Novel composite lightweight-material low-density cement slurry system and preparation method thereof

A low-density, cement slurry technology, applied in the field of petroleum cementing, can solve problems such as lost circulation, the implementation of production stimulation operations affecting the cementing quality, etc., and achieve the effect of wide production area, good ability to control water loss, and early strength improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

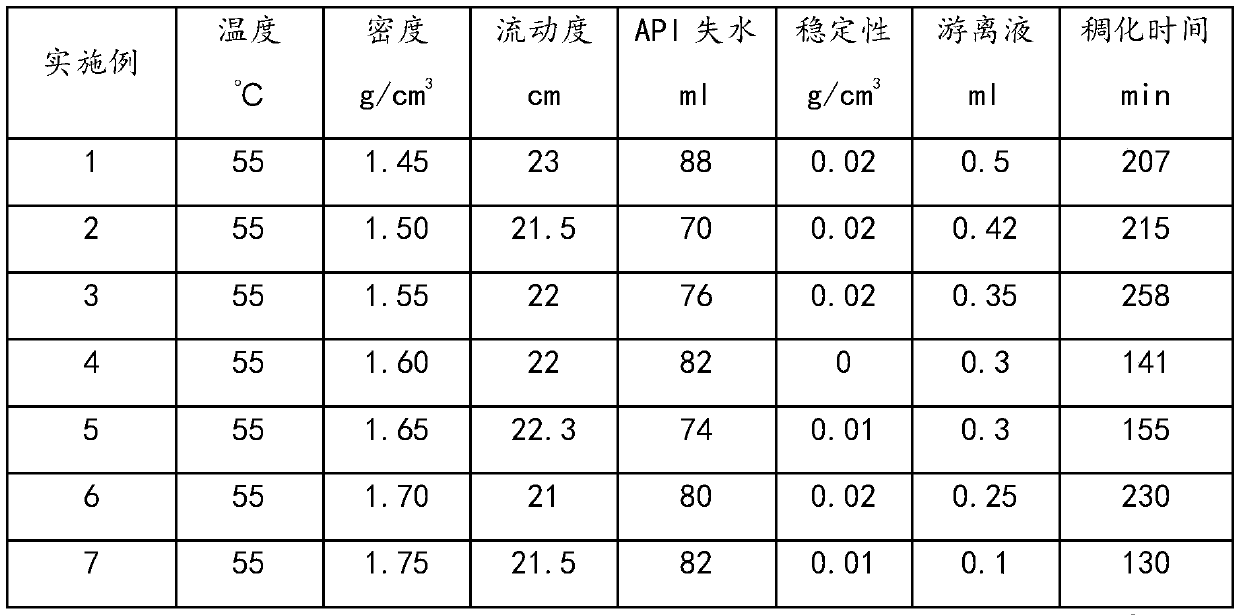

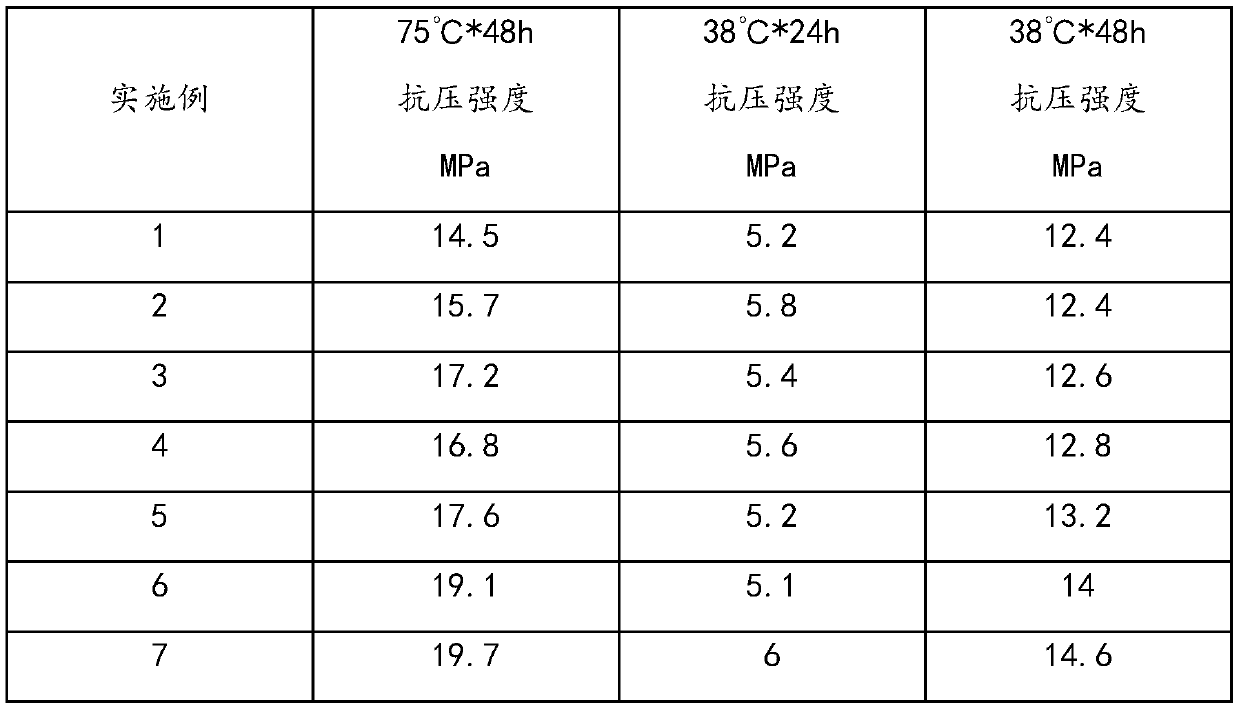

Embodiment 1

[0022] The low-density cement slurry system of the new composite lightening material in this example is composed of the following materials: G grade oil well cement 100kg, fresh water 100kg, CP-56 new composite lightening material 50kg, G33S oil well cement fluid loss reducer 1.5kg, GH-9 oil well Cement retarder 0.3kg, G401 oil well cement expansion agent 1.5kg, USZ oil well cement drag reducer 0.3kg and XP-1 defoamer 0.2kg.

[0023] The CP-56 new composite lightening material is composed of the following materials: 12kg ultrafine slag, 20kg ultrafine cement, 38kg active microsilica, 4kg G203A oil well cement early strength agent, G204 oil well cement early strength agent 4kg and G208 oil well cement early strength agent Strong agent 3kg. The ultra-fine slag is S95 grade granulated blast furnace slag powder; the particle size of the ultra-fine cement is 8±1 micron; the particle size of the active micro-silicon powder is 160-300 mesh. The manufacturer of the active micro-silic...

Embodiment 2

[0033] A new composite lightening material low-density cement slurry system in this embodiment is composed of the following materials: G grade oil well cement 100kg, fresh water 90kg, CP-56 new composite lightening material 40kg, G33S oil well cement fluid loss reducer 1.2kg, GH -9 oil well cement retarder 0.2kg, G401 oil well cement expansion agent 1.2kg, USZ oil well cement drag reducer 0.3kg and XP-1 defoamer 0.2kg.

[0034]The CP-56 new composite lightening material is composed of the following materials: 12kg ultrafine slag, 20kg ultrafine cement, 38kg active microsilica, 4kg G203A oil well cement early strength agent, G204 oil well cement early strength agent 4kg and G208 oil well cement early strength agent Strong agent 3kg. The ultra-fine slag is S95 grade granulated blast furnace slag powder; the particle size of the ultra-fine cement is 8±1 micron; the particle size of the active micro-silicon powder is 160-300 mesh. The manufacturer of the active micro-silica fume ...

Embodiment 3

[0041] A new composite lightening material low-density cement slurry system in this embodiment is composed of the following materials: G grade oil well cement 100kg, fresh water 78kg, CP-56 new composite lightening material 30kg, G33S oil well cement fluid loss reducer 1.6kg, GH -9 oil well cement retarder 0.3kg, G401 oil well cement expansion agent 1.3kg, USZ oil well cement drag reducer 0.3kg and XP-1 defoamer 0.2kg.

[0042] The CP-56 new composite lightening material is composed of the following materials: 12kg ultrafine slag, 20kg ultrafine cement, 38kg active microsilica, 4kg G203A oil well cement early strength agent, G204 oil well cement early strength agent 4kg and G208 oil well cement early strength agent Strong agent 3kg. The ultra-fine slag is S95 grade granulated blast furnace slag powder; the particle size of the ultra-fine cement is 8±1 micron; the particle size of the active micro-silicon powder is 160-300 mesh. The manufacturer of the active micro-silica fume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com