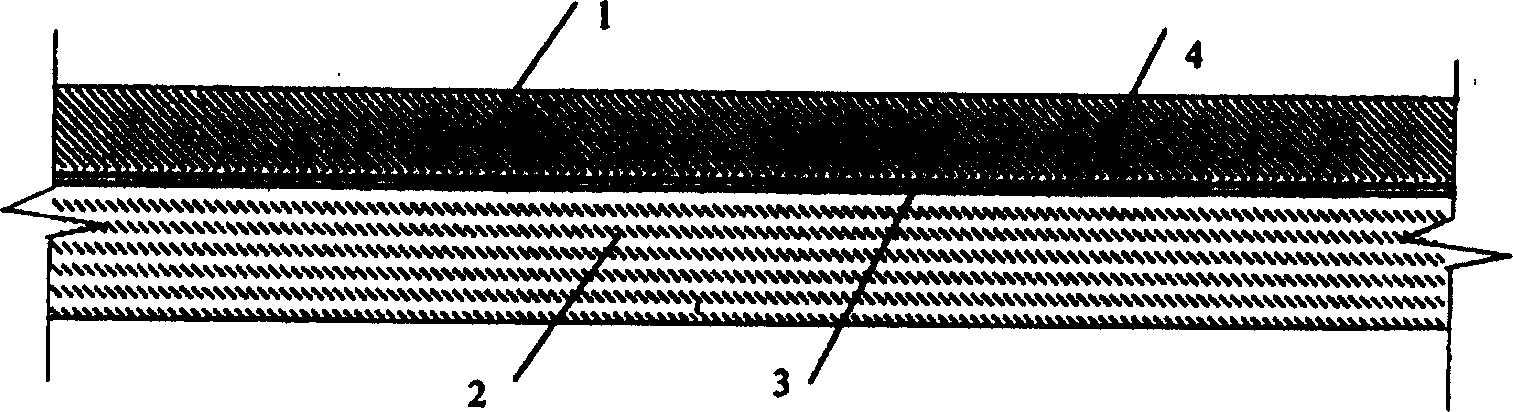

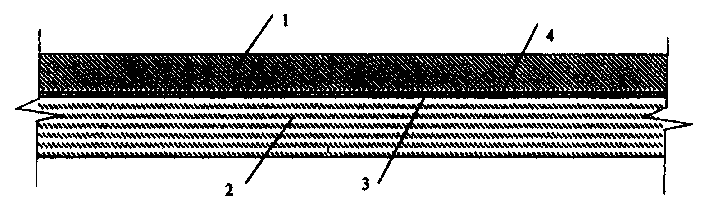

[0025] As shown in the drawings, the isolation layer 3 has a bonding layer 4 and a cement concrete surface layer 1 on it, and a base layer 2 on the bottom.

[0026] When building a new cement concrete pavement, directly lay a layer of uniform, flat, water-permeable, water-absorbing, but capable of filtering out cement particles and other solid particles in the cement mortar on the surface of the base layer 2 after rolling and leveling. 1. The isolation layer 3 formed by non-woven fabrics, and then on the permeable filter slurry isolation layer 3, lay a layer of uniform and smooth water-permeable material by hand or machine and after the cement mortar is set, it can be naturally firmly bonded or combined with the cement concrete. The bonding layer 4 formed by fabric or wire mesh, and then the cement concrete surface layer 1 is directly poured on the bonding layer 4 . In this way, a cement concrete pavement structure is formed in which a permeable filter slurry isolation layer 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com