A magnetoacoustic emission detection method for creep damage of ferromagnetic metal components

A technology for acoustic emission detection and metal components, which is applied in material analysis using acoustic emission technology, processing response signals of detection, and analysis of solids using acoustic/ultrasonic/infrasonic waves. Time and other problems, to achieve the effect of convenient extraction, increased signal-to-noise ratio, and easy identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

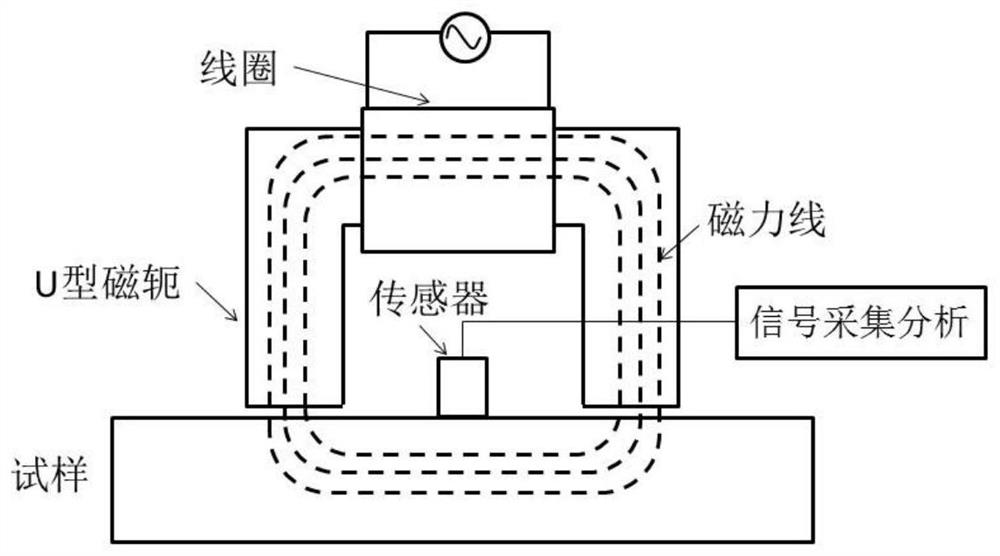

[0041] 1) Place the self-made U-shaped electromagnetic yoke and the acoustic emission sensor in the central area of the 1Cr5Mo steel sample that has not been subjected to the creep test in a relatively fixed position.

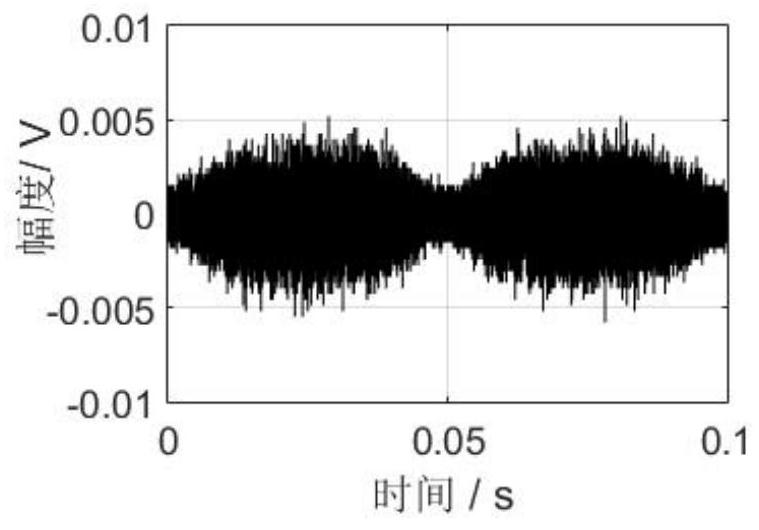

[0042] 2) Load a triangular wave voltage signal with a periodic symmetry of 50% to the coil of the U-shaped electromagnetic yoke. The frequency of the signal is 10 Hz. The voltage signal is generated by a function generator and input to the coil after being amplified 10 times by a power amplifier. Since the MAE signal is generated under the alternating magnetic field excited by the triangular wave voltage signal with a symmetry of 50%, the 1Cr5Mo steel sample generates two identical MAE signals within one magnetization period, that is, the frequency of the MAE signal is equal to the frequency of the alternating magnetic field double.

[0043] Use the function generator to increase the peak-to-peak value of the output voltage signal from 0.1Vpp with a gradient...

Embodiment 2

[0057] The same as the member to be tested and the detection steps described in Example 1, only the steps of adjusting the magnetomotive force are different, as follows:

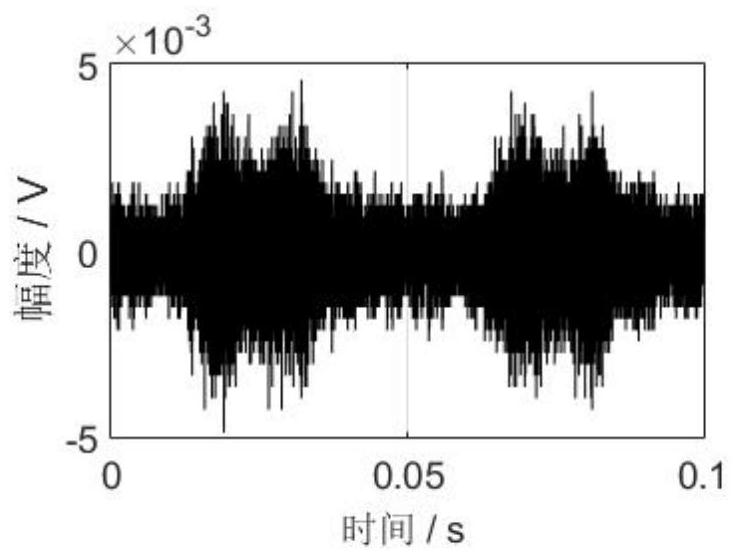

[0058] By adjusting the nominal diameter of the coil enameled wire to obtain a "T"-shaped envelope, the number of turns of the U-shaped electromagnetic yoke coil is 800 turns, and the nominal diameter of the enameled wire for making the coil is 0.04mm, and the standard Enameled wires with diameters of 0.08mm, 0.12mm, 0.16mm, 0.2mm, 0.25mm, 0.31mm, 0.35mm, 0.4mm, 0.45mm, 0.5mm, 0.55mm, 0.60mm, 0.64mm, 0.69mm and 0.72mm are used instead Enameled wire with a nominal diameter of 0.04mm is wound on the core with a coil having the same number of turns. Keep the voltage signal unchanged, collect the MAE signal and the corresponding coil current under the coils wound by enameled wires with various nominal diameters, and find that the MAE signal of the "T"-shaped envelope is generated when the nominal diameter of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com