Assembly type prefabricated high-strength concrete floor tile system and construction method thereof

A technology of high-strength concrete and floor tiles, applied in floors, buildings, building structures, etc., can solve the problems of heavy floor load, difficulty in finding fault points, unfavorable maintenance and secondary decoration, etc., to reduce production and installation costs, The effect of increasing safety and reliability and improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] An assembled prefabricated high-strength concrete floor brick system comprises an assembled prefabricated high-strength concrete floor brick and an assembled prefabricated high-strength concrete floor brick support structure matched and connected therewith.

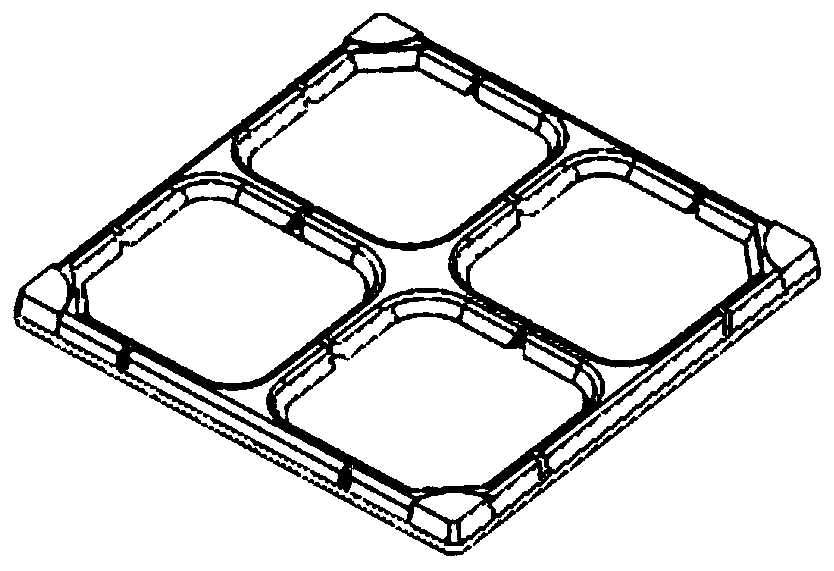

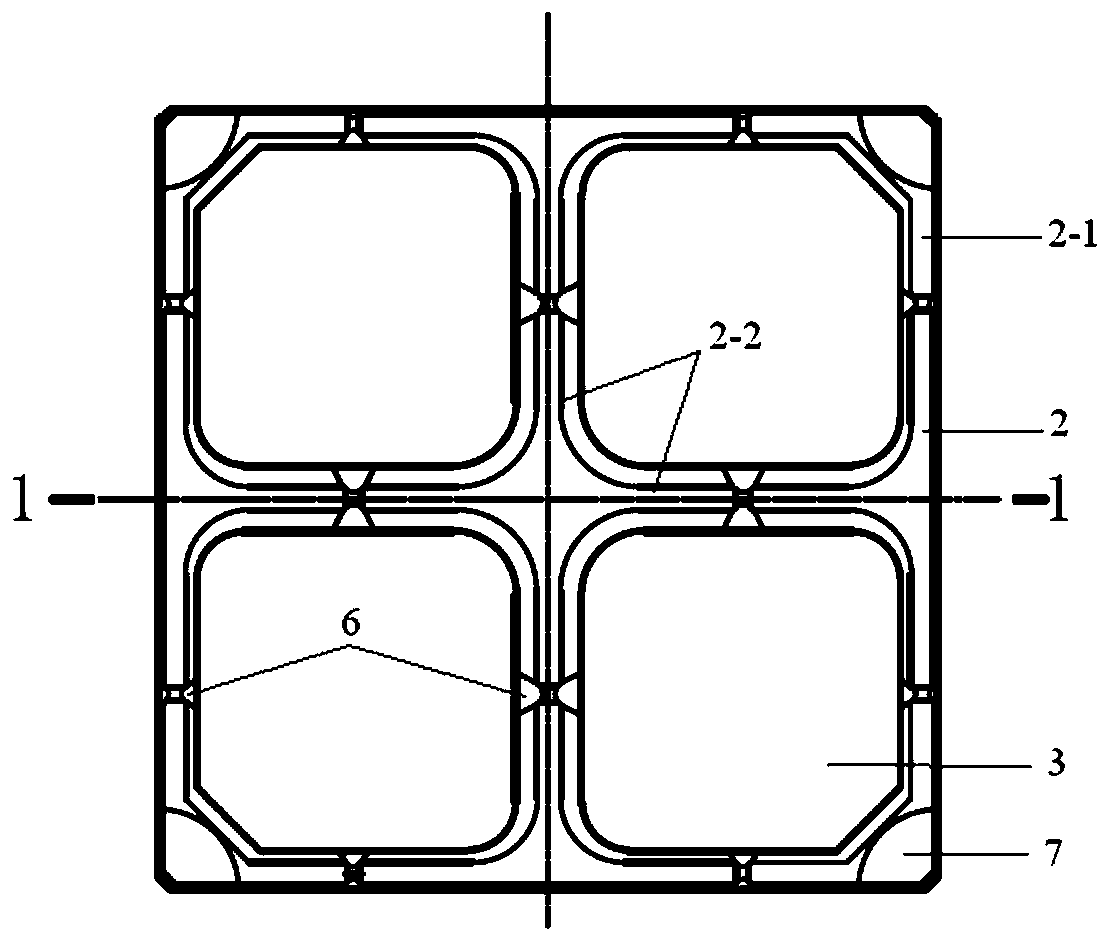

[0050] Such as Figure 1-2 As shown, the prefabricated prefabricated high-strength concrete floor tiles include the front surface layer and the back concrete reinforcement rib structure stress layer connected integrally with it, such as Figure 3-5 As shown, the concrete structure stress layer includes a concrete plane layer 1, a rib stress structure 2 connected to the lower part of the concrete plane 1, a structural groove 3 separated by the rib stress structure 2 and steel reinforcements, The steel reinforcements include stressed steel bars 4 penetrating and connected in the rib stress structure and steel plate mesh sheets 5 penetrating and connected in the concrete plane layer, and the middle part of the rib str...

Embodiment 2

[0063] A construction method for an assembled prefabricated high-strength concrete floor tile system described in Example 1, comprising the following steps:

[0064] S1. Install the reinforced steel bar 4 and the steel plate mesh 5 in turn on the special mold for the floor tile, and add 0.9kg / m³ anti-crack fiber material to the concrete to ensure that the concrete does not crack;

[0065] S2. After pouring, use a plate vibrator to vibrate, form, demould, and steam cure for 24 hours to form a relatively high-strength concrete floor tile. The thickness of the floor tile surface and reinforcing ribs is 15mm. The reinforced rib structure with a height of 15mm is used to reduce the weight of the ground brick to 7.5kg, and the bearing capacity of the brick body is as high as 2.5kN / ㎡;

[0066] S3. The support surface 7 at the four corners of the floor tiles has been polished to an installation accuracy of ±1.0mm;

[0067] S4. The standard adjustable support for installing the floor ...

Embodiment 3

[0073] The structure of each part of a prefabricated prefabricated high-strength concrete floor tile system described in this embodiment is the same as that in Embodiment 1, and the construction method is also the same, the differences are:

[0074] Such as Figure 15-18 As shown, the support structure described in this embodiment is an adjustable support for supporting and installing floor tiles at the inner corner of the wall. The bottom plate 8-1 and the support plate 9-1 of the adjustable support of the inner corner of the wall are both square in shape, and the internally threaded bolt hole 8-2 of the cylindrical support seat 8-4 communicates with the screw rod of the cylindrical connecting hole seat 9-4 The holes 9-4 are respectively located at the same corner position of the bottom plate 8-1 and the support plate 9-1, and the axes of the holes of the upper and lower holes are on the same axis; the support ribs 8-3 are three, two short The ribs are respectively connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com