Long-span arch bridge with single-leaf hyperboloid variable cross-section concrete-filled steel tube space truss arch rib

A technology of steel tube concrete and space truss, which is applied in the direction of arch bridges, erection/assembly bridges, bridges, etc. It can solve the problems of increased segmental weight at the vault, decreased stability of the arch bridge structure, and difficulties in hoisting and construction of the arch bridge, and achieves hoisting weight reduction. , improve the force condition, and the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

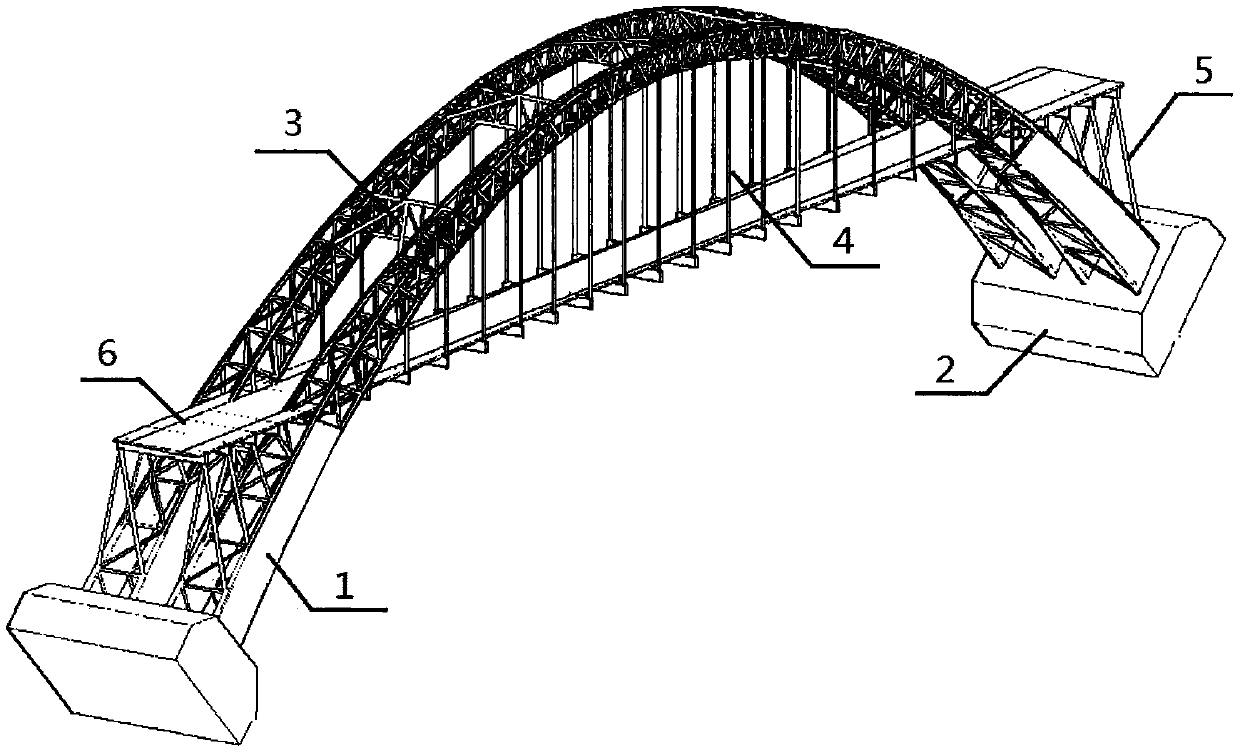

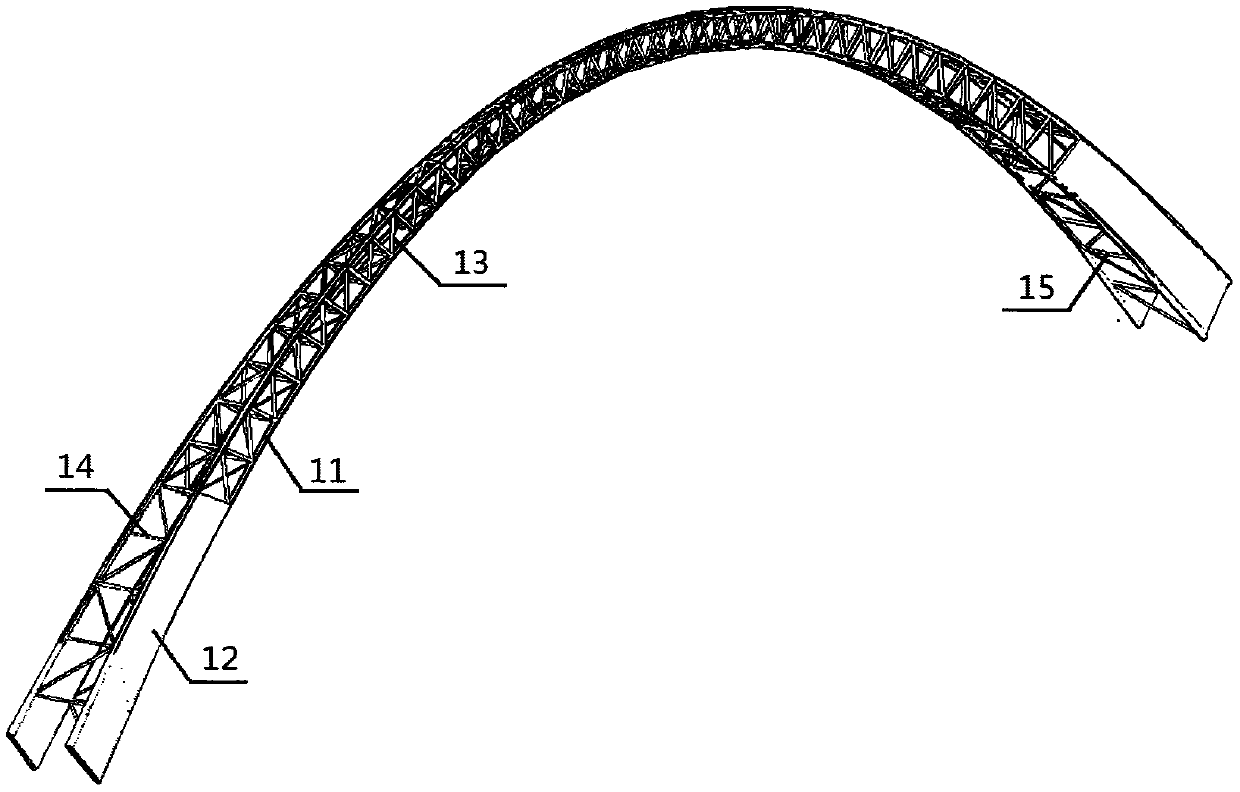

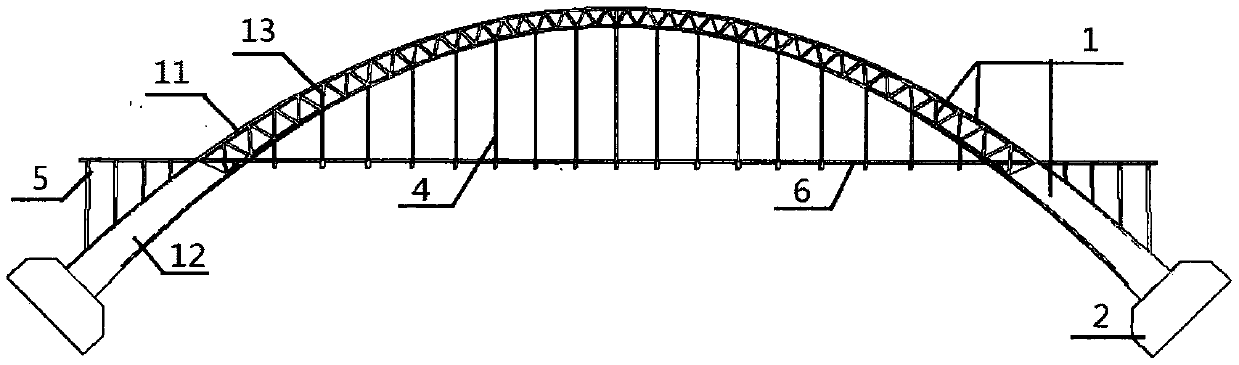

[0053] A super-long-span arch bridge with single-leaf hyperboloid variable-section concrete-filled steel pipe space truss arch ribs of the present invention consists of limb space truss arch ribs 1, arch bridge foundation 2, K-shaped wind braces 3, slings 4, columns 5 and bridge The noodle system consists of 6 components. A limb space truss arch rib 1 is arranged on the left and right sides of the super-long-span arch bridge, and each limb space truss arch rib 1 includes four single-leaf hyperboloid variable-section steel pipe concrete arch ribs 11 in the shape of a basket arch. In the left and right oblique planes of the arch rib 1 of the limb space truss in the shape of a basket arch, the segment from the arch foot to the 1 / 4 section, the corrugated steel web 12 is set between the upper and lower chords, and the section from the 1 / 4 section to the arch In the segment of the top, steel pipe diagonal rods 13 are arranged on the abdomen between the upper and lower chords. The ...

Embodiment 2

[0057] The construction method of the ultra-large-span arch bridge of the single-leaf hyperboloid variable-section concrete-filled steel tube space truss arch rib of the present invention comprises the following steps:

[0058] Step 1: According to the geological topography, landform conditions and navigation requirements, select the bridge site for the ultra-long-span concrete-filled steel tube arch bridge, excavate the foundation pit, and construct the arch bridge foundation 2.

[0059] Step 2: In the prefabrication processing plant, determine the centroid line position of each single-leaf hyperboloid arched steel pipe arch 11 of the limb space truss arch rib 1, divide the number of hoisting segments, and unload fan-shaped steel plates. The barrel machine rolls the fan-shaped steel plate into a conical steel pipe segment, and uses pyrotechnic bending to form a conical steel pipe bending segment. Multiple conical steel pipe bending segments are assembled into a single-leaf hyp...

Embodiment 3

[0066] A 1,000-meter super-long-span highway bridge in a canyon in the southwest, the design scheme of the super-long-span arch bridge adopts the single-leaf hyperboloid variable-section steel pipe concrete space truss arch rib, the design load is the first-class highway, and the bridge deck width is 32 meters (left sidewalk 2 meters + carriageway 28 meters + right sidewalk 2 meters), the boom spacing is 25 meters, the rise-span ratio is 1 / 4, the arch bridge rise height is 250 meters, and the arch axis coefficient is 1.75. A limb space truss arch rib, the limb space truss arch rib is formed by two oblique arch trusses leaning towards each other to form a basket arch shape.

[0067] The cross-section height of the arch rib of the limb space truss is 15 meters, and the height of the cross-section at the foot of the arch is 30 meters. The distance between the arch feet of the arch trusses is 30 meters, the lateral inclination angle between the two planar arch trusses is 3.5°, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com