Forging and forming method of two-piece flange connection ball valve cover blank

A connecting ball and two-piece technology, applied in the direction of valve devices, metal processing equipment, etc., can solve the problems of easy bending of the workpiece, poor stability of the workpiece, and unreasonable design, so as to improve the forging coaxiality and high coaxiality , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

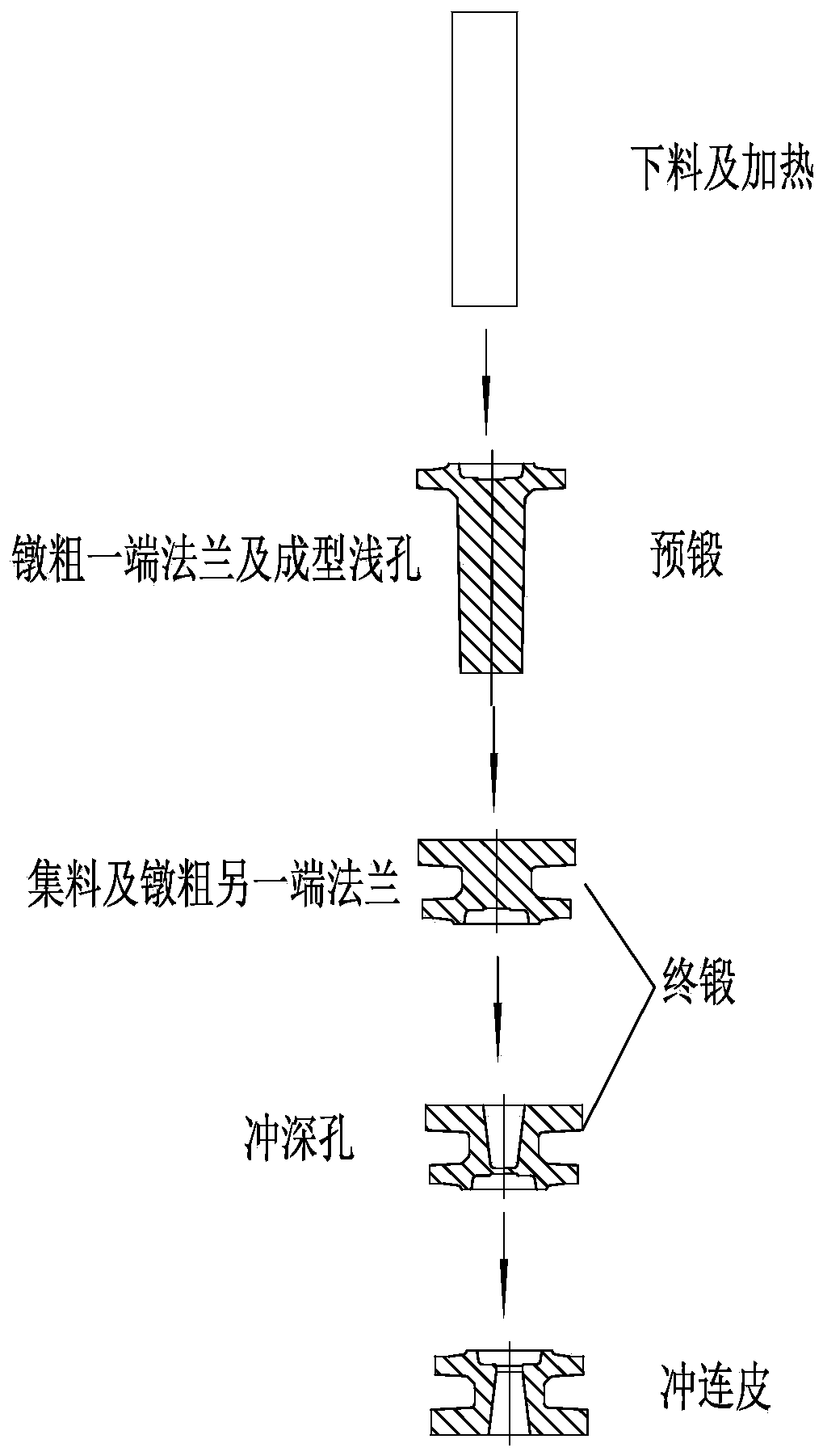

[0033] Such as figure 2 Shown, a kind of two-piece flange connection ball valve bonnet blank forging forming method comprises the following steps:

[0034] The first step: blanking, heating to forging temperature;

[0035] In the first step, it is best to use a band saw to cut the bar to ensure that the saw seam is straight; use an induction heater to heat it to 1150 ° C ~ 1250 ° C with natural gas as fuel.

[0036] Step 2: Form one end flange and shallow hole in the pre-forging die.

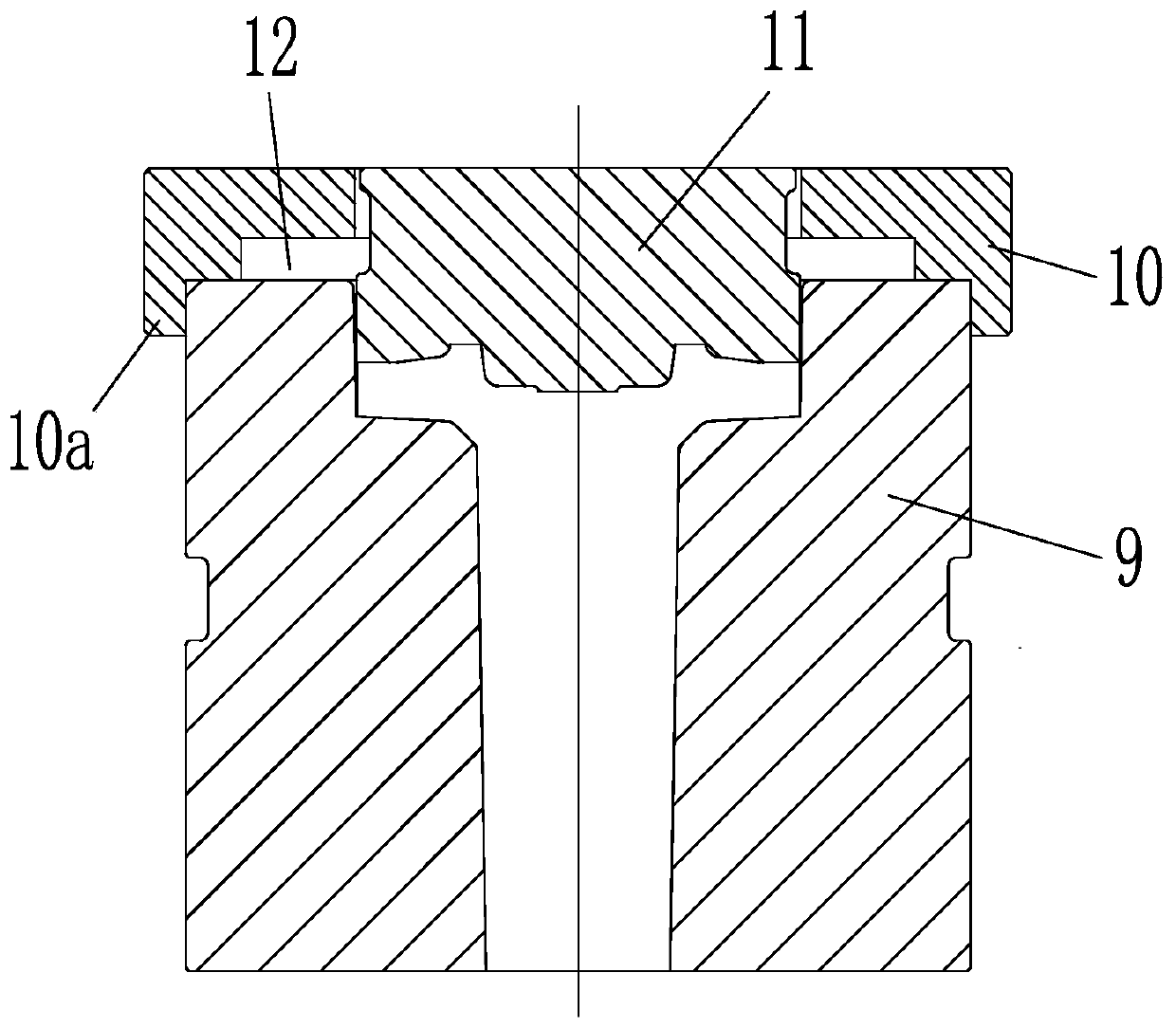

[0037] Such as image 3 As shown, the blocker is mainly composed of the lower blocker die 9, the centering sleeve 10 and the first punch 11.

[0038] The lower pre-forging die 9 has a vertically through "T" cavity, and the centering sleeve 10 and the first punch 11 are arranged coaxially with the lower pre-forging die 9 . The bottom of the centering sleeve 10 has a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com