Wet etching equipment and photoresist cleaning and developing device

A wet etching and equipment technology, applied in the field of MEMS, can solve the problems of fine structure fracture and breakage, achieve the effect of strong corrosion resistance, improve etching uniformity, and meet the requirements of etching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

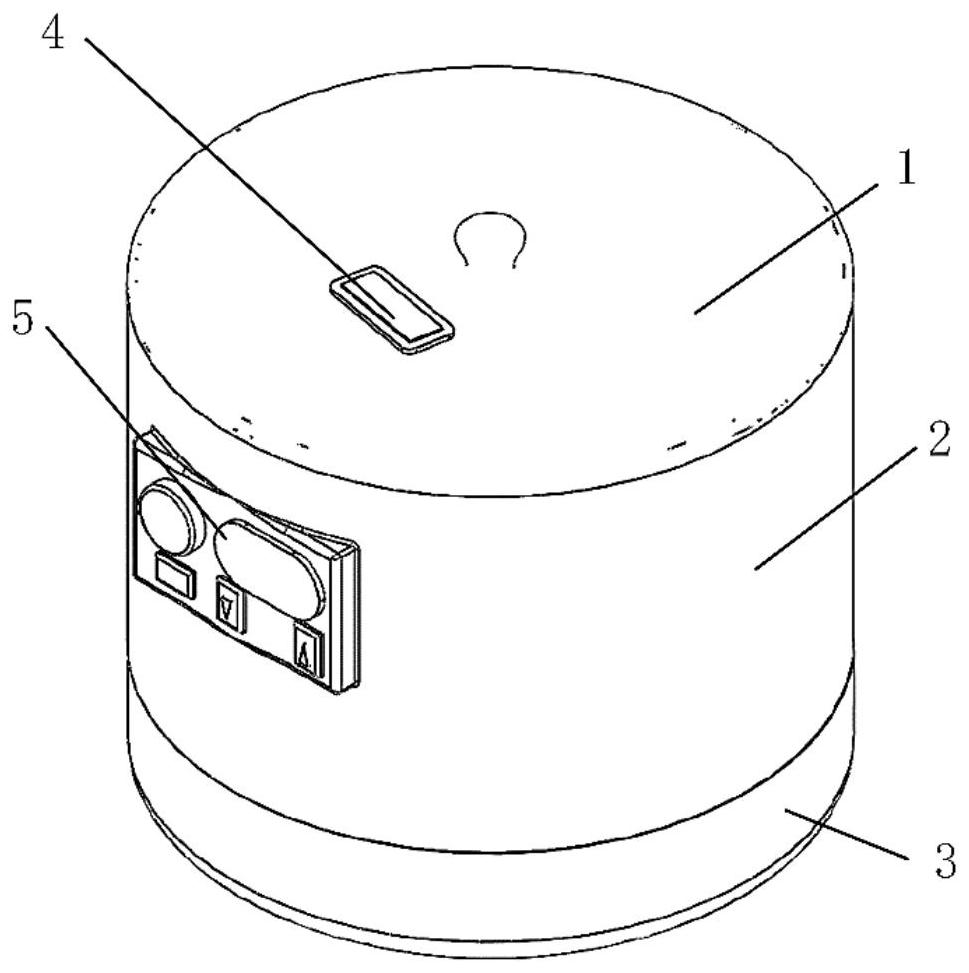

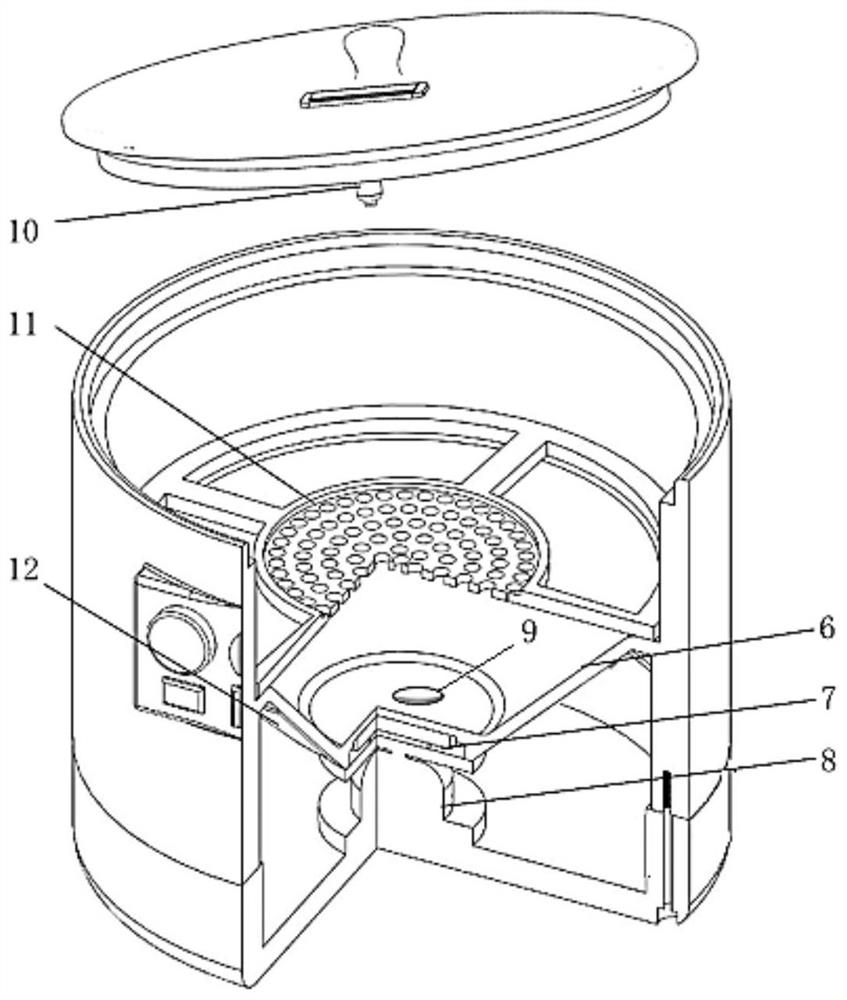

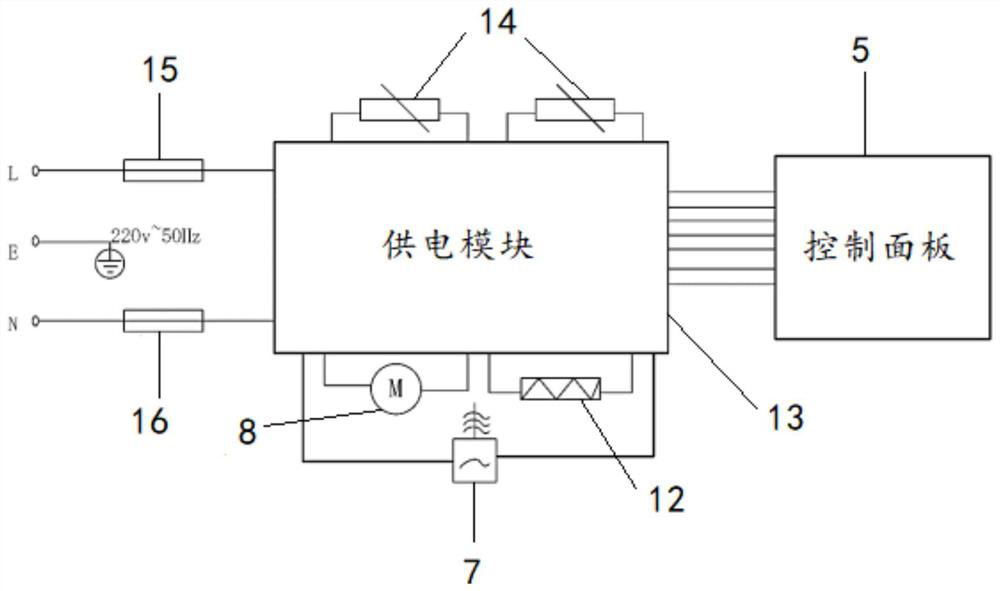

[0038] Such as figure 1 and 2 As shown, the wet etching equipment provided by the present invention includes: a housing, a control panel 5 is arranged on the outer wall of the housing; a liquid carrier basin 6 is arranged in the housing for holding a solution; The edge of the basin is fixedly connected with the inner wall of the housing; the ultrasonic atomizer 7 is fixed on the bottom of the liquid-carrying basin 6, and is used to atomize the solution in the liquid-carrying basin 6 into droplets; the etching flower basket 11 is arranged on the carrying On the basin edge of the liquid basin 6, it is used to hold the etched device; the etched device is separated from the solution; the power supply module 13 is arranged at the bottom of the housing; wherein, the ultrasonic atomizer 7 is electrically connected to the control panel 5 ; The ultrasonic atomizer 7 and the control panel 5 are electrically connected to the power supply module 13 .

[0039] The wet etching equipment o...

Embodiment 2

[0048] The present invention also provides a photoresist cleaning and developing device, including the wet etching equipment in the first embodiment above.

[0049] Specifically, the photoresist cleaning and developing device is used for the development process after traditional photolithography exposure. The photoresist developing solution is poured into the liquid carrier basin 6 and immersed in the device to be developed. If necessary, the electric heating patch can be adjusted. 12 Heating the developing solution without installing the etching flower basket 11 and opening the ultrasonic atomizer 7 .

[0050] The photoresist cleaning and developing device uses the post-exposure drying process. If the photoresist has a small adhesive force to the substrate and the traditional developing method of the photoresist surface has a large internal stress, it is easy to cause the photoresist to fall off and crack when it is etched. As described in Embodiment 1, it is necessary to ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com