Automatically controlled explosion-proof and dust-proof hot and cold difunctional vacuum kneader big cover

A vacuum kneader, dual-function technology, used in mixers, mixer accessories, dissolving and other directions, can solve the problems of dust generation, mixing cylinder explosion, etc., and achieve the effects of reducing friction, reducing exhaust gas emissions, and improving air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

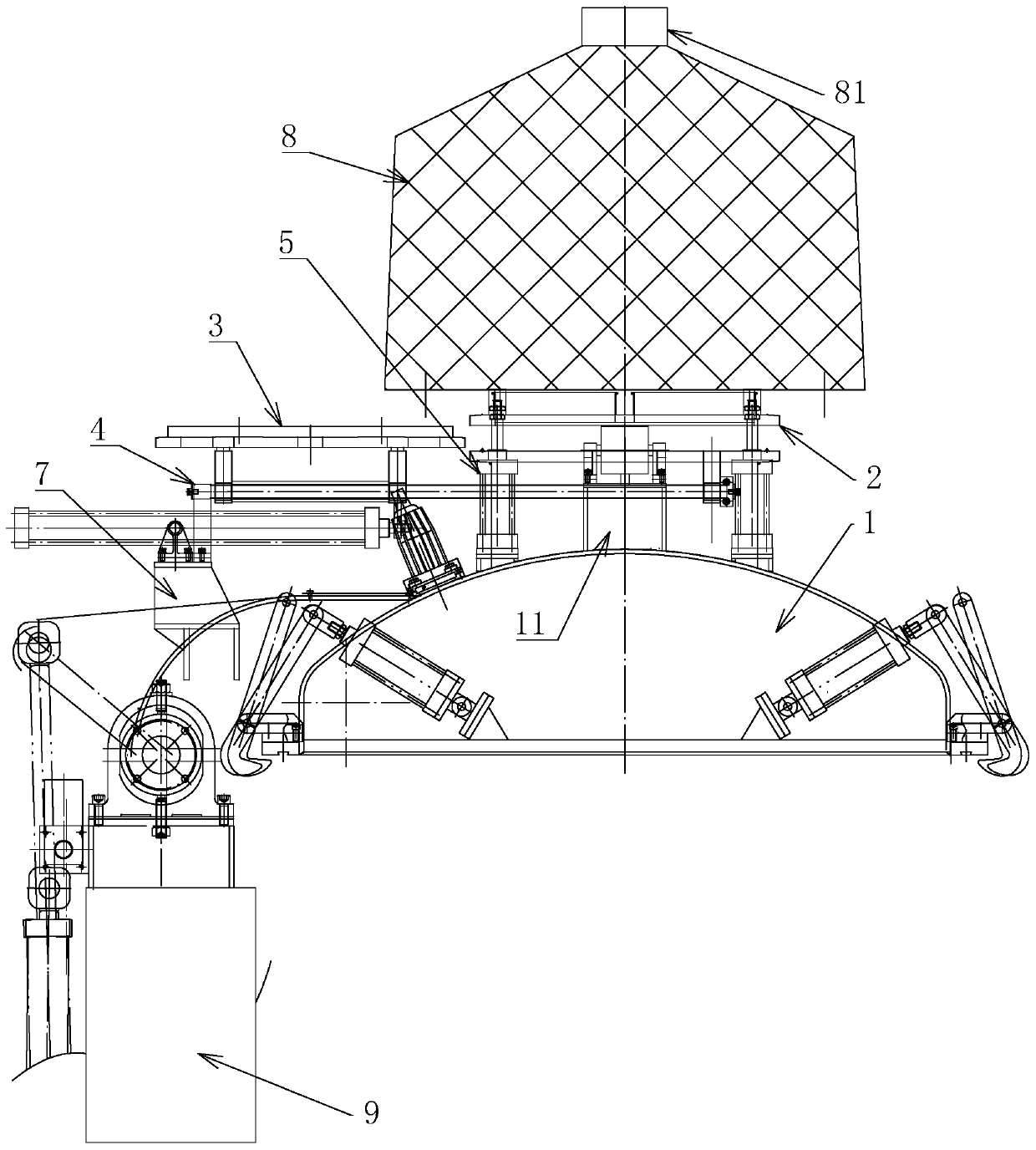

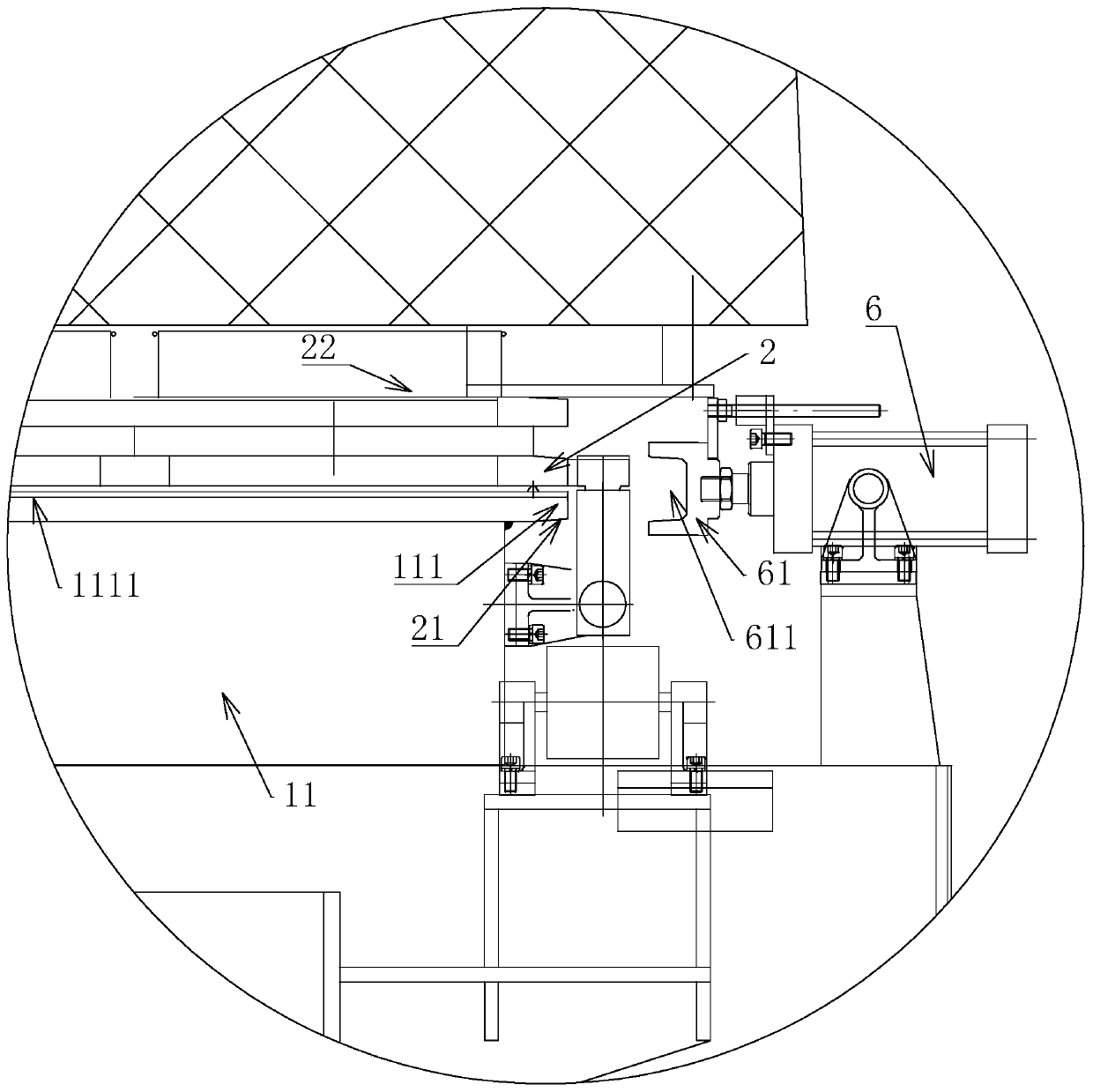

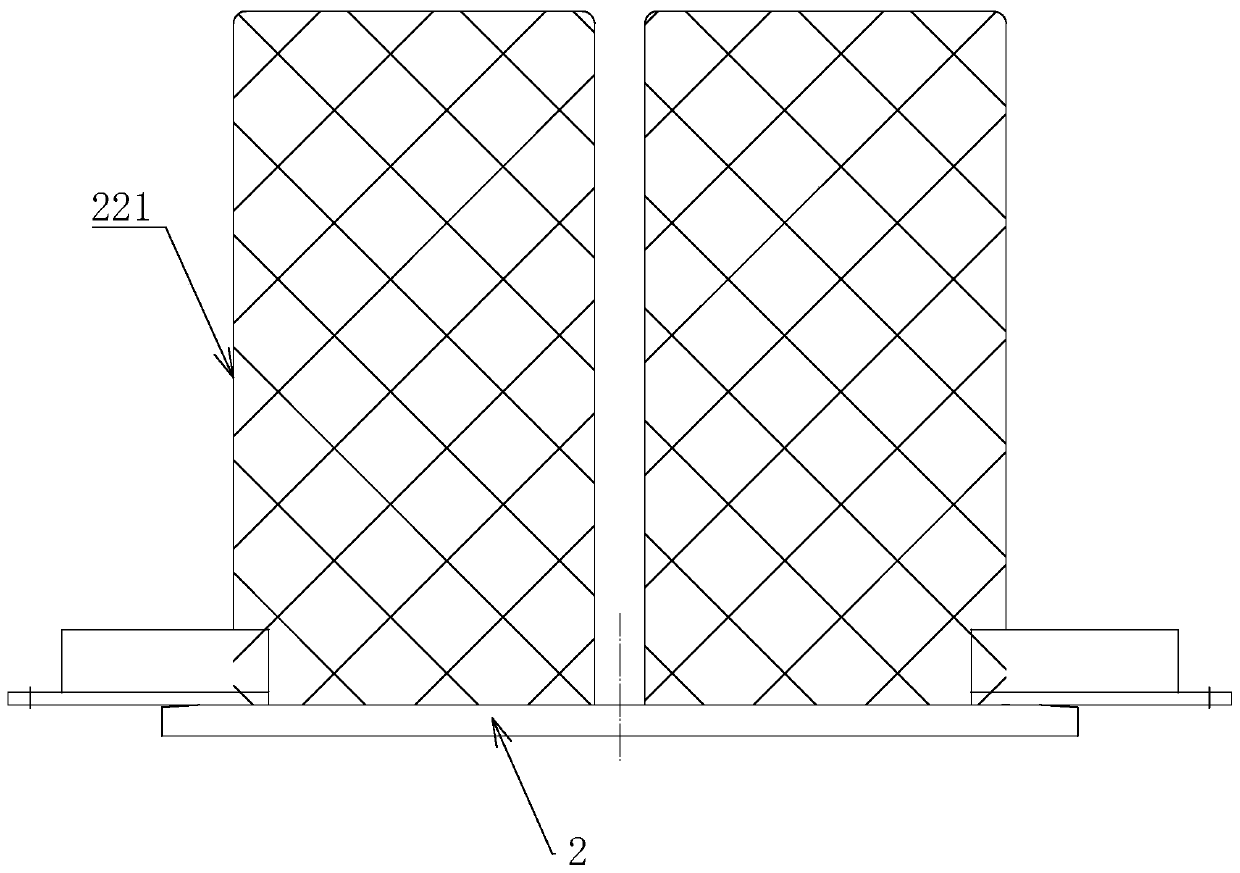

[0039] An automatic control explosion-proof dust-proof cold and hot dual-function vacuum kneader large cover, refer to figure 1 , which includes a large cover 1, the large cover 1 is provided with a channel 11, the channel 11 is a round tube or a square tube, and the channel 11 runs through the entire large cover 1. Both sides of the side wall of the channel 11 are respectively provided with a bag cover moving mechanism 5, the bag cover moving mechanism 5 is preferably an oil cylinder or an air cylinder, and there are four bag cover moving mechanisms 5, which are respectively located at the four corners of the channel 11. The end of the bag cover moving mechanism 5 away from the big cover 1 is provided with a bag cover 2, the bag cover 2 is a square metal plate, and a through hole is opened on the bag cover 2, and the piston rod of the bag cover moving mechanism 5 is fixed on the bag cover 2 near the big cover. Cover 1 surface.

[0040] refer to figure 1 , the side of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com