Hydrogen-consuming apparatus low gas optimization utilization method and hydrogen-consuming apparatus low gas optimization utilization system

A low-separation gas and hydrogen production device technology, applied in separation methods, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of recovery efficiency limitation, hydrogen discharge into the gas system, etc., to reduce load and fuel consumption, prolong The operation cycle and the effect of low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

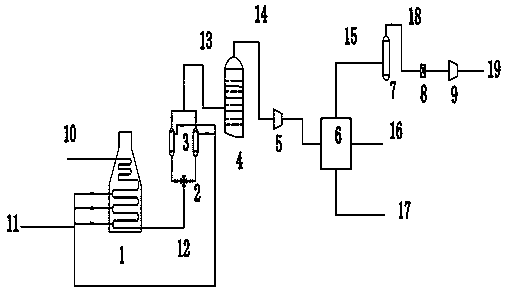

Method used

Image

Examples

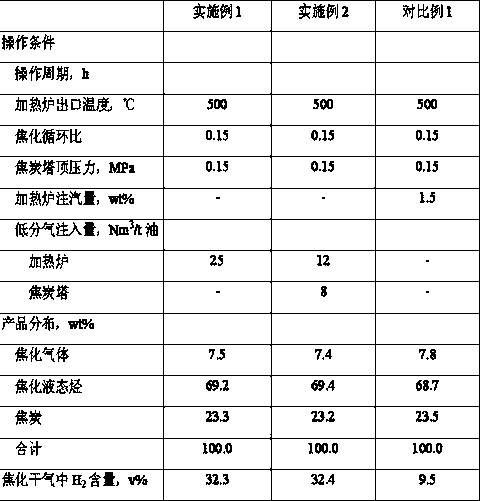

Embodiment 1

[0044] The embodiment is to conduct a test on the delayed coking experimental device according to the flow of the method for optimizing the utilization of low-separation gas of the hydrogen consumption device provided by the present invention, wherein the low-separation gas of the hydrogen consumption device is injected into the heating furnace for radiation through the steam injection point of the coking heating furnace Section, operating conditions and product distribution are shown in Table 3 (the amount of low fraction gas has been deducted from the product yield), it can be seen that the yields of coke and liquid hydrocarbons are 23.3% and 69.2% respectively, and the H 2 The content is 32.3%.

Embodiment 2

[0046] It is basically the same as the embodiment, the difference is that when the coking raw material and the low-separation gas of the hydrogen-consuming device start the coking reaction in the coke tower, another low-separation gas of the hydrogen-consuming device is passed into the coke tower, and the coking reaction The end is to stop feeding, the low-separation gas is injected from the coke tower cylinder at a distance of 4m from the oil and gas outlet at the top of the coke tower, and the injection port is uniformly distributed at three points, and the injection port and the coke tower shell are at 45 degrees . The operating conditions and product distribution are shown in Table 3 (the amount of low fraction gas has been deducted from the product yield). It can be seen that the yields of coke and liquid hydrocarbons are 23.2% and 69.4% respectively, and the H in coking dry gas 2 The content is 32.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com