Pulsed tube bundle heat exchange assembly and fused salt heat storage tank thereof

A technology of heat exchange components and heat exchange tubes, applied in heat storage equipment, indirect heat exchangers, heat exchanger types, etc., can solve the problem of uneven heating of high temperature fluid, long heat storage time of molten salt, and slow heat storage speed problem, to achieve the effect of convenient control, simple structure and reduced scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

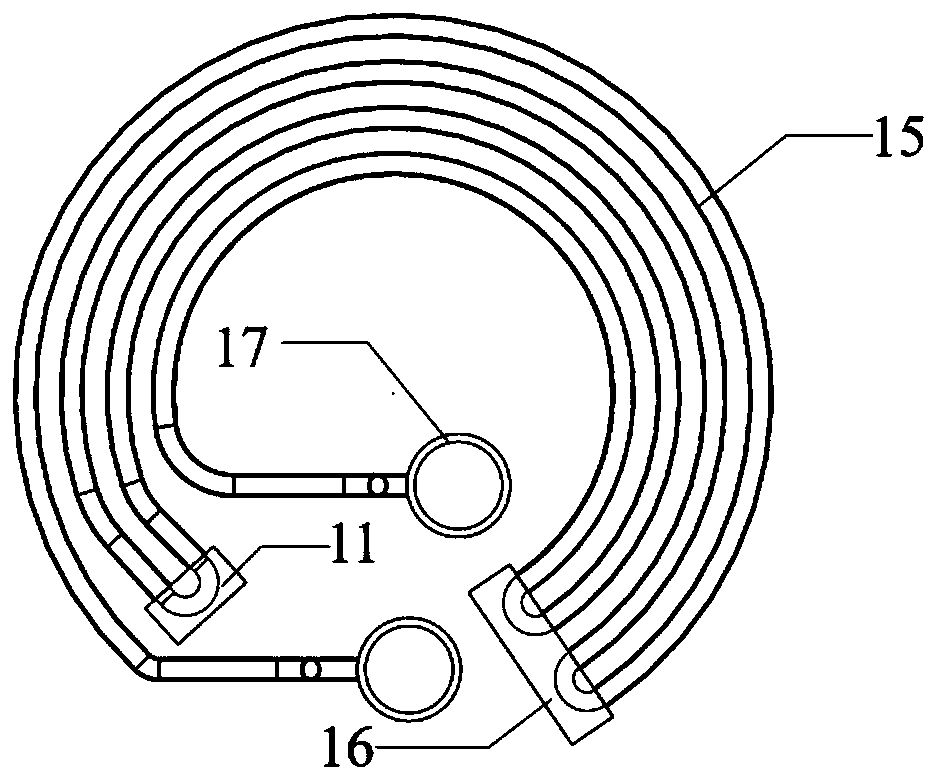

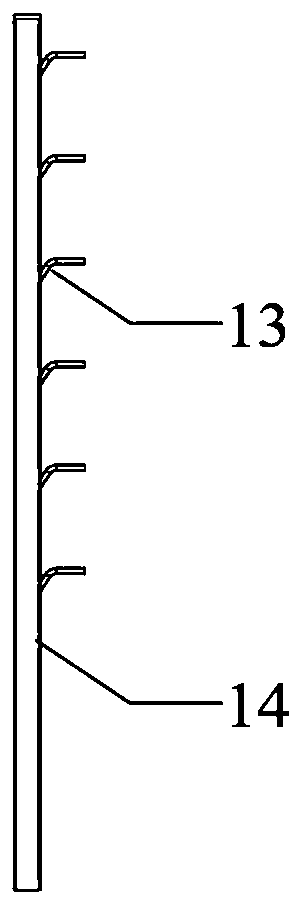

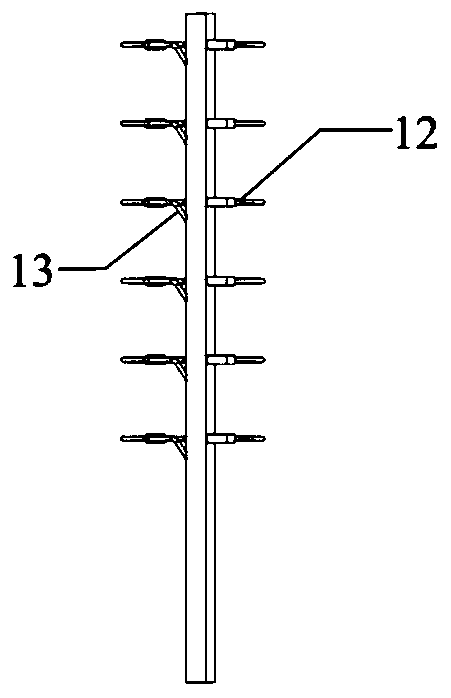

[0042] Figure 1-3 A pulsating tube bundle heat exchange assembly 6 is shown, the assembly includes a coiled pipe 12, an inlet riser 14 and an outlet riser 16, and there are multiple coils 12, such as image 3 As shown, there are multiple sets along the height direction, and each coil 12 includes a plurality of arc-shaped heat exchange tubes 15, and the ends of adjacent heat exchange tubes 15 are connected, so that the plurality of heat exchange tubes 15 form a series structure, And make the end of the heat exchange tube form the free end of the heat exchange tube ( figure 1 set the position of the load-bearing block), the plurality of heat exchange tubes are distributed sequentially from the center of the circle to the outside along the same circle center, the inlet riser 14 is connected to the inlet of the outermost heat exchange tube, and the outlet riser 17 is connected to the innermost heat exchange tube The outlet of the pipe 15, the inlet standpipe 14 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com