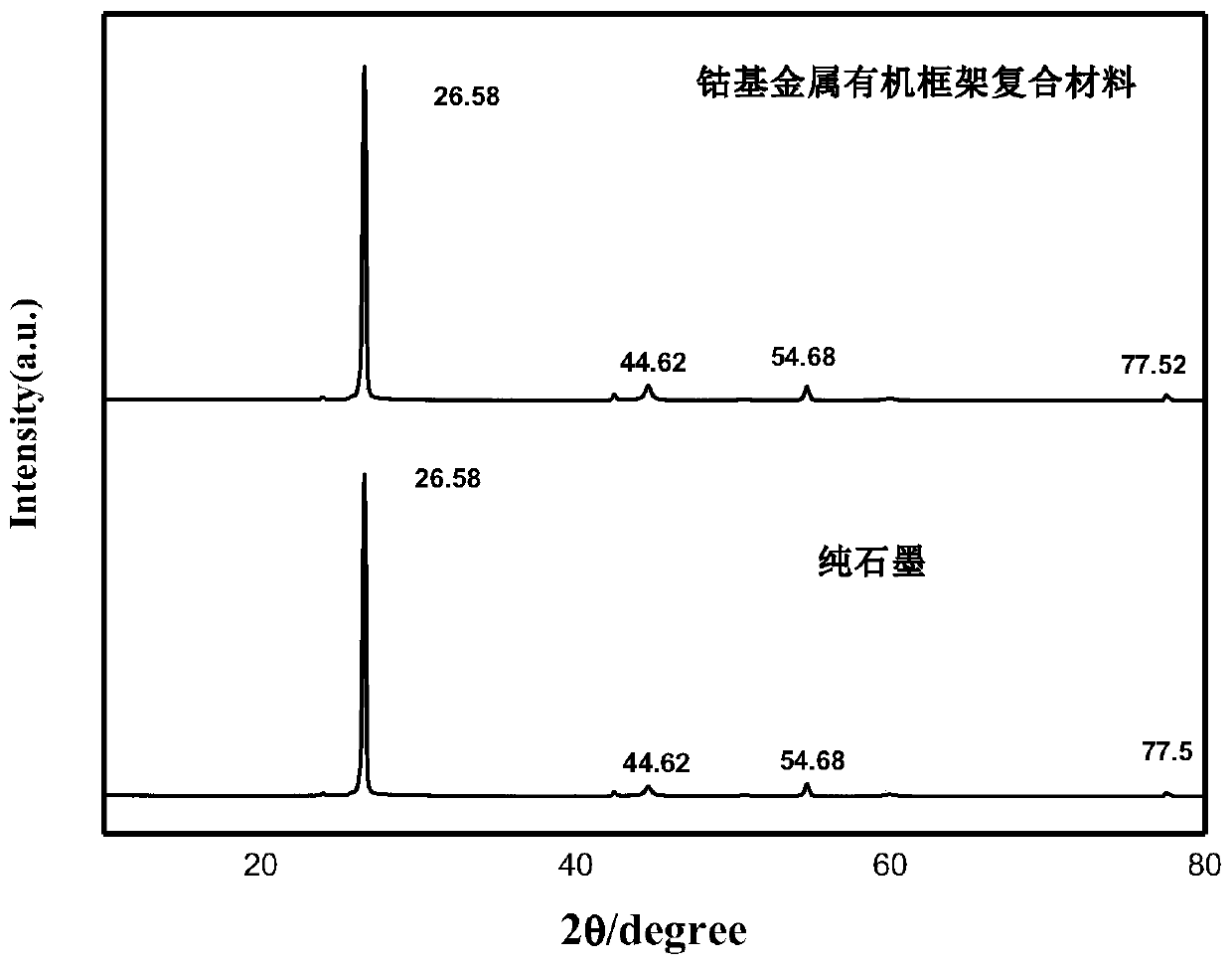

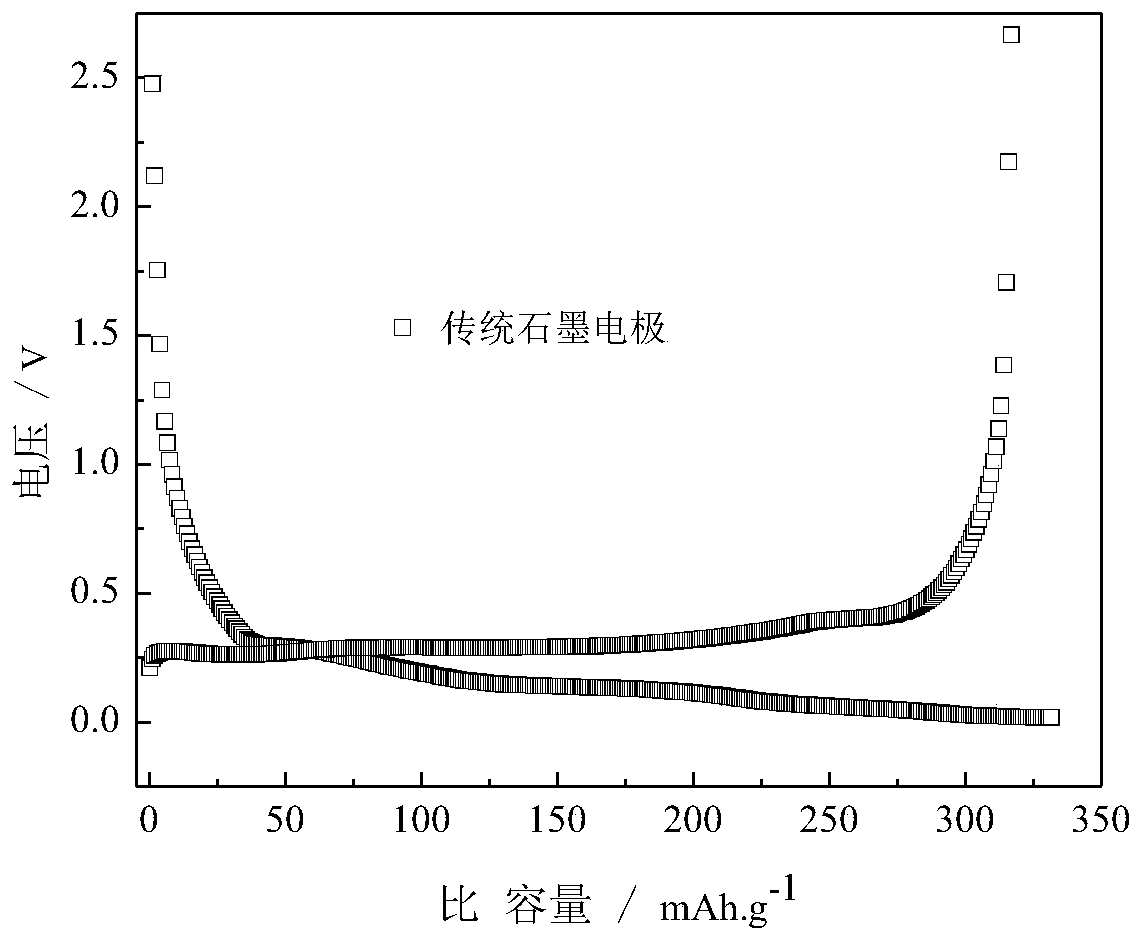

Preparation method and application of graphite and cobalt-based metal organic framework composite materials for negative electrode of lithium ion battery

A lithium-ion battery and organic framework technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of small layer spacing of graphite materials, affect battery cycle life, destroy conductive network, etc., and achieve simple preparation method and easy operation , Improve the effect of cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) 1mol cobalt acetate and 1.5mol organic matrix isophthalic acid are mixed evenly to obtain a cobalt acetate-organic matrix isophthalic acid mixture; the cobalt acetate-organic matrix isophthalic acid mixture and graphite are in a mass ratio of 1:20 Mix to obtain graphite mixture;

[0028] (2) Add 3mol N-N dimethylformamide to the graphite mixture, stir it evenly, pour it into a hydrothermal reaction kettle, heat it to 130°C, and heat it for 15 hours; after the reaction is completed, pour it out and wash it with distilled water, and settle to remove the upper layer The supernatant was kept, and the precipitate was washed repeatedly with distilled water for 3 times, then centrifuged at 6000r / min for 10 minutes, the supernatant was removed, and the precipitate was kept;

[0029] (3) Disperse the precipitate obtained after centrifugation under 240W ultrasonic conditions for 2.5 hours at room temperature; then dry at 80° C. for 12 hours and cool to obtain graphite and cob...

Embodiment 2

[0032] (1) 1mol cobalt acetate and 2mol organic matrix isophthalic acid are mixed uniformly to obtain a cobalt acetate-organic matrix isophthalic acid mixture; the cobalt acetate-organic matrix isophthalic acid mixture and graphite are combined according to a mass ratio of 1:20 , to obtain graphite mixture;

[0033] (2) Add 2mol N-N dimethylformamide to the graphite mixture, stir evenly, pour it into a hydrothermal reaction kettle, heat to 150°C, and heat for 18 hours;

[0034] (3) Take out the reactant in the hydrothermal reaction kettle, wash it with distilled water, settle and discard the supernatant, keep the sediment, wash it repeatedly with distilled water 4 times, then centrifuge at 4000r / min for 15 minutes, remove the supernatant , to retain the sediment;

[0035] (4) The precipitate obtained after centrifugation was dispersed under 240W ultrasonic conditions for 3 hours at room temperature, and then dried at 80° C. for 14 hours to obtain a composite material of graph...

Embodiment 3

[0037] (1) Mix 1mol cobalt acetate and 2.5mol organic matrix isophthalic acid evenly to obtain a cobalt acetate-organic matrix isophthalic acid mixture; mix cobalt acetate-organic matrix isophthalic acid mixture and graphite according to the mass ratio of 1:6 Mix to obtain graphite mixture;

[0038] (2) Add 4mol N-N dimethylformamide to the graphite mixture, stir evenly, pour it into a hydrothermal reaction kettle, heat to 180°C, and heat for 20 hours;

[0039] (3) The reactant in the hydrothermal reaction kettle was taken out, washed with absolute ethanol, settled and discarded the supernatant, retained the precipitate, washed repeatedly with absolute ethanol 5 times, then centrifuged at 7000r / min for 12 minutes, Remove the supernatant and keep the precipitate;

[0040] (4) The precipitate obtained after centrifugation was dispersed under 240W ultrasonic conditions for 3 hours at room temperature, and then dried at 80° C. for 14 hours to obtain a composite material of graphi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com