Polyurethane curing agent and preparation process thereof

A technology of polyurethane curing agent and water agent, applied in the field of polyurethane curing agent and its preparation technology, can solve problems such as poor temperature resistance and overall quality reduction, and achieve the effects of improved stability, extended storage period and good curing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

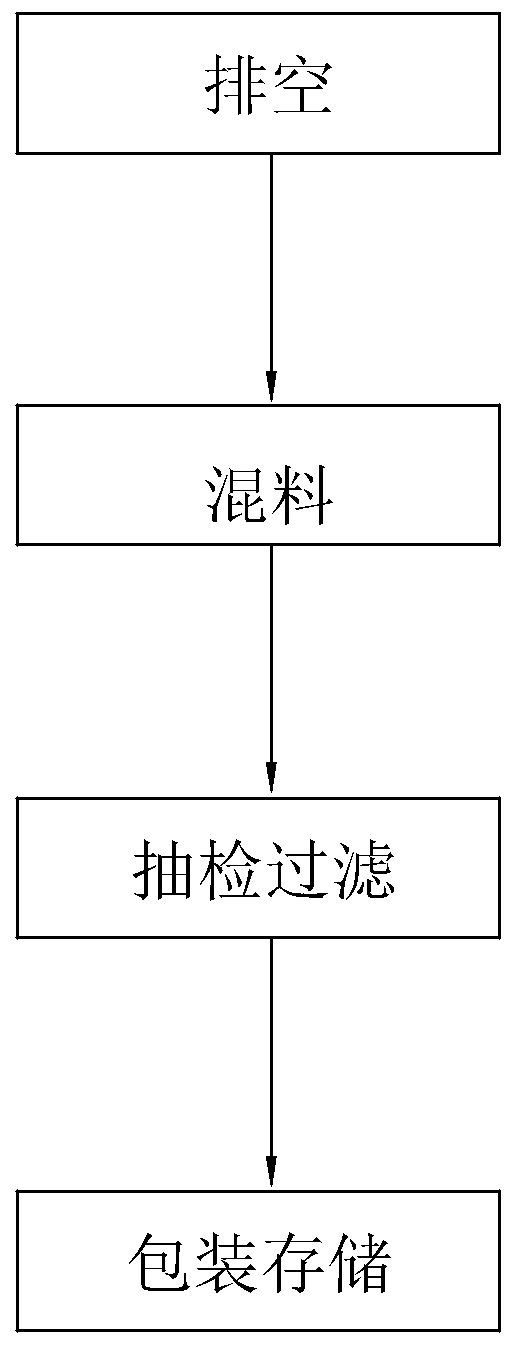

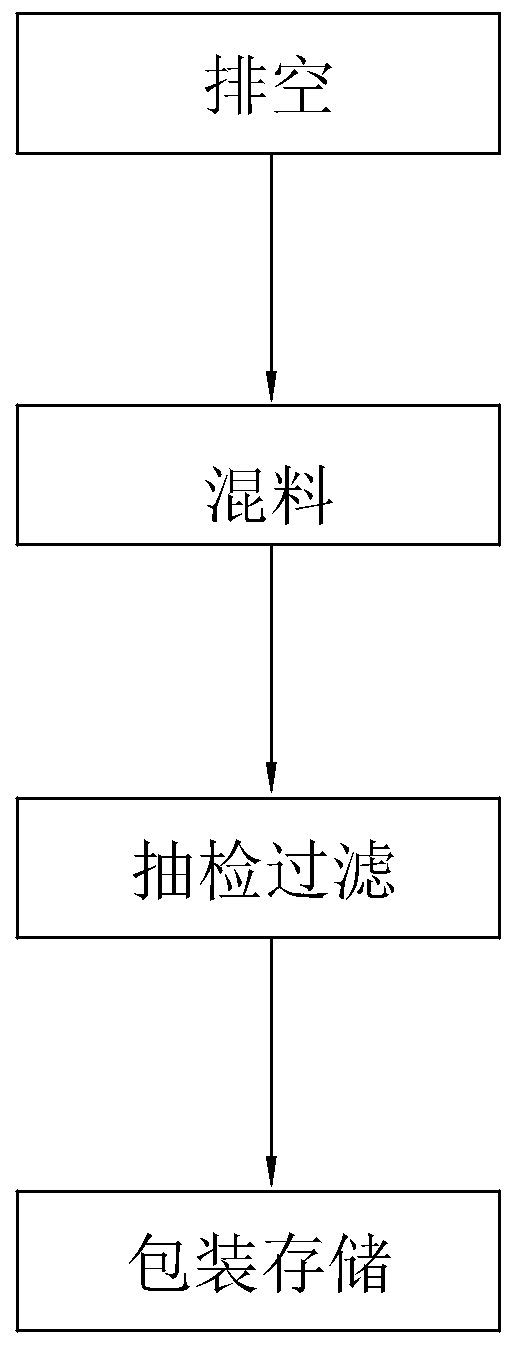

[0043] Embodiment 1: A polyurethane curing agent, each component and its corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0044] Step 1, emptying, filling the airtight stirred tank with nitrogen, and measuring the oxygen content at the bottom of the stirred tank with an oxygen meter, and the measured oxygen content is 0.93%;

[0045] Step 2, mixing materials, pass the corresponding parts by weight of DESMODUR N 3300, phosphite, ethyl acetate, dibutyltin dilaurate, biuret, methyl borate, tributyl phosphite and triethyl orthoformate The magnetic pump is transported to the stirred tank, and nitrogen is used for protection during the transport process, and then stirred and mixed evenly, the stirring speed is 600-800 rpm, and the time is 30 minutes to obtain the sample material;

[0046] Step 3: Sampling and filtering, testing the obtained sample materials, and passing the qualified sample materials through a filter for impurity re...

Embodiment 2-8

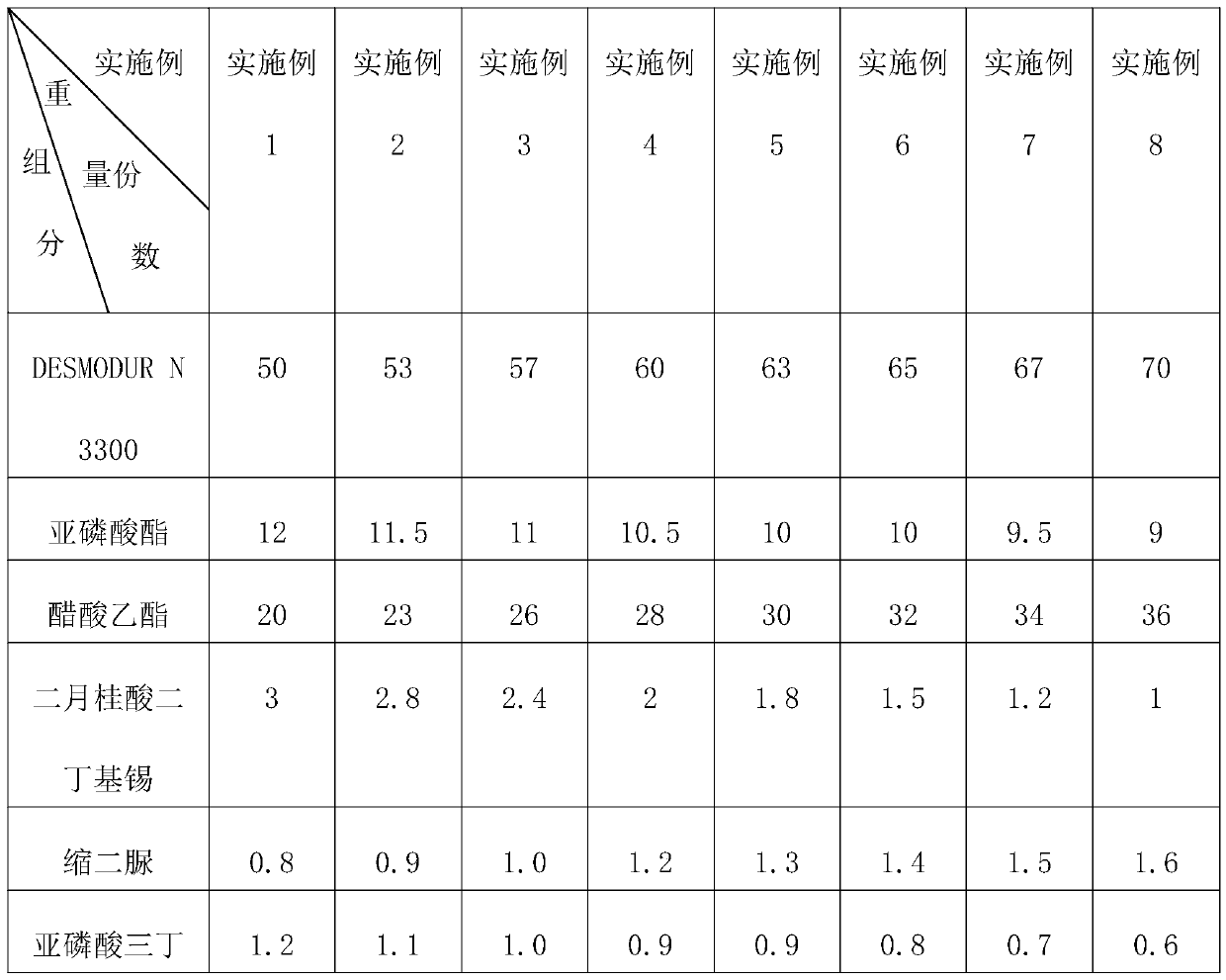

[0048] Example 2-8: A polyurethane curing agent, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0049] Each component and parts by weight thereof in table 1 embodiment 1-8

[0050]

[0051]

Embodiment 9

[0052] Embodiment 9: a polyurethane curing agent, the difference from Example 1 is that step 2 is specifically set as, mixing, the corresponding parts by weight are 50 parts of DESMODUR N 3300, 12 parts of phosphite, 20 parts Parts of ethyl acetate, 3 parts of dibutyltin dilaurate, 0.8 parts of biuret, 1.5 parts of methyl borate, 1.2 parts of zinc dialkyldithiocarbamate and 0.3 parts of triethyl orthoformate It was transported to a stirring tank by a magnetic pump, and nitrogen was used for protection during the transport process, and then stirred and mixed uniformly at a stirring speed of 600-800 rpm for 30 minutes to obtain a sample material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com