Mobile phone glass cover plate experiment platform

An experimental platform, glass cover technology, applied in the direction of material analysis, ion implantation, coating, etc. by optical means, can solve the problems of affecting the structure and performance of the film, low production efficiency, low vacuum, etc., and achieve low Cost-effective production, suitable for large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail and completely below in conjunction with Examples and Comparative Examples.

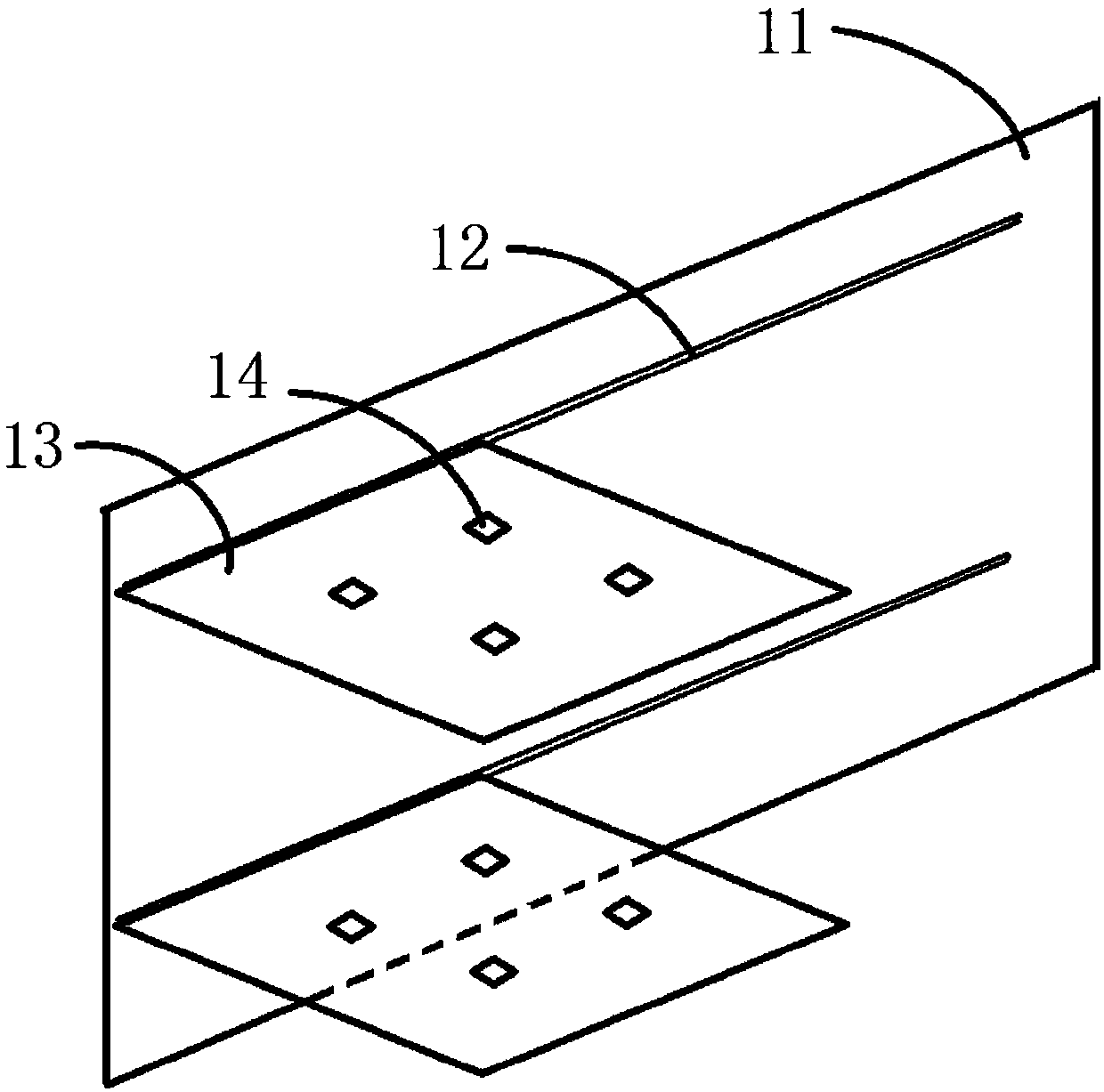

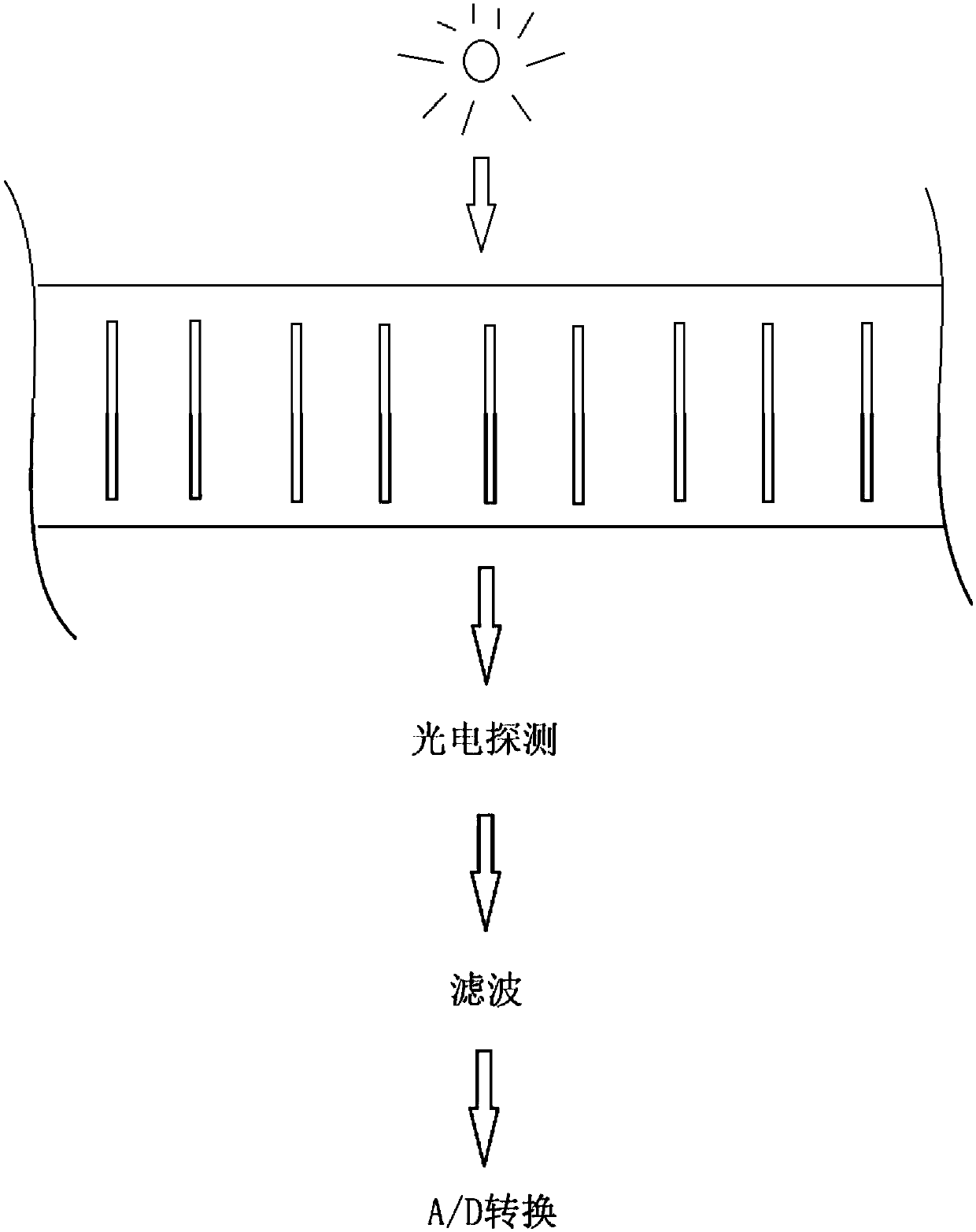

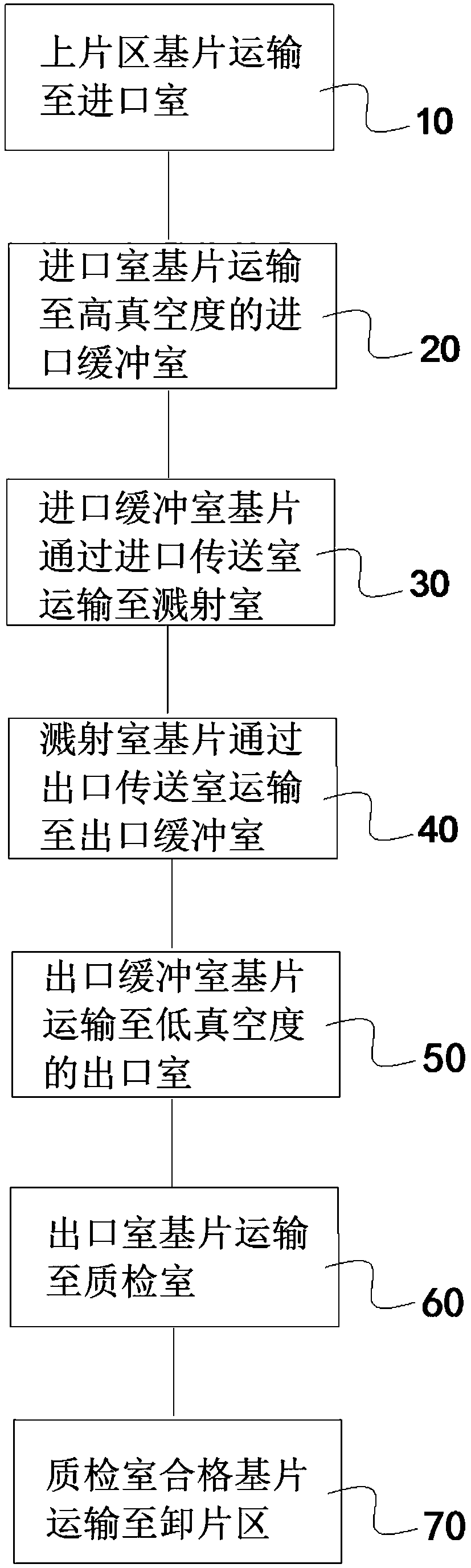

[0020] The mobile phone glass cover plate experimental platform of the present invention is installed in the quality inspection room of the vacuum coating production line. The processing and installation conditions are then determined and divided into several sections), the outlet transfer room, the outlet buffer room, the outlet room and the quality inspection room, and each process room is connected by a flap valve; figure 1 It can be seen that the process steps of production line preparation are: the substrate in the upper area is transported to the inlet chamber, the substrate in the inlet chamber is transported to the inlet buffer chamber with high vacuum, the substrate in the inlet buffer chamber is transported to the sputtering chamber through the inlet transfer chamber, the sputtering The substrates in the exit chamber are trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap