Method and device for detecting thread size parameter of oil tube

A thread size and parameter detection technology, applied in the field of digital image acquisition of parts, ordinary thread and other parts size detection fields, can solve the problems of easy wear of the probe, low degree of automation, complicated operation, etc., which is conducive to accurate processing and low installation cost. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

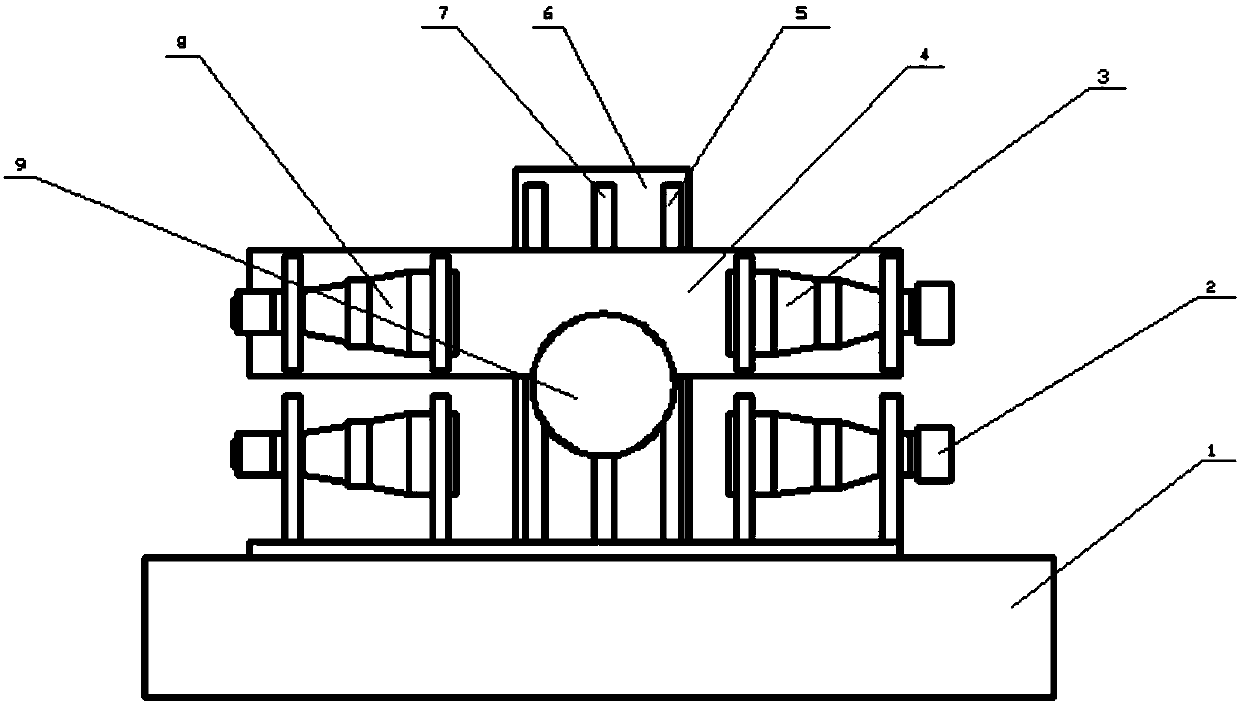

Image

Examples

Embodiment 1

[0033] Camera calibration measurement, install the component with known contour size on the processing station of the part to be measured, adjust the proper position so that the upper and lower edges fall within the angle of view of the two cameras, take a contour image, set the camera gain and shutter time, and collect the image. Two gray-scale digital images of the upper and lower sections of the calibration part are obtained, the edge contours of the two images are extracted, and the positional relationship between the two cameras is calibrated through the relative positions of the contour lines.

Embodiment 2

[0035] Thread geometry measurement: place the thread to be measured while keeping the position of each device, collect two grayscale images of the upper and lower interface of the thread, extract the edge of the thread contour in the image, find the upper and lower edges of the thread teeth, and calculate the equation of the straight line where the upper edge and the lower edge are located , the distance between the two straight lines is the tooth height of the thread; find a parallel straight line between the two straight lines, which has an intersection point with the edge of the threaded gear, and the distance between each skipped intersection point is the pitch; use the extracted contour edge and Use calibration to calculate its cone angle and diameter. The above parameters, or the calibration data used, are all calculated geometrically to obtain the geometric dimension parameters of the thread section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com