Continuous microwave paper straw rolling drying and sterilizing equipment and working method thereof

A technology of sterilization equipment and suction pipes, which is applied in the direction of progressive dryers, drying solid materials, lighting and heating equipment, etc., can solve the problems of drying dead angle, fast evaporation of external water, slow internal evaporation, etc., to achieve speed increase and reduce drying. Dry corners, even absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

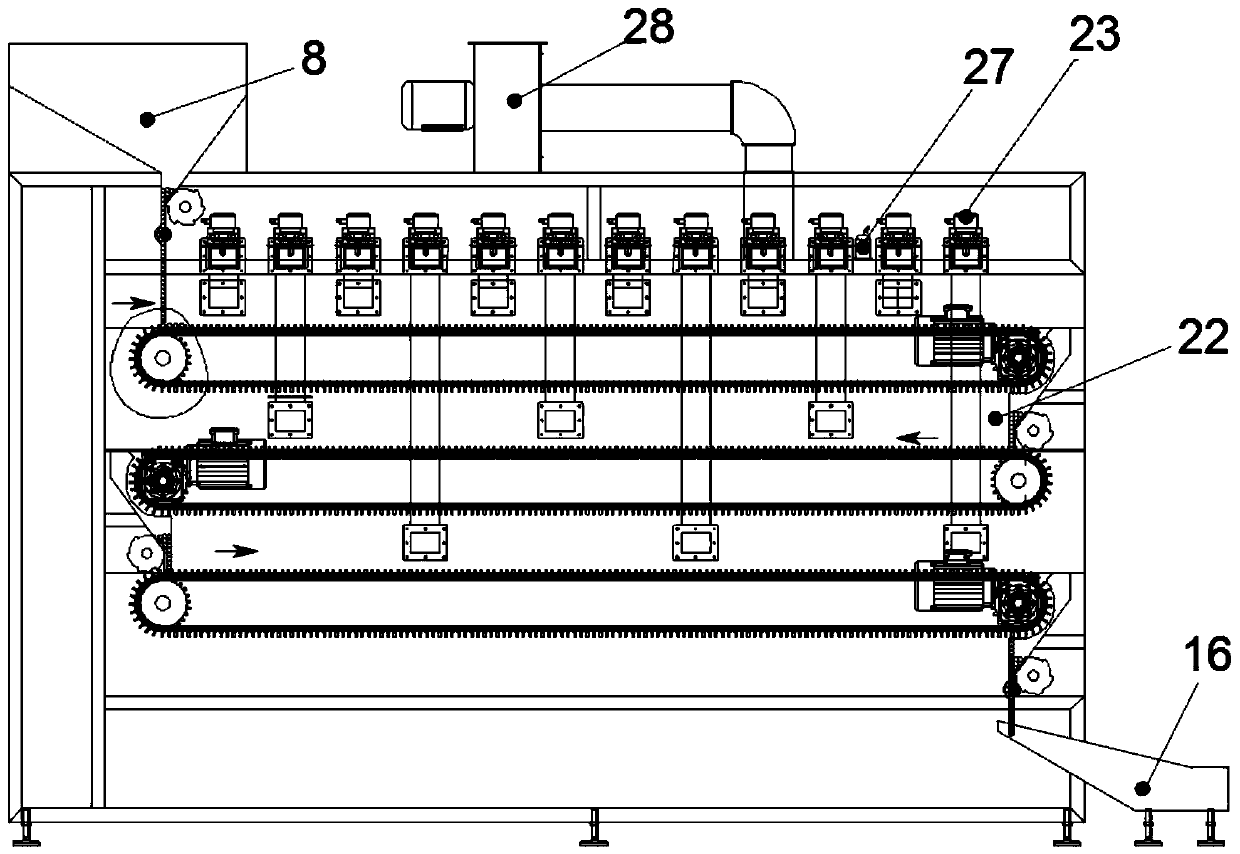

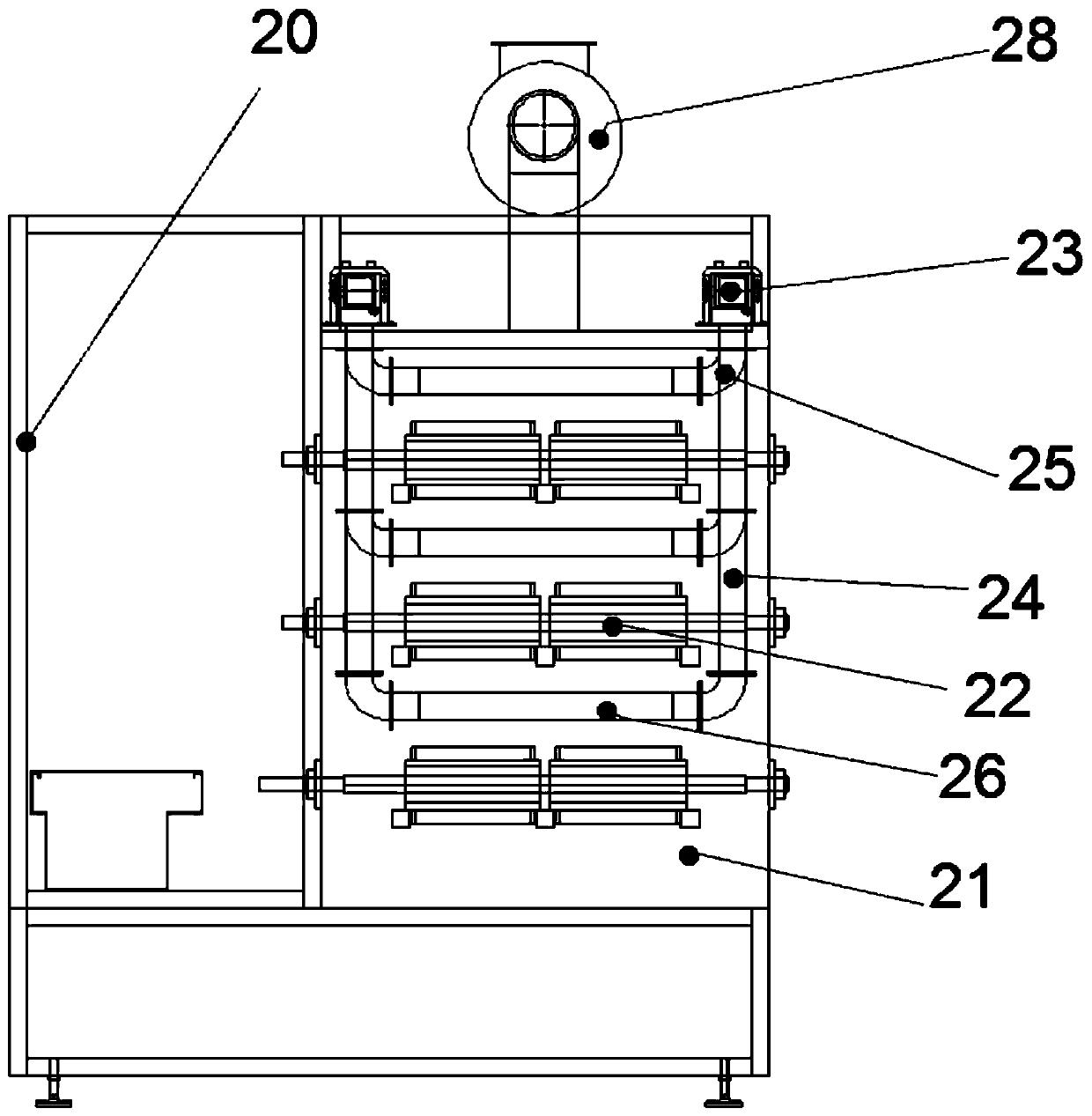

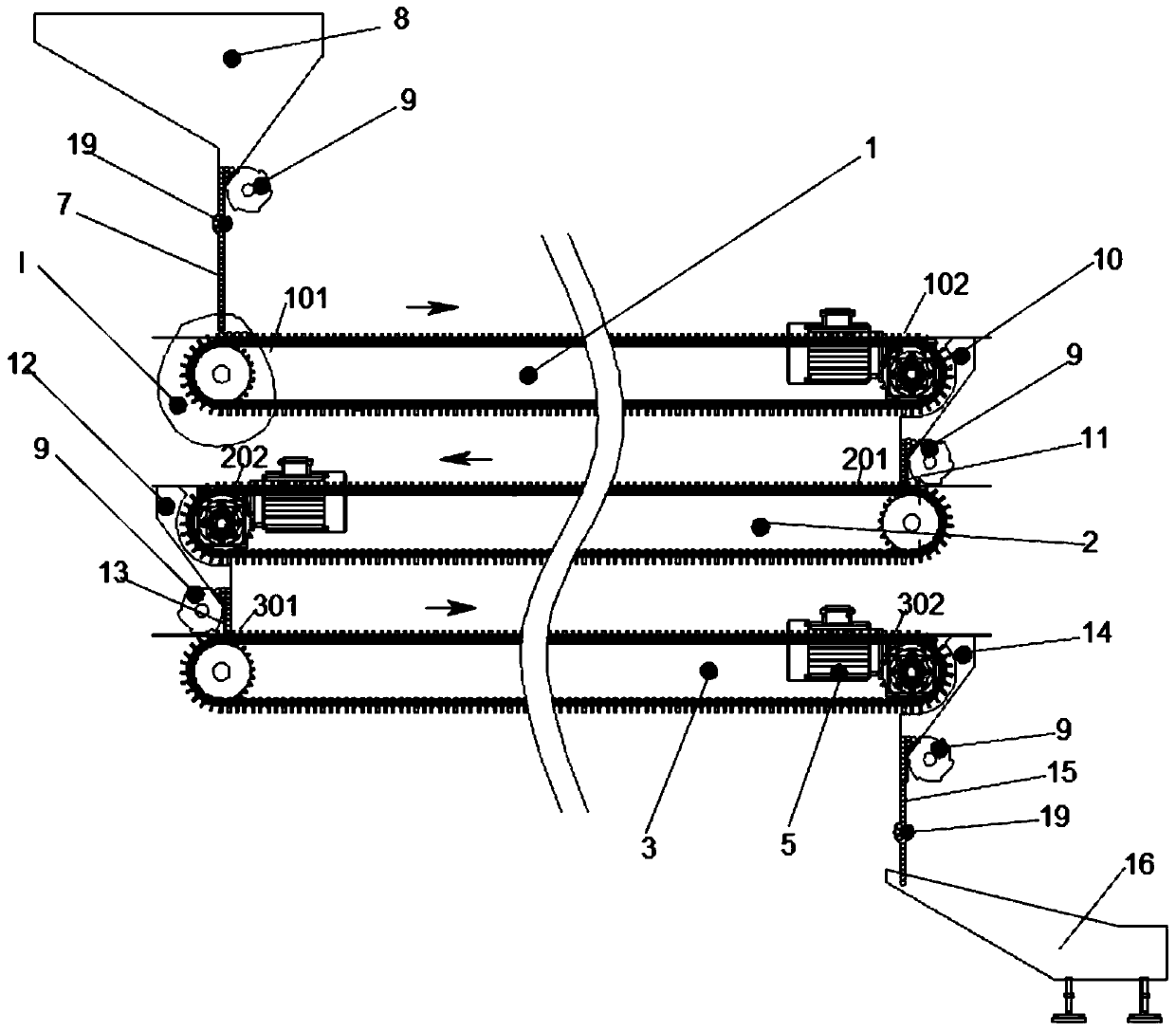

[0039] like Figures 1 to 10 As shown, a continuous microwave paper straw rolling drying and sterilization equipment includes a box body 20, the box body 20 includes a drying chamber 21, a paper straw conveying device 22 is arranged in the drying chamber 21, and twelve microwave emitting tubes are arranged above the drying chamber 21. The device 23, the paper straw conveying device 22 at least includes three layers of conveyor chains 4 arranged in parallel in the longitudinal direction. The socketed chain root 41 and the conveying chain driving lever 42, the conveying chain driving lever 42 is elongated, used to separate the paper straws, and the accommod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com