A flip-chip LED epitaxial wafer with a Gaas-based roughened layer structure and its manufacturing method

A technology of LED epitaxial wafers and roughened layers, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of low brightness, poor reliability and stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

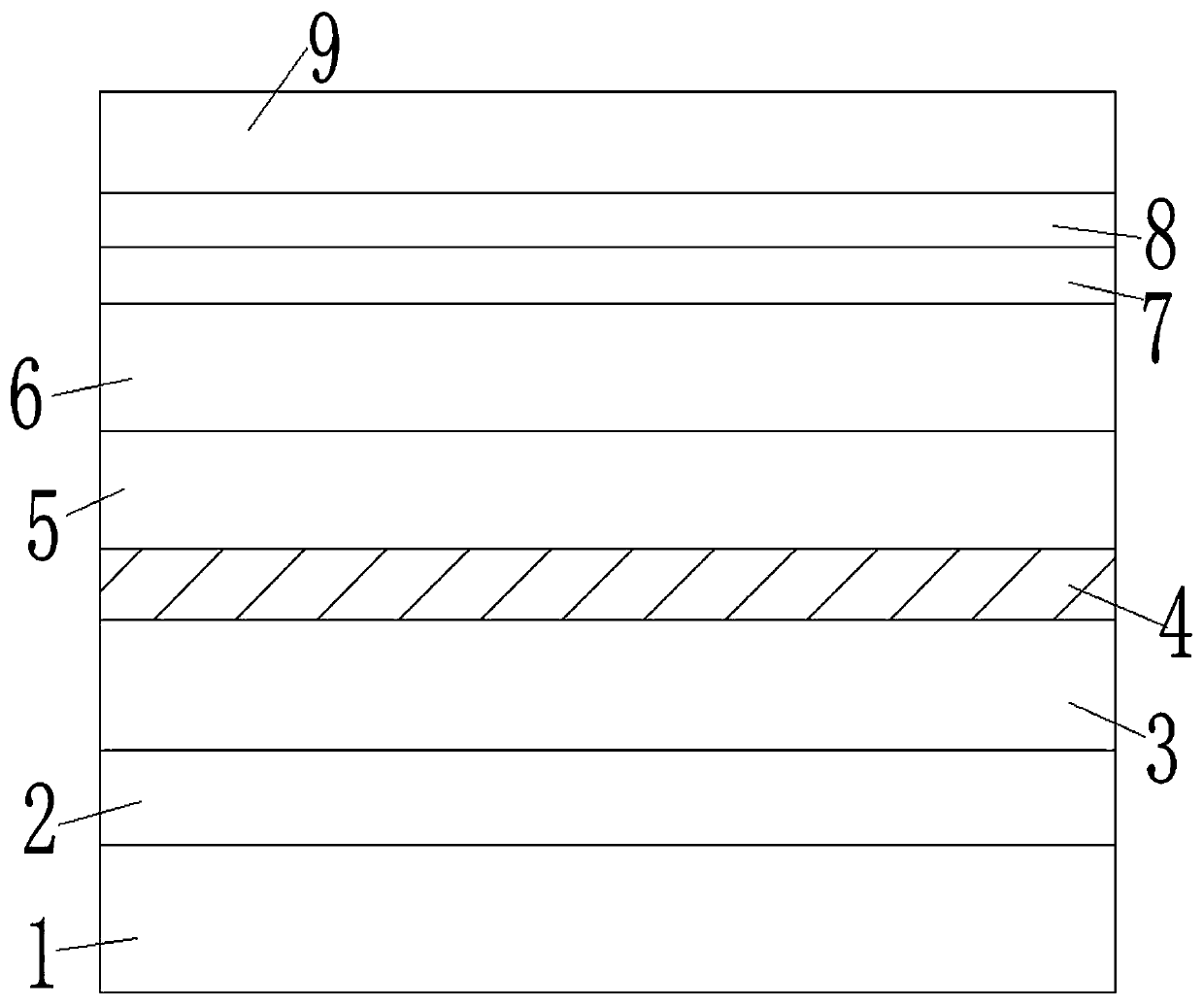

[0036] Example 1, the preferred thickness of the GaAs buffer layer 1 is 150nm, the preferred thickness of the corrosion barrier layer 2 is 400nm, the preferred thickness of the ohmic contact layer 3 is 150nm, and the preferred thickness of the N-AlxGa1-xInP first roughened layer 4 is 3um , N-Al x Ga 1- x The preferred thickness of the As second roughening layer 5 is 0.45um, the preferred thickness of the lower confinement layer 6 is 500nm, the preferred thickness of the multi-quantum well light-emitting region 7 is 0.1um, the preferred thickness of the upper confinement layer 8 is 300nm, the current spreading layer 9 The preferred thickness is 3um.

[0037] The specific preparation method of the flip-chip LED epitaxial wafer with the above-mentioned GaAs-based roughened layer structure is as follows, which sequentially includes the following steps:

[0038] a) Place the GaAs substrate in the growth chamber of the MOCVD equipment, and pass through , heat up to 750±20°C and...

Embodiment 2

[0054] The doping concentration in step b) is 1E17-5E18 atoms / , the doping concentration in step c) is 1E17-5E18 atoms / , the doping concentration in step d) is 1E18-5E18 atoms / , the doping concentration in step e) is 1E17-1E18 atoms / , the doping concentration of AlGaAs in step f) is 1E17-5E18 atoms / , the doping concentration of AlAs is 1E17-5E18 atoms / , the doping concentration in step g) is 1E17-5E18 atoms / , the doping concentration in step h) is 1E18-5E18 atoms / , the doping concentration in step i) is 1E17-1E18 atoms / , the doping concentration in step g) is 5E18-1E20 atoms / . Preferably, the doping concentration in step b) is 2E18 atoms / , the doping concentration in step c) is 5E17 atoms / , the doping concentration in step d) is 1E18 atoms / , the doping concentration in step e) is 5E17 atoms / , the doping concentration of AlGaAs in step f) is 5E17 atoms / , the doping concentration of AlAs is 1E18 atoms / , the doping concentration in ste...

Embodiment 3

[0056] GaAs buffer layer 1, N-Al x Ga 1-x InP first roughening layer 4, N-Al x Ga 1-x The N-type dopant source of the As second roughening layer 5 and the AlInP lower confinement layer 6 is ; The P-type dopant source of confinement layer 8 and current spreading layer 9 on AlInP is .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com