High-strength high-toughness high-carbon bainite steel and preparation method thereof

A technology of high carbon bainite steel and carbon bainite steel, which is applied in the field of material preparation, can solve the problems of complex production process, increase production cost, high requirements on equipment and process conditions, etc., achieve simple process, improve strength and toughness, The effect of excellent strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A kind of preparation method of high-strength high-toughness high-carbon bainite steel of the present invention comprises the following steps:

[0024] In terms of percentage, the high carbon bainite steel contains the following chemical composition: C: 0.6%-0.9%; Si: 1.5-2.5%; Mn: 1.5%-2.5%; Cr: 0.5-1.5%; Mo: 0.1 -0.3%; the rest is Fe and unavoidable impurity elements;

[0025] S1. According to the chemical composition described in claim 1, the cast billet of alloy steel is obtained by vacuum smelting, and then the cast billet is hot-rolled into a forging billet of the required size, without high-temperature annealing, directly heated at 1150-1250 °C , take out after 1-2h soaking and heat preservation, hot rolling, and cool in the air;

[0026] S2. Austempering heat treatment process:

[0027] The first step: directly heat the rolled steel billet to 900-950°C, and keep it warm for 0.5-1.5h to make the whole structure austenitized; the second step: heat the austenitiz...

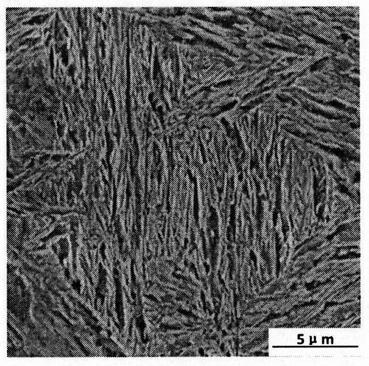

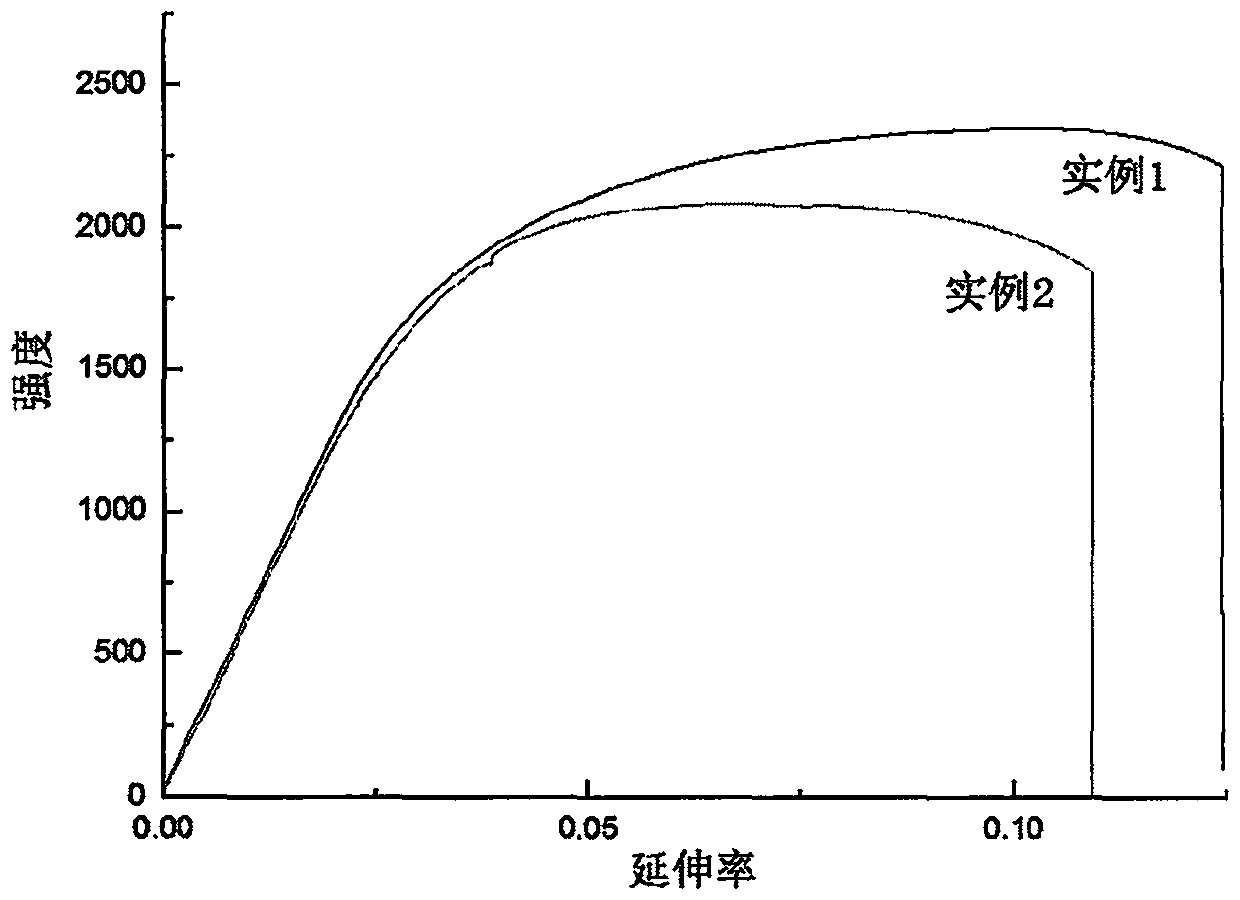

Embodiment 1

[0030] A method for preparing high-strength and high-toughness high-carbon bainitic steel, the high-carbon bainitic steel contains the following chemical components: C: 0.6%-0.9%; Si: 1.5-2.5%; Mn: 1.5%-2.5% %; Cr: 0.5-1.5%; Mo: 0.1-0.3%; the rest is Fe and unavoidable impurity elements;

[0031] S1. According to the chemical composition described in claim 1, the cast billet of alloy steel is obtained by vacuum smelting, and then the cast billet is hot-rolled into a forging billet of the required size, without high-temperature annealing, directly heated at 1150-1250 °C , take out after 1-2h soaking and heat preservation, hot rolling, and cool in the air;

[0032] S2. Austempering heat treatment process:

[0033] The first step: directly heat the rolled steel billet to 900-950°C, and keep it warm for 0.5-1.5h to make the whole structure austenitized; the second step: heat the austenitized bainite steel with 10 The cooling rate of -20°C / s is reduced to 200-220°C, placed in a s...

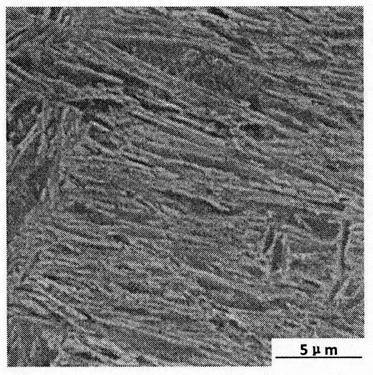

Embodiment 2

[0036] A method for preparing high-strength and high-toughness high-carbon bainitic steel, the high-carbon bainitic steel contains the following chemical components: C: 0.6%-0.9%; Si: 1.5-2.5%; Mn: 1.5%-2.5% %; Cr: 0.5-1.5%; Mo: 0.1-0.3%; the rest is Fe and unavoidable impurity elements;

[0037] S1. According to the chemical composition described in claim 1, the cast billet of alloy steel is obtained by vacuum smelting, and then the cast billet is hot-rolled into a forging billet of the required size, without high-temperature annealing, directly heated at 1150-1250 °C , take out after 1-2h soaking and heat preservation, hot rolling, and cool in the air;

[0038] S2. Austempering heat treatment process:

[0039] The first step: directly heat the rolled steel billet to 900-950°C, and keep it warm for 0.5-1.5h to make the whole structure austenitized; the second step: heat the austenitized bainite steel with 10 The cooling rate of -20°C / s is reduced to 220-250°C, placed in a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap