Test method of water content in slurry

A test method and technology for water content, which are applied in measuring devices, analyzing materials, and material analysis by electromagnetic means, etc., can solve the problems of slurry composition pollution, high slurry viscosity and difficult to test, and achieve the effect of simple testing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

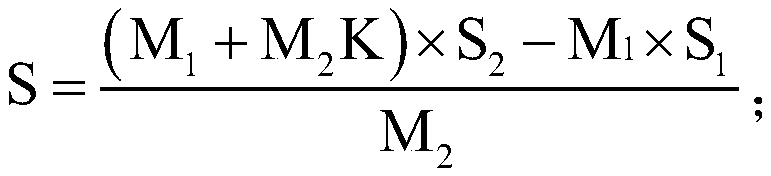

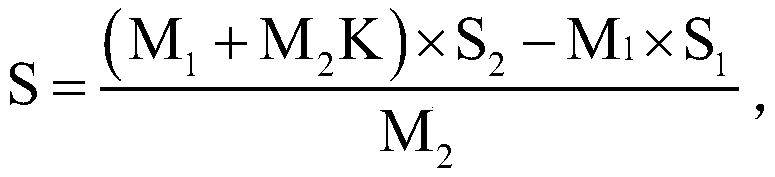

[0059] The recovery rate of extractant to the moisture in the slurry in the extraction process has obvious impact on the test accuracy of the method of the present invention, below is to verify the feasibility of the method of the present invention, a certain amount of pure water is added to blank ethyl acetate Among esters, test the recovery rate of ethyl acetate to water, thereby confirming that the present invention adopts ethyl acetate as the method for extraction agent is feasible, and its specific steps are as follows: the water content in the mixed solution after the present embodiment controls extraction is 330-15000 μ g / g;

[0060] (1) Take the mass as m 1 Ethyl acetate, using K-F moisture tester to test its relative water content s 1 ;

[0061] (2) Take the mass as m 2 pure water;

[0062] (3) Add the pure water in step (2) to the ethyl acetate in step (1) to obtain the mixed solution, stir it magnetically for 30 minutes, and then centrifuge it at 3000 rpm / min f...

Embodiment 2

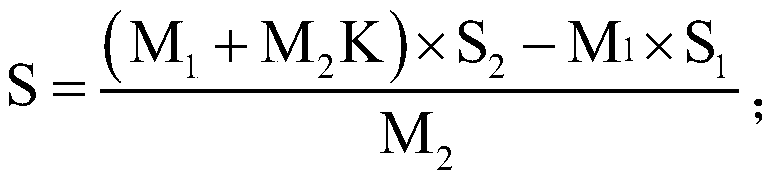

[0074] In this embodiment, the test capability of the method of the present invention is verified by repeatedly testing the same carbon nanotube slurry. The carbon nanotube slurry used in this embodiment contains conductive carbon, NMP solvent and trace water. Specific steps are as follows:

[0075] (1) Equipment drying, put the centrifuge tubes, magnets, syringes, etc. required for the test in the oven to dry for later use;

[0076] (2) Ethyl acetate dehydration: The analytically pure ethyl acetate required for the test is dehydrated with dry molecular sieves for 48 hours until its relative water content is below 50 μg / g;

[0077] (3) Weigh about 30 g of ethyl acetate into centrifuge tube A in a drying room (dew point < -40°C), add magnets, and use it as a blank sample;

[0078] (4) In a drying room (dew point 1 ) and about 5g of carbon nanotube slurry (its actual mass is denoted as M 2 ) to the centrifuge tube B, add magnets;

[0079] (5) After sealing the centrifuge tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com