Electrochemical lithium precipitation analysis method and module device thereof

An analysis method and electrochemical technology, applied in the direction of material analysis, measuring devices, and analysis materials through electromagnetic means, can solve the problems of manpower and material resources, low efficiency of lithium analysis, toxic and harmful detection sensitivity, etc., to avoid manpower and material resources , large application prospects and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

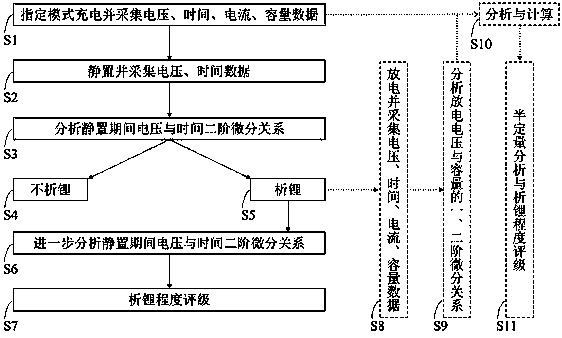

[0042] refer to figure 1 , the embodiment of the present invention proposes an electrochemical lithium analysis method, comprising the following steps:

[0043] S1, specify charging mode and collect voltage, time, current, capacity data. Among them, charging in the specified mode is: charging the lithium-ion battery to a certain voltage or to a certain state of charge (SOC) at a certain temperature and at a certain current under constant current or constant current and constant voltage.

[0044] S2, standing still and collecting voltage and time data.

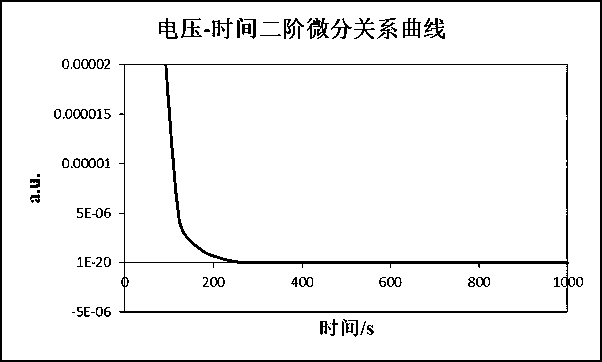

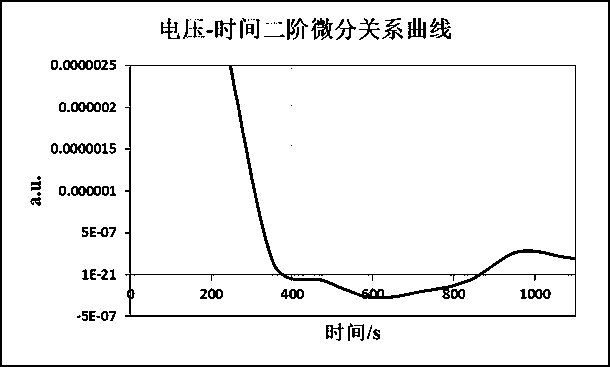

[0045] S3, analyzing the second-order differential relationship between voltage and time during the standing period.

[0046] S4, if the voltage-time curve collected in S3 is analyzed, and the second-order differential value of the voltage versus time does not appear to be less than zero at the initial stage of standing, it is determined that lithium is not separated.

[0047] S5, if the voltage-time curve collected in S3 is a...

Embodiment 2

[0068] refer to Figure 7 , the present invention provides a modular device based on the electrochemical lithium analysis method proposed above, including:

[0069] The first command unit is used to command the conditions and result output form of lithium analysis detection;

[0070] a first obtaining unit, configured to obtain the instruction;

[0071] The second acquisition unit is used to acquire the voltage, time, current, and capacity data of the charging process, and the voltage and time data of the resting process;

[0072] A third acquisition unit, configured to acquire a relationship curve between voltage and time during the standing process, and acquire the relationship between the second order differential of voltage versus time and time;

[0073] The judging unit is used for judging whether the battery has undergone lithium deposition according to the change of the second-order differential value of the voltage versus time, and gives an output result of "lithium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com