Preparation method of Gan-based light-emitting diode epitaxial wafer

A technology of light-emitting diodes and epitaxial wafers, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of low hole concentration in the P-type GaN layer, reduce the formation of Mg-H complexes, and avoid Effect of non-radiative recombination and high crystal growth quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

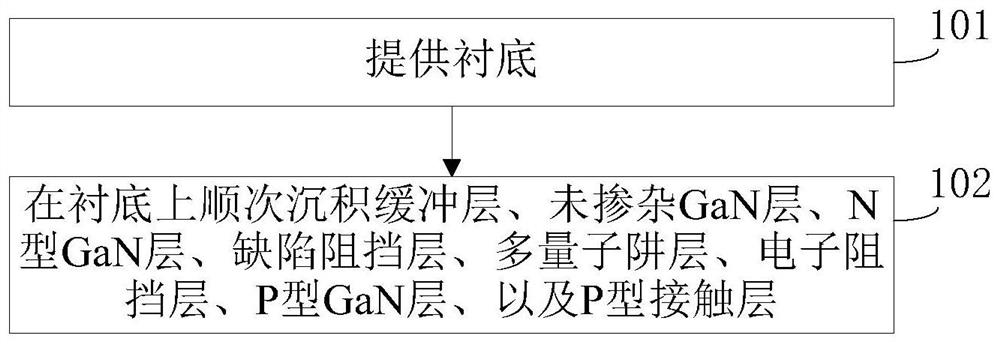

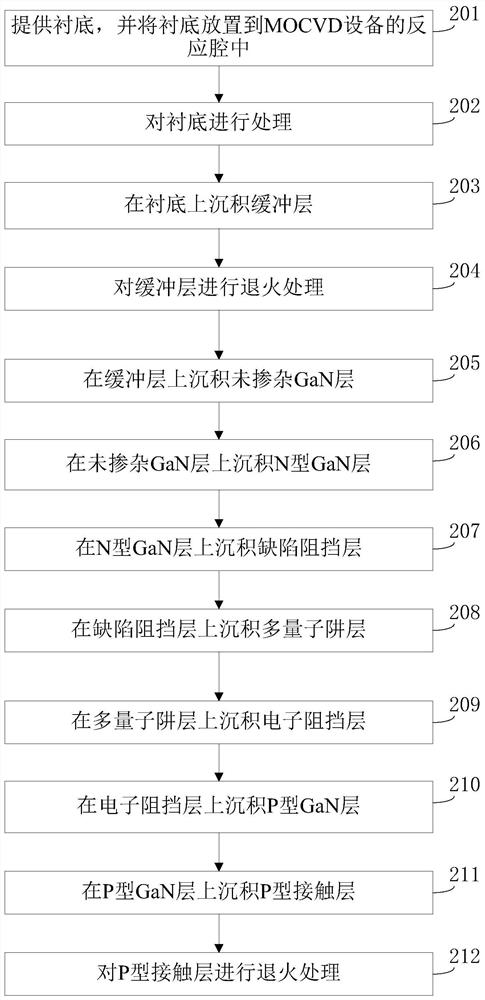

[0021] In order to make the objects, technical solutions, and advantages of the present invention, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

[0022] In the relevant technique, the P-type GaN layer adopts N 2 Ho 2 The mixed gas is used as a carrier gas, since Mg is required in the p-type GaN layer to produce sufficient holes, but the MG is soluble in GaN low, easy to form Mg-H complexes with h, which caused by deep levels caused by these complexes Receptors will cause non-radiation complications caused by the hole trap to reduce the concentration of the hole. In addition, the H atom is small, the Mo (Metalorganic Source, Metal Organic Organic Source) is less; the N atom is large, and the Mo brought into. Mo is a high-purity metal organic compound material, which is a metal organic chemical gas phase epitaxial and deposited raw materials. When the B-type GaN layer is not high, the voltage of the L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com