A high-efficiency ingot casting furnace with heat balance

A heat-balanced, high-efficiency technology, applied in single crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problems of prolonging heating time, reducing processing efficiency, energy waste, etc., to improve the utilization rate of heat, optimize Processing process, the effect of increasing the melting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

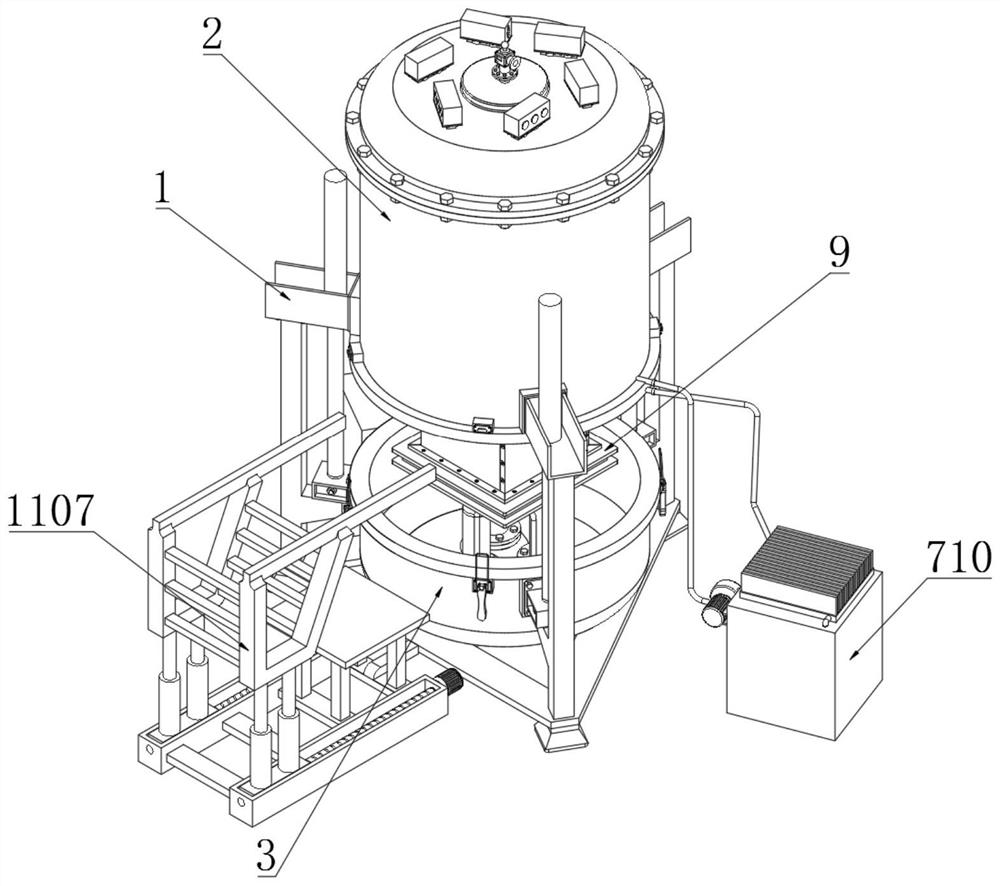

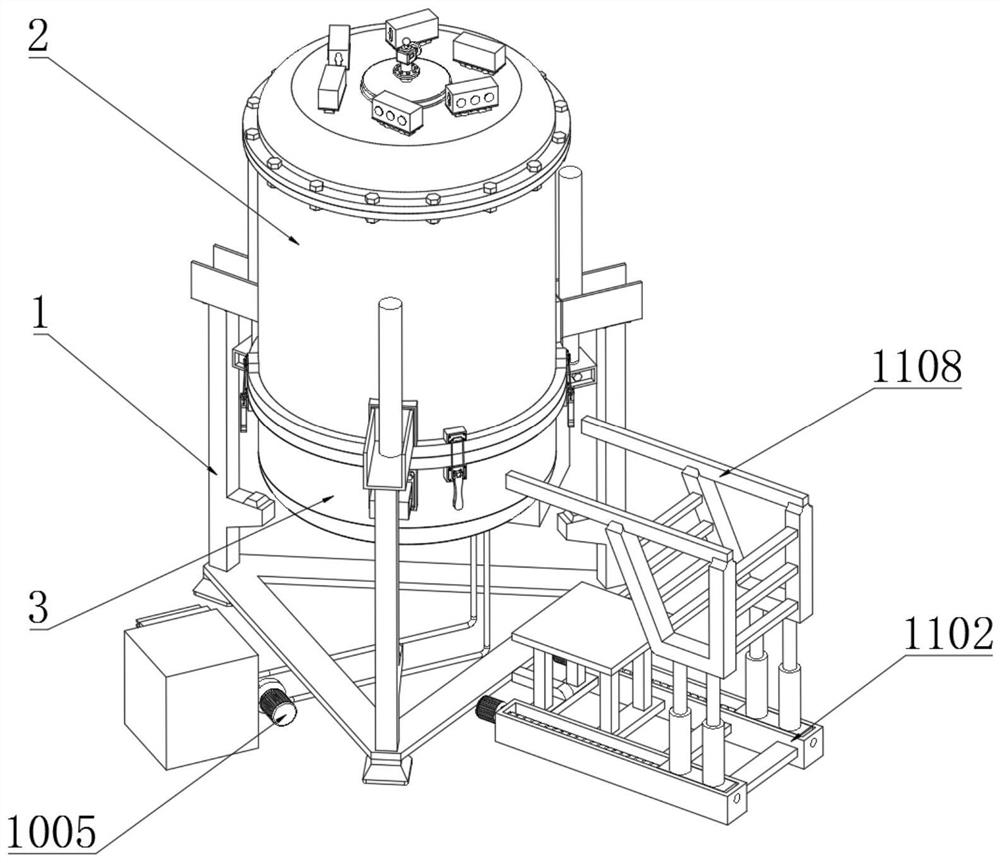

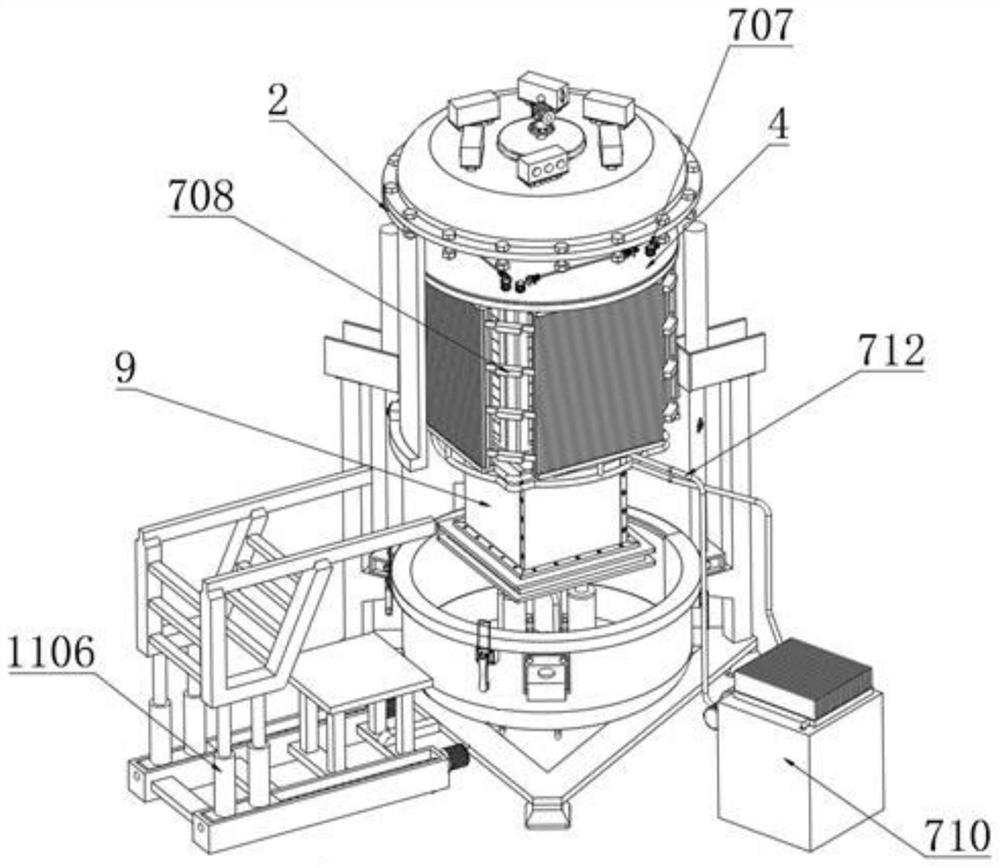

[0042] Example: such as Figure 1-12 As shown, the present invention provides a technical solution, a high-efficiency ingot casting furnace with heat balance, including a mounting bracket 1, the inner top of the mounting bracket 1 is fixedly connected with an upper furnace body 2, and the inner bottom end of the mounting bracket 1 corresponds to the upper furnace body 2. The lower furnace body 3 is movably connected to the bottom position through the lifting mechanism, and the installation plate 4 is fixedly connected to the top inside the upper furnace body 2. There is an installation cavity between the installation plate 4 and the inner top of the upper furnace body 2. The bottom of the installation plate 4 The end is fixedly connected with a thermal insulation board 5, and a graphite heater is installed in the middle of the bottom of the thermal insulation board 5;

[0043] The inside of the upper furnace body 2 is provided with a heating control mechanism 6 and a heat cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com