Method for preparing powder comprising particles of triuranium octoxide and particles of plutonium dioxide

A technology for uranium 8 oxide and plutonium dioxide, which is used in the field of recycling spent nuclear fuel and can solve problems such as dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

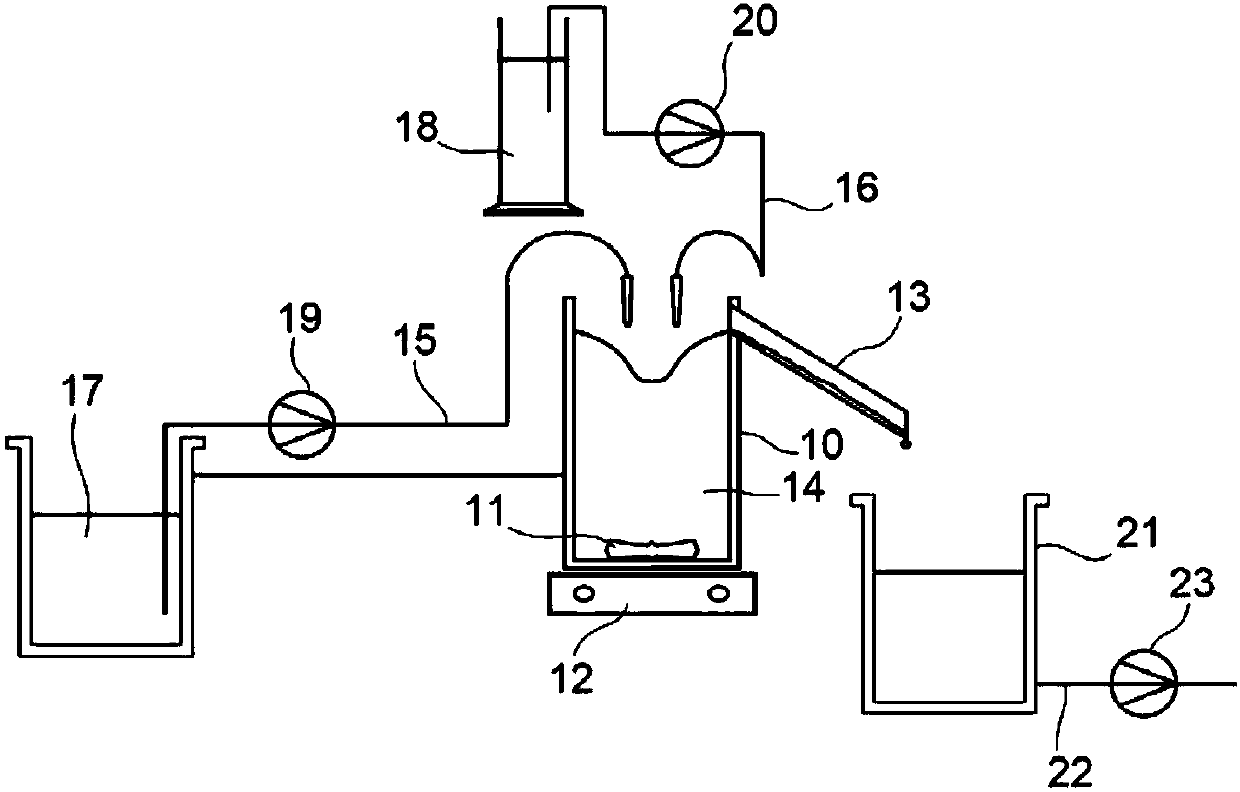

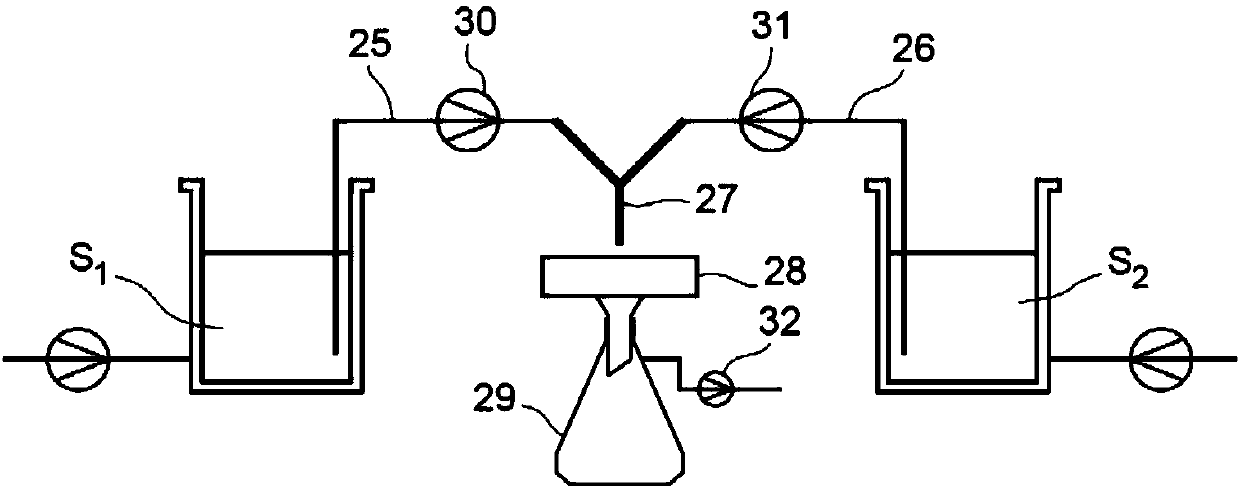

Method used

Image

Examples

Embodiment Construction

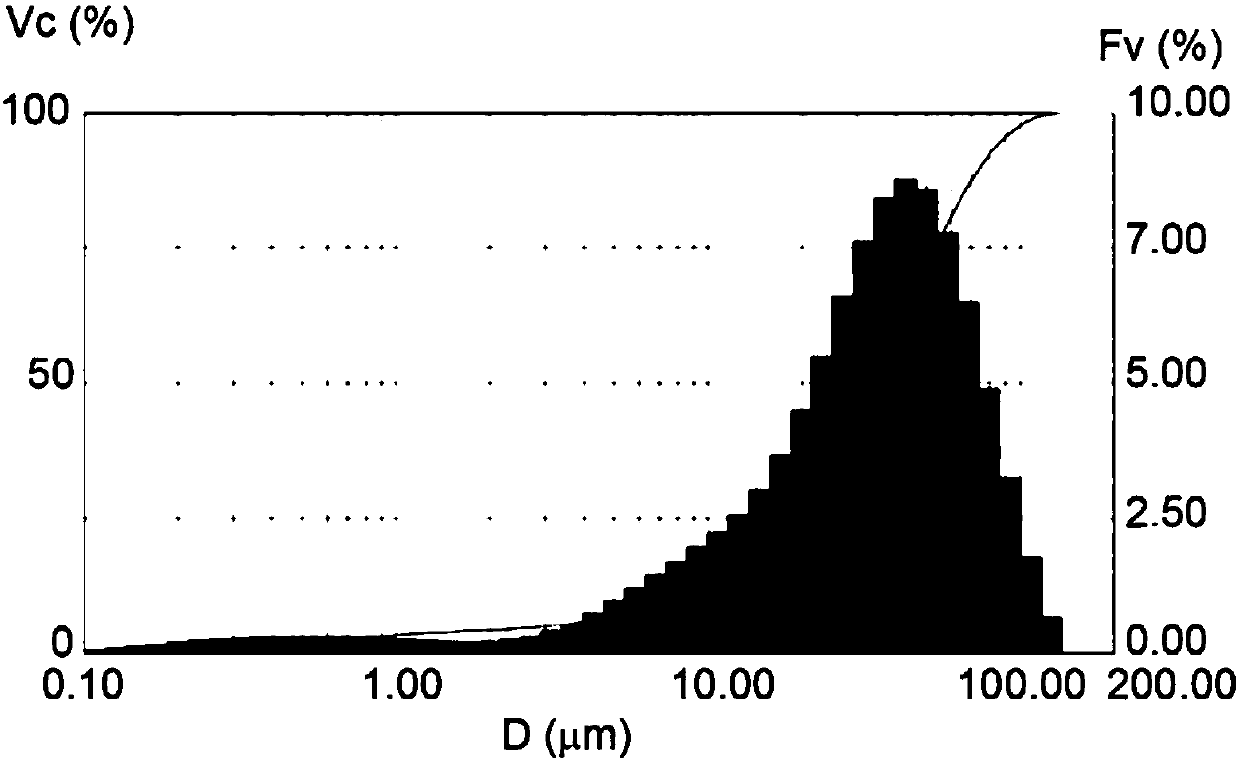

[0093] This example concerns an aqueous solution A of uranium(IV) nitrate 1 and an aqueous solution of plutonium(IV) nitrate and uranium(VI) nitrate A' 1 Prepared by U 3 o 8 Particles and PuO 2 A powder consisting of a mixture of particles.

[0094] Aqueous solution A 1 Including 0.15mol / L uranium(IV) nitrate or formula U(NO 3 ) 4 Tetravalent uranium nitrate, 2.5mol / L nitric acid and 0.06mol / L hydrazine ion N 2 h 5 + (as hydrazine nitrate N 2 h 5 NO 3 Added in the form of), while the aqueous solution A' 1 Including 0.15mol / L of the formula Pu(NO 3 ) 4 plutonium (IV) nitrate, 0.038mol / L uranium (VI) nitrate or formula UO 2 (NO 3 ) 2 Uranyl nitrate and 2.5mol / L nitric acid.

[0095] Aqueous solution A 1 Concentration of uranium(IV) nitrate in medium and aqueous solution A' 1 The concentration of plutonium(IV) nitrate in the medium is chosen such that, taking into account the volumes of aqueous solutions involved, the starting Pu(IV) / U(IV)+Pu(IV) molar ratio i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com