Method for lithium supplement of lithium ion battery negative electrode plate, lithium-supplement negative electrode plate and lithium ion battery

A technology for lithium-ion batteries and negative electrodes, which is applied in lithium-ion battery negative electrodes, lithium-supplemented negative electrodes, and lithium-ion batteries. It can solve the problems of high toxicity of lithium sources, improve the cycle capacity retention rate, and benefit the industry. The effect of production and improvement of the first Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

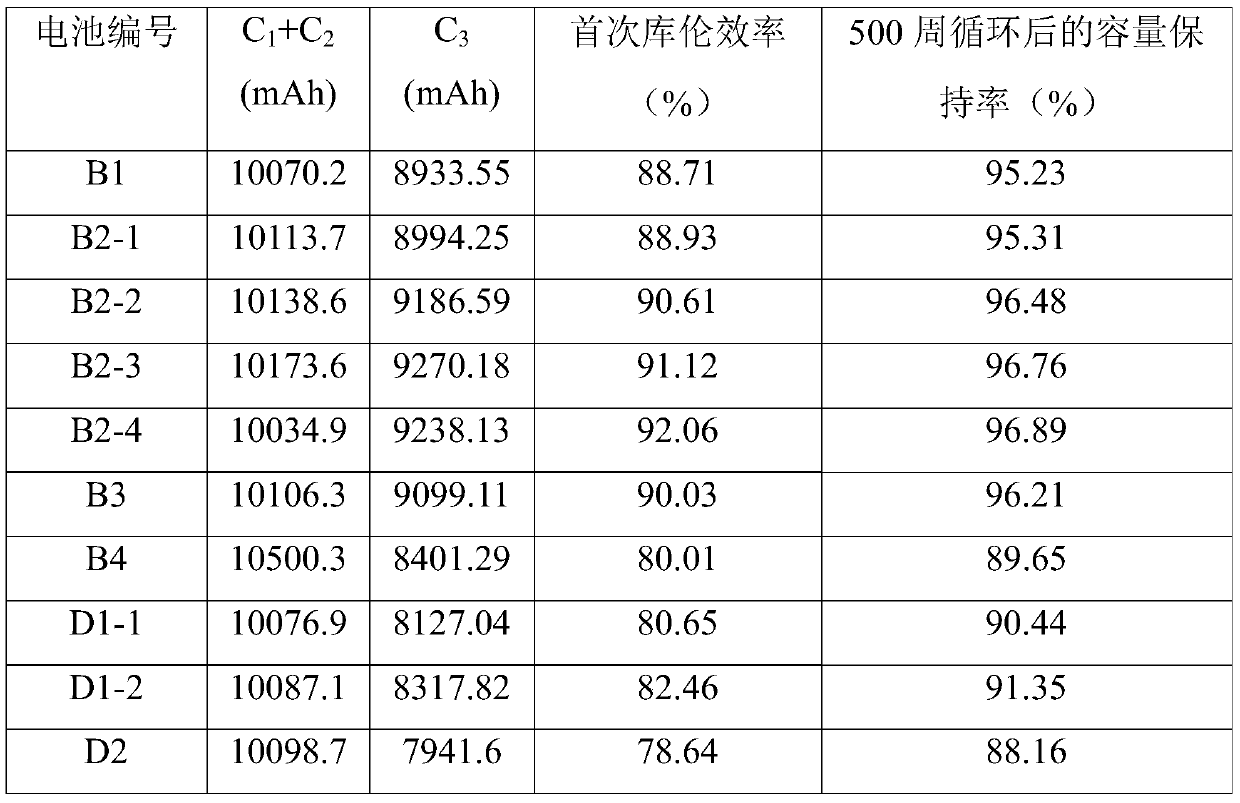

[0028] At room temperature, lithium carbonate is dissolved in aqueous carbonic acid solution to form a lithium bicarbonate aqueous solution with a concentration of 0.02M, and then the lithium bicarbonate aqueous solution is evenly sprayed on the negative electrode sheet (the negative electrode active material is artificial graphite, Jiangxi Zichen Technology Co., Ltd., brand The surface of FT-1, the same below), was dried at 90° C. and 0.05 MPa for 6 hours to obtain a lithium-supplementing negative electrode sheet containing 1% by weight of lithium carbonate on the surface.

Embodiment 2

[0030] At room temperature, lithium carbonate was dissolved in aqueous carbonic acid solution to form a lithium bicarbonate aqueous solution with a concentration of 0.03M, and then the lithium bicarbonate aqueous solution was evenly sprayed on the surface of the negative electrode sheet, and dried at 95°C and 0.1MPa for 2 hours to obtain a surface containing A lithium-replenishing negative electrode sheet of 3% by weight lithium carbonate.

Embodiment 3

[0032] At room temperature, lithium carbonate was dissolved in aqueous carbonic acid solution to form an aqueous solution of lithium bicarbonate with a concentration of 0.06M, and then the aqueous solution of lithium bicarbonate was evenly sprayed on the surface of the negative electrode sheet, and dried at 85°C and 0.01MPa for 8 hours to obtain a surface containing Lithium-supplementing negative electrode sheet with 6% by weight lithium carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com