Production line for refining and purifying crude gold, crude gold pulverization device and spraying pipe

A spray pipe and chemical device technology, applied in the field of spray pipe, can solve the problems of high price and difficulty in equipping, and achieve the effects of low cost, avoiding excessive nitrogen oxides in exhaust gas, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following describes the present invention in detail through specific embodiments in combination with the drawings. It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict, and the protection scope of the present invention is not limited to this.

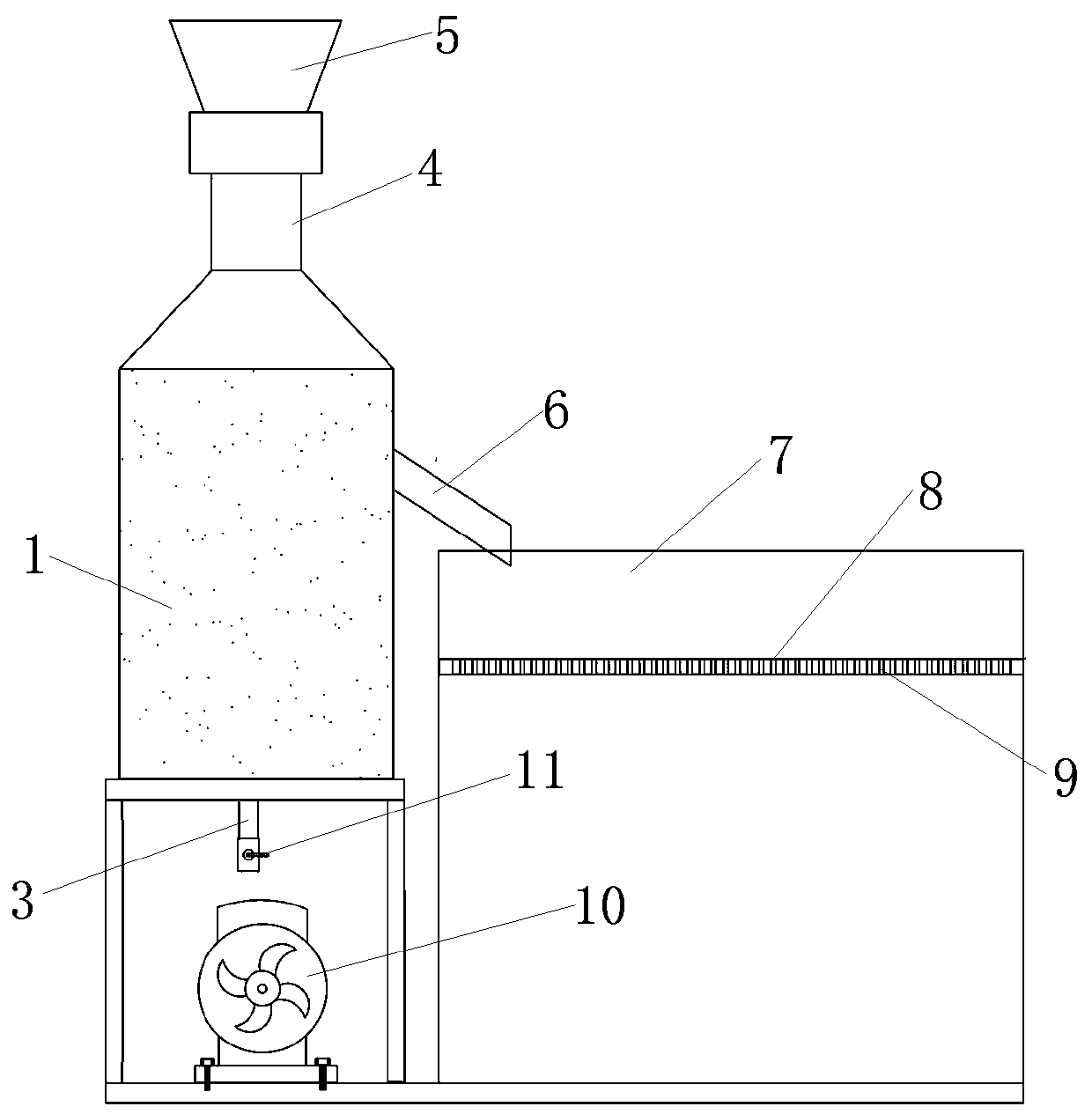

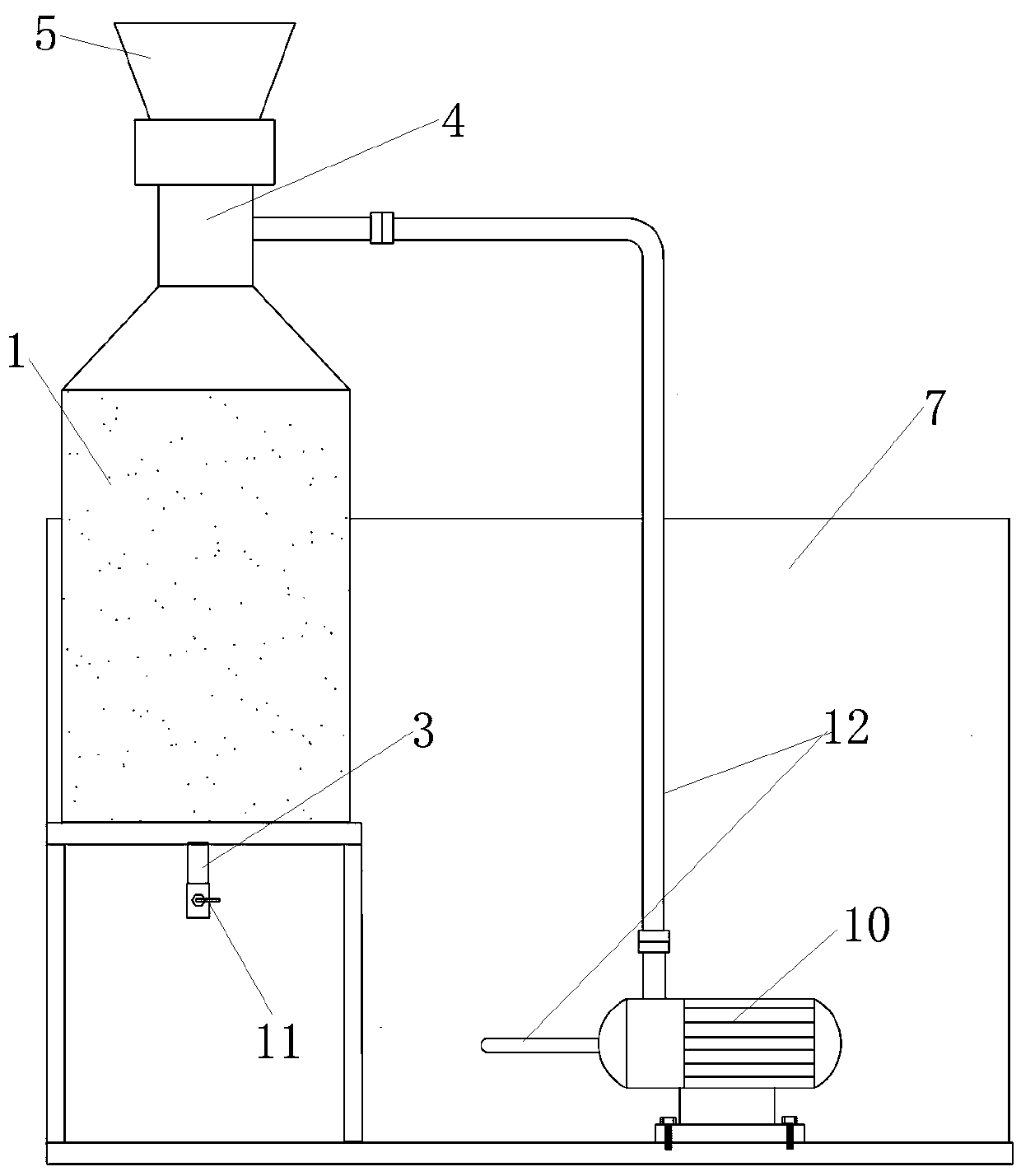

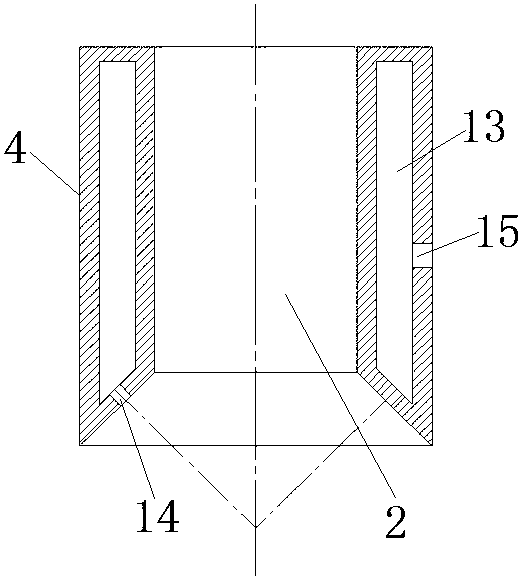

[0026] Example 1 of the alloyed gold powdering device of the present invention, such as Figure 1 to Figure 4 As shown, the combined gold powdering device includes a gold powder collection bucket 1 and a high-pressure water supply system. The upper and lower ends of the gold powder collection bucket 1 are respectively provided with a gold water injection channel 2 and a gold powder discharge channel 3, and a switch valve 11 is provided at the gold powder discharge channel 3. , The high-pressure water supply system is connected with a spray pipe 4, the inner hole of the spray pipe 4 forms a gold water injection channel 2, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com