A kind of preparation method of silver-aluminum ferrocyanide nanomaterial with core-shell structure

A core-shell structure, potassium ferrocyanide technology, applied in the directions of ferricyanide, nanotechnology, metal cyanide, etc., can solve the problems of complex process steps, unfavorable and dangerous nanomaterials of core-shell structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

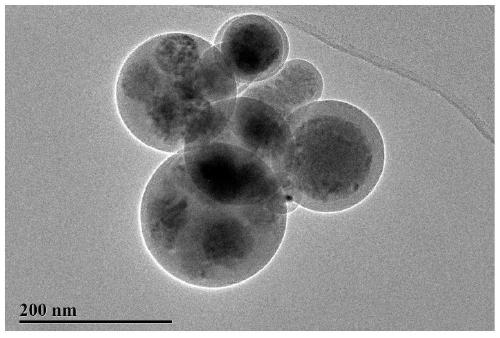

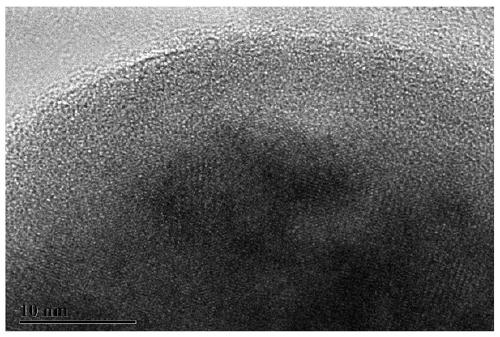

[0021] The invention provides a method for preparing a silver-aluminum ferrocyanide nanomaterial with a core-shell structure, comprising the following steps:

[0022] The silver nitrate solution and the aluminum chloride solution are dropped into the potassium ferrocyanide solution at the same time to carry out a co-precipitation reaction to obtain a core-shell structure silver aluminum ferrocyanide nanomaterial.

[0023] In the present invention, the purity of potassium ferrocyanide in the potassium ferrocyanide solution, silver nitrate in the silver nitrate solution, and aluminum chloride in the aluminum chloride solution is preferably no less than analytical purity. In the present invention, potassium ferrocyanide, silver nitrate and aluminum chloride are preferably dissolved in pure water to obtain potassium ferrocyanide solution, silver nitrate solution and aluminum chloride solution respectively. In the present invention, the concentrations of the potassium ferrocyanide ...

Embodiment 1

[0031] Dissolve analytically pure potassium ferrocyanide, silver nitrate and aluminum chloride (the molar ratio of potassium ferrocyanide, silver nitrate and aluminum chloride is 1:1:1) in purified water to obtain concentrations of 0.1 Potassium ferrocyanide solution, silver nitrate solution and aluminum chloride solution of mol / L; The potassium ferrocyanide solution is placed on the magnetic stirring device, carries out magnetic stirring (rotating speed 60rmp); The silver nitrate solution Drop into the potassium ferrocyanide solution at the same time as the aluminum chloride solution, the dropping rate is 0.05mL / s, carry out the co-precipitation reaction at 25°C until the three solutions are completely mixed, and the precipitation reaction is terminated; turn off the magnetic force Stir, the obtained mixed solution is taken out from the magnetic stirring device, and placed in an ultrasonic vibration cleaner for ultrasonic vibration dispersion for 30 minutes; the obtained dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com